Yuqori voltajli ilovalarda IGBT modullariga kirish

IGBT modullari nima?

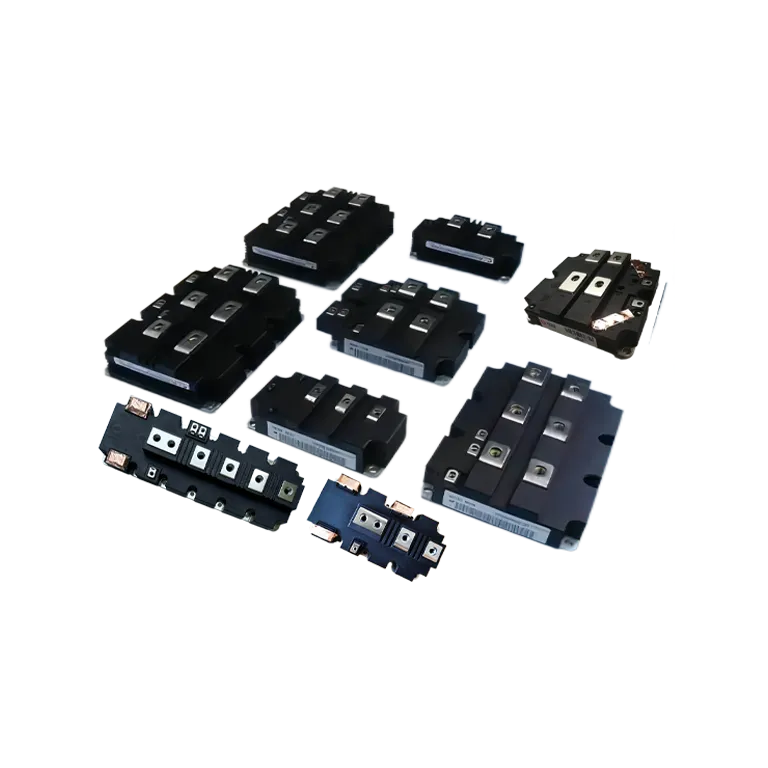

Insulyatsiya qiluvchi tashabbusli bipolyar tranzistorlar (IGBT) modullari yuqori kuchlanish bilan ishlovchi tizimlarda kalitlash va quvvatni boshqarish vazifalarini bajaruvchi yarimo'tkazgichli komponentlar sifatida muhim rol o'ynaydi. Ishlab chiqaruvchilar bir nechta IGBT tranzistorlarni bitta modulga joylashtirganda, ular alohida ishlatilganda bo'lgan natijalarga qaraganda yaxshiroq natija beradi. Birlashtirilgan dizayn ushbu qurilmalarning ishlash samaradorligini yaxshilaydi, ularning xizmat muddatini uzaytiradi va issiqlikni boshqarishda samarali yordam beradi. Eng ko'p hollarda IGBT modullari o'zgartirgichlar va konvertorlarning ichida ishlaydi, ular yuqori kuchlanishli elektr energiyasini o'zgartirish va nazorat qilishda yordam beradi, energiyani sarflamaydi. IGBT larning ayniqsa ajoyib tomoni ularning bipolyar tutashtirish tranzistorlari hamda MDP (metall-oksid yarimo'tkazgich maydon effekti tranzistorlari) larning xususiyatlarini birlashtirish qobiliyatida. Shu noyob kombinatsiya tufayli IGBT modullari hozirgi kunda quyosh energiyasi o'rnatishlaridan boshlab, shamol fermalarigacha, elektr avtomobillardan hamda mamlakatlarning temir yo'llarida harakatlanuvchi poyezdlargacha bo'lgan sohalarda keng qo'llanilmoqda.

Asrasho chaqon tizimlari dagi muhimlik

IGBT modullar bugungi kunda uchratadigan yuqori kuchlanishli tizimlarda energiyani o'zgartirishni samarali qilishda muhim rol o'ynaydi. Ular energiya sarfini kamaytiradi va umuman olganda tozaroq ishlashga yordam beradi. Endi esa bu modullar hamma joyda uchrab turgani ham kuzatilmoqda. Shamol fermalari ularga ehtiyoj sezadi, elektr avtomobillari ularga tayanadi, hatto baland tezlikdagi poyezdlar ham IGBT texnologiyasiga tayangan holda tezlikni saqlab, energiyani tejashni amalga oshiradi. Bozor bo'yicha hisobotlar esa qiziqarli ma'lumot berdi. Sanoat IGBT lardan qat'iy nazar qaram bo'lib qolganligi hamda 2027-yilgacha har yili taxminan 6,5% o'sish kutilayotgani ko'rsatilmoqda. Bu mantiqiy ham, chunki turli sohalardagi kompaniyalar bir vaqtda ham o'zlarining karbon izini kamaytirish hamda mablag' tejashni xohlaydilar. IGBT larni ajratib turuvchi narsa nima? Oddiy komponentlar bosim ostida ishlolmaydigan qiyin vazifalarni bajarishda ular kuchlanish oqimini boshqarishda zamonaviy alternativlardan ustun turadi.

IGBT modullarining muassir quvvat tarmoqlaridagi rol

Effektiv quvvat yetkazishini ta'minlash

IGBT modullari uzun masofaga quvvat berishda uning ko'p qismini yo'qotmasdan yetkazib berishda muhim rol o'ynaydi. Yarimo'tkazgichli komponentlar sifatida ular o'tkazish jarayonida sodir bo'ladigan noqulay quvvat yo'qotishlarni kamaytiradi va butun tarmoqning samarali ishlashini ta'minlaydi. Asl sir shundaki, bu modullar tez holatni o'zgartira olish qobilyatiga ega, bu foydalanuvchilarga elektr oqimining oqishini aniqroq nazorat qilish imkonini beradi. Bu esa iste'molchilarga kerak bo'lgan narsalarni taklif bilan muvozanatlash imkonini beradi. Raqamli kuzatish tizimlari kabi yangi texnologiyalar bilan birlashtirilganda IGBT modullari aqlli tarmoqlarda yanada qimmatli bo'ladi. Ko'plab mutaxassislarning fikricha, aynan shu jihatlari zamonaviy tarmoqlarning energiya talablari ortib borayotgan sharoitda ham samarali va ishonchli bo'lishiga yordam berayotdi.

Tarmoq stabilligi va vosita energiya integratsiyasi

Zamonaviy kuch tarmoqlariga IGBT modullarini qo'shish sistema barqarorligini yaxshilashga yordam beradi, quyosh paneli va shamol turbinasi kabi bashoratsiz bo'lgan yangi energiya manbalari bilan ishlaganda aynan shu kerak bo'ladi. Bu modullarni qanday qilib foydali qiladi? Ularning kerimsiz bo'lgan kuchlanish tebranishlarini yaxshi nazorat qiladi, hatto talab birla oshib ketganda ham hamma narsani silliq ishlashini ta'minlaydi. Hukumatlar tomonidan tozaligini rag'batlantirishga qaratilgan harakatlar kuchayib borayotganda, bu jihat ayniqsa muhim bo'lib qolmoqda. Elektr kompaniyalari yangi manbalardan kelib tushayotgan o'zgaruvchan kirishlarni muvozanatlash vaqtida endi elektr tarmog'ini o'chirib qo'yishlari mumkin emas. Shu sababli ham IGBT texnologiyasi an'anaviy hamda yangi energiya manbalari bilan ishlaydigan ishonchli elektr tarmog'ini yaratmoqchi bo'lgan har biri uchun deyarli kerakli bo'lib qolmoqda.

Misol: Eshik va surxonda fermalari uchun qo'llanma

So'nggi o'rnatishlarni kuzatib, shamol elektr stansiyalari va quyosh paneli majmualarida IGBT modullar elektr energiyasini toza ishlab chiqarishdan foydali elektrgacha aylantirishda aniq farq hosil qilayotganini ko'ramiz. Maydon hisobotlari IGBT texnologiyasi quvvat oqim dinamikasi ustidan aniqroq nazorat olib borish imkonini berayotganligi sababli ushbu tizimlarning natijaviy ko'rsatkichlari sezilarli darajada yaxshiroq ekanligini ko'rsatmoqda. Bu xususiyat ayniqsa qiziqki, IGBT modullar turli qayta tiklanuvchi energiya sozlamalarida qanchalik moslashuvchan ekanligini namoyish etadi - o'zgaruvchan shamol tezligi yoki o'zgaruvchan quyosh nuri chariqish bilan ishlashda ham. Elektr tarmog'iga ulash muammolarini hal qilishda ishtirok etayotgan muhandislar tez-tez IGBT modullarni o'yin qoidasini o'zgartiruvchi vositaga aylantirishayotganligini aytishadi. Ko'proq mamlakatlar tozaroq elektr tarmoqlarini joriy etishga harakat qilayotgan sari yarim o'tkazgichli komponentlarning roli nazariy toza energiya potensiali bilan amaliy etkazib beriladigan quvvat o'rtasidagi bo'shliqni to'ldirishda yanada muhimroq ahamiyat kasb etmoqda.

Temir yo‘llari tizimlarida IGBT modullari: elektrifikatsiya va effektivlik

Elektrik lokomotiflari ichida quvvatni boshqarish

IGBT modullar temir yo'l tizimlari elektrifikatsiyaga o'tgani sari muhimroq bo'lib bormoqda, elektr lokomotivlarning to'g'ri ishlashi uchun kerak bo'lgan nozik darajadagi quvvat nazoratini ta'minlaydi. Ushbu modullar traditsion tizimlar qilolmaydigan tezlikka erishish imkonini beradi, shu sababli ham Yevropa va Osiyoning zamonaviy yuqori tezlikdagi temir yo'l tarmoqlarida keng qo'llanilmoqda. Temir yo'l operatorlari IGBT texnologiyasidan foydalanishda umumiy ishlash samaradorligi yaxshilanayotganini aytishmoqda. Poyezdlar bekatlar orasida silliqroq harakat qiladi va ta'mirlash brigadalarining ma'lumotlariga ko'ra, yo'lovchilar harakati eng ko'p bo'lgan davrda nosozliklar kamroq uchrab turibdi. Ishlab chiqaruvchilar o'z ishlanmalariga bu modullarni kiritish boshlaganda, odatda vaqt o'tishi bilan yoqilg'i xarajatlari 15-20% kamayishini kuzatishadi, yo'lovchilar esa xizmat ko'rsatish sifatida bir xil bo'lib turishini his qiladilar.

Energiya effektivligi va karbon izining kamayishi

IGBT modullar temir yo'l tizimlarida energiya samaradorligini haqiqiy ravishda yaxshilaydi, ayniqsa zamonaviy poyezdlarda uchratadigan qayta tiklanuvchi tormozlash tizimlarida. Bu tizimlarning ishlash usuli juda qiziqarli, chunki poyezd sekinlashayotganda kinetik energiya ishlatilmaydigan issiqlikka aylanmasdan saqlanadi. Bu esa umumiy oqim manbalaridan kamroq quvvat olish zarurati tug'diradi, natijada elektr energiyasi xarajatlari hamda CO2 chiqindilari kamayadi. Dunyo bo'ylab ko'plab transport boshqarmalari IGBT texnologiyasiga o'tishmoqda, chunki bu ularning iqlim maqsadlariga erishishda hamda ishonchli xizmat ko'rsatishda yordam beradi. Ba'zi shaharlar o'tgandan keyin energiya xarajatlarida 30% gacha tejashganligi haqlidir, bu esa poyezdlarning kuniga kun ishlashi hisobiga tushunarli.

Harakat va To'xtash Sistemalari uchun Tez Javob

IGBT modullari tez javob berish vaqti tufayli elektr poyezdlarning tortish va tormozlash tizimlariga haqiqiy ishlash samaradorligini oshiradi. Ular yuqori o'zgarish chastotalarini boshqaradi, shu bilan birga sharoit kunidan kun o'zgarsa ham barqarorlikni saqlaydi. Ba'zi tadqiqotlar shuni ko'rsatdiki, bu modullar to'xtash masofasini qisqartiradi va jurnallar davomida noqulay to'xtashlar va boshlanishlarga bog'liq shikoyatlarni kamaytiradi. Yo'lovchilar uchun bu esa xavfsizroq sayohat qilish imkonini beradi.

Yuqori Voltajdagi IGBT Modullardagi Texnologik Innovatsiyalar

Mutasarrif Voltajni Boshqarish (4.5 kV gacha)

IGBT modullari endi 4,5 kV kuchlanishlarga chidash imkoniyatiga ega bo'ldi, bu ularni qiyinotli sanoat dasturlari uchun muhim qismlar qilib qo'ydi. Yuqori kuchlanishlarni boshqarish qobiliyati esa katta infratuzilma loyihalarida elektr ta'minotini yanada samarali qiladi. Bu juda qiziq bo'lsa ham, amaliyotda qanday ishlashi ahamiyatga ega. Tizimlar yuqori kuchlanishda ishlayotganda, ularning ishonchliligi ham oshadi, chunki narsalarning ishdan chiqish ehtimoli kamayadi. Shundan keyin muhandislarga elektr sxemalarini loyihalashda endi shuncha ko'p alohida komponentlarga ehtiyoj qolmaydi, bu esa ishlarni ancha soddalashtiradi.

Issiq boshqaruvida etkazilgan muvaffaqiyatlar

Yangi issiqlikni boshqarish texnologiyasi IGBT modullarining ishlash samaradorligini va ularning xizmat muddatini keskin oshirdi, ayniqsa yuqori kuchlanish bilan ishlaganda. Ortiqcha issiqlikni to'g'ri chiqarib tashlash modulni qattiq yuklamalarda ham ishonchli ishlashini ta'minlaydi. Tadqiqotlar shuni ko'rsatdiki, yaxshiroq sovutish usullari modullarning ishlash samaradorligini 15% ga oshirishi mumkin. Bunday yaxshilanish elektr energiyasining uzluksiz va kuchli bo'lishi talab qilinadigan sohalarda ayniqsa muhim ahamiyatga ega.

Struktura qayta dizayn orqali ishonch oshirish

Eng so'nggi o'zgarishlar IGBT moduli dizaynlari qattiq sharoitlarga duch kelganda ularni yanada uzoqroq xizmat qilishini ta'minlashga qaratilgan. Yaxshi materiallar bilan aqlliroq qadoqlashni birlashtirish modullarning kuchli yuklamalarga chidamligini sezilarli darajada oshirgan. Ko'plab odamlar bu takomillashtirishlarni faqat tashqi qavat deb hisoblaydi, lekin aslida ular katta farq yaratadi. Ba'zi sanoat mutaxassislari esa mazkur o'zgarishlar tufayli ta'mirlash xarajatlari vaqt o'tishi bilan 30% atrofida kamayishini aytishadi. Mazkur turdagi tejashlar mazkur modullarni kuniga kun qiyinuvchi sanoat muhitida ishlatayotgan kompaniyalar uchun katta ahamiyatga ega.

Keng Bandgap Materiallari: SiC va GaN integratsiyasi

Keng yarim o'tkazgichli materiallar, masalan, kremniy karbid (SiC) va galliy nitrid (GaN) kabi materiallarni kiritish IGBT modullarini yaratish usulini o'zgartirmoqda. Bu materiallarning afzalliklari nima? Oddiygina ular yaxshiroq ishlaydi. Yuqori samaradorlik yaxshilangan issiqlik uzatish bilan birlashganda modullar yuqori harorat sharoitida ham yaxshi ishlashi mumkinligini anglatadi. Hozirgi bozor tendentsiyalarini hisobga olsak, ishlab chiqaruvchilarning aksariyati loyihalarida SiC va GaNga murojaat qilmoqda. Yarimo'tkazgich sanoasida ham mana shu o'tish kuzatilmoqda, chunki kompaniyalar haqiqiy natijalarni beruvchi yangi materiallar bilan uskunalarni yangilashni xohlaydi. Oqilona elektronika sohasida rivojlanish davom etayotganda, turli sanoat sohalarida yuqori kuchlanishli komponentlarni loyihalash va joriy qilishda asosiy o'zgarishlar sodir bo'layotgani kuzatilmoqda.

Xulosa â Yuqori kuchlanishli sanoatda IGBT modullarining kelajagi.

Yetib borishda, IGBT modullari texnologiya va dizayn innovatsiyalaridagi doimiy takomillashtirish tufayli yuqori kuchlanishli sohalarda muhim rol o'ynashga tayyor. Bunga Infineon Technologies AG kabi kompaniyalar ham kiradi, ular ushbu modullarni yanada samarali qilish va o'lchamlarini kichraytirish ustida ishlayapdi. Sanoat uchun bu esa elektr ta'minot tizimlarini qayta sozlash imkonini beradi va operatsiyalar avvalgiga qaraganda yaxshiroq boshqariladi. Transport kompaniyalari elektr transport vositalari uchun allaqachon shu modullarga tayanmoqda, qurilish uskunalari ishlab chiqaruvchilari ham shu yo'nalishda qadam qo'ydi. Mazkur tendentsiya esa yaqqol sekinlash belgilari ko'rsatmayapti.

Tez-tez so'raladigan savollar

IGBT modullari nimaga ishlatiladi?

IGBT модулари инверторлар, конвертерлар, таъминотли энергия системалари ва электр мобайлар сифатидаги кучли ёндастарда кучни эффиентли рўйхатга олиш ва босиш учун ишлатилади.

IGBT модулари қандай энергия эффиентлилигини узгартади?

IGBT модулари ҳарбий куч йиғиликларидан фойдаланадigan ва турлиLOYIHLARDA кучни асосий рўйхатга олиш ва регулировка қилиш учун эффиентлидир.

Нима янгилаштуришлар IGBT модуларини янгилаштиради?

Янги янгилаштуришлар СиС ва ГаН кabi широатли материалларингиз билан интеграцияси, структурал可靠性ни янгилаштуриш, инновация термик управление ва куч йиғиликисини янгилаштуришга олади.

IGBT модулари қандай экологик субсистемага кўмак кўради?

Куч эффиентлилигини узгартиш ва таъминотли энергия интеграциясини яратиш орқали IGBT модулари дунё ечими мақсадларига қол йоришиб, карбон ичкинчаларини камайтириб ташлади.

Mundarija

- Yuqori voltajli ilovalarda IGBT modullariga kirish

- IGBT modullarining muassir quvvat tarmoqlaridagi rol

- Temir yo‘llari tizimlarida IGBT modullari: elektrifikatsiya va effektivlik

- Yuqori Voltajdagi IGBT Modullardagi Texnologik Innovatsiyalar

- Xulosa â Yuqori kuchlanishli sanoatda IGBT modullarining kelajagi.

- Tez-tez so'raladigan savollar