industrial control ic

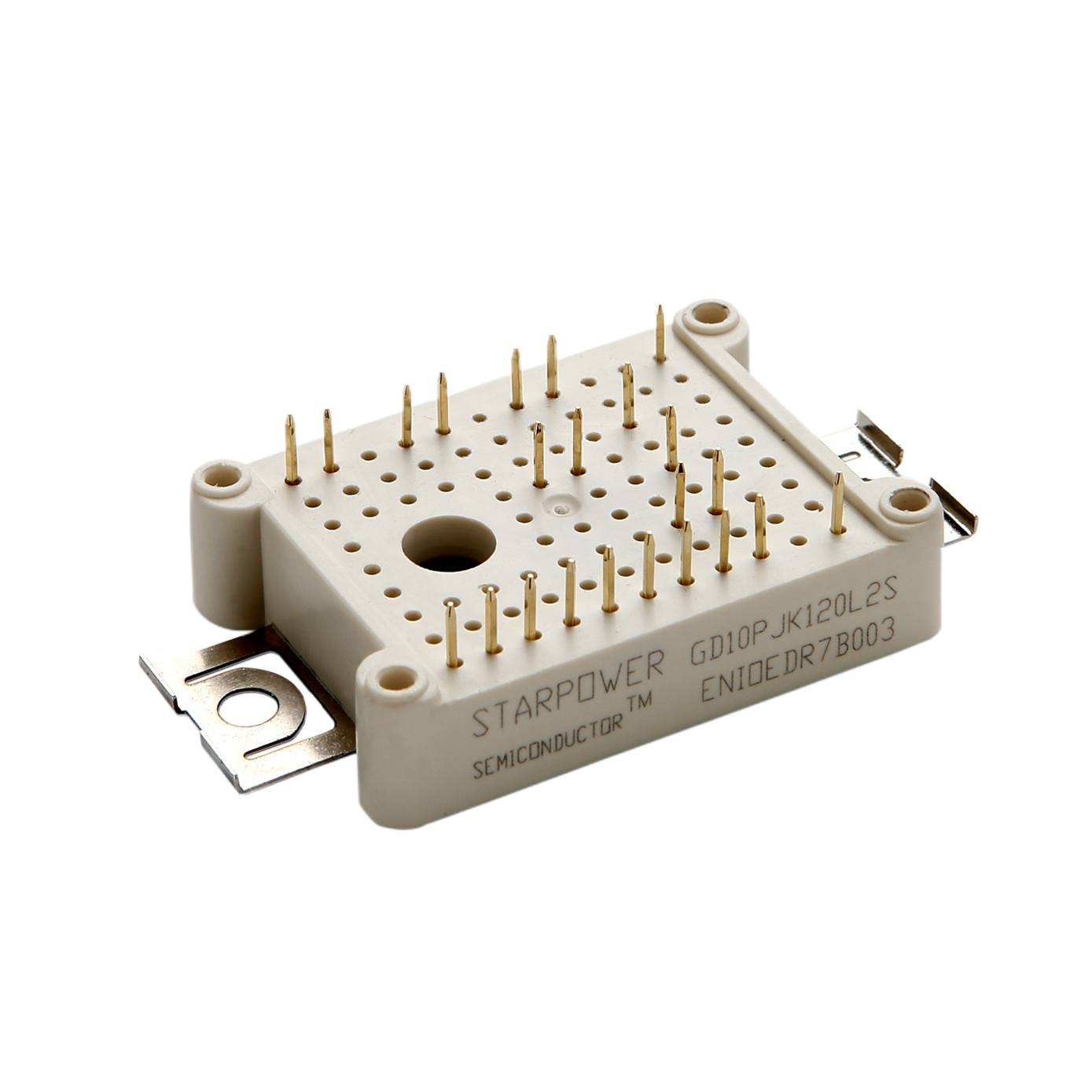

Industrial control IC represents a fundamental component in modern automation systems, serving as the brain behind countless manufacturing processes worldwide. These specialized integrated circuits are engineered to manage, monitor, and control various industrial operations with exceptional precision and reliability. An industrial control IC typically incorporates multiple functions including signal processing, data acquisition, communication protocols, and real-time decision-making capabilities. The primary function of these circuits involves converting analog signals from sensors into digital data, processing this information according to predetermined algorithms, and generating appropriate control outputs to actuators and other devices. Advanced industrial control IC units feature built-in protection mechanisms against electromagnetic interference, voltage fluctuations, and temperature extremes that are common in harsh industrial environments. These circuits support multiple communication standards such as Modbus, CAN bus, and Ethernet protocols, enabling seamless integration with existing automation networks. The technological architecture of industrial control IC incorporates high-speed processors, dedicated memory banks, and specialized input-output interfaces designed for industrial applications. Many modern versions include programmable logic controllers functionality, allowing users to customize control algorithms without hardware modifications. The circuits offer exceptional timing accuracy, often maintaining microsecond-level precision in control loops, which is crucial for high-speed manufacturing processes. Industrial control IC systems typically feature modular designs that allow for easy expansion and maintenance. These components support both centralized and distributed control architectures, providing flexibility in system design and implementation. The integration of artificial intelligence and machine learning capabilities in newer industrial control IC models enables predictive maintenance and adaptive control strategies that optimize performance automatically.