In today's rapidly evolving electronics landscape, selecting the right precision DAC has become increasingly critical for engineers developing high-performance systems. A precision DAC serves as the crucial bridge between digital control systems and analog outputs, making it essential to understand the key specifications and performance characteristics that differentiate exceptional components from standard alternatives. Whether you're designing industrial automation equipment, test and measurement instruments, or advanced audio systems, the choice of precision DAC directly impacts your system's accuracy, stability, and overall performance capabilities.

Understanding Precision DAC Fundamentals

Core Architecture and Operating Principles

A precision DAC fundamentally converts digital input codes into corresponding analog voltage or current outputs with exceptional accuracy and minimal deviation. The architecture typically employs advanced techniques such as segmented designs, where higher-order bits utilize thermometer-coded arrays while lower-order bits use binary-weighted structures. This hybrid approach optimizes both linearity performance and silicon efficiency, enabling precision DAC implementations to achieve superior specifications compared to conventional architectures.

Modern precision DAC designs incorporate sophisticated calibration mechanisms that continuously monitor and correct for temperature drift, aging effects, and process variations. These self-calibrating systems utilize internal reference measurements and digital correction algorithms to maintain specified accuracy levels throughout the operational lifetime. The calibration process typically occurs during power-up sequences and can be triggered periodically during normal operation to ensure consistent performance.

Signal Chain Integration Considerations

When implementing a precision DAC within a complete signal chain, engineers must carefully consider the interaction between the converter and surrounding circuitry. The output amplifier selection becomes particularly critical, as it must preserve the precision DAC's inherent accuracy while providing adequate drive capability for the intended load conditions. Low-noise, high-precision operational amplifiers with carefully matched offset and drift characteristics ensure optimal system-level performance.

Power supply design represents another crucial aspect of precision DAC integration, as supply noise and regulation directly affect conversion accuracy. Dedicated linear regulators with excellent power supply rejection ratios, combined with extensive decoupling networks, help maintain the clean operating environment necessary for precision performance. Additionally, careful PCB layout techniques minimize ground loops and ensure proper current return paths for optimal noise performance.

Critical Specifications for Precision DAC Selection

Resolution and Accuracy Parameters

Resolution defines the smallest incremental change a precision DAC can produce, typically expressed in bits, while accuracy encompasses the absolute deviation between the ideal and actual output values. For precision applications, engineers often require 16-bit, 18-bit, or even 20-bit resolution levels to achieve the necessary granularity in output adjustments. However, true effective resolution may differ from the specified bit count due to noise limitations and other non-ideal characteristics that reduce the meaningful resolution.

Integral nonlinearity and differential nonlinearity specifications quantify how closely the precision DAC's transfer function matches the ideal straight-line relationship between input codes and output levels. INL typically measures the maximum deviation of any code from the ideal transfer function, while DNL indicates the variation in step sizes between adjacent codes. Premium precision DAC devices maintain INL specifications better than ±1 LSB and DNL better than ±0.5 LSB across the full operating range.

Dynamic Performance Characteristics

Settling time represents a fundamental dynamic specification that determines how quickly a precision DAC reaches its final output value within a specified accuracy band following an input code change. This parameter becomes particularly important in closed-loop control systems where rapid response times directly impact system stability and performance. Advanced precision DAC architectures achieve settling times in the microsecond range while maintaining full accuracy specifications.

Output noise and drift characteristics significantly influence long-term stability and measurement precision in sensitive applications. Voltage noise density specifications, typically measured in nV/√Hz, indicate the broadband noise contribution of the precision DAC to the overall system noise floor. Temperature drift coefficients, expressed in ppm/°C, quantify how output levels change with temperature variations, making this specification critical for applications operating across wide temperature ranges.

Domestic Precision DAC Solutions and Market Leaders

Leading Chinese Manufacturers

The domestic precision DAC market has experienced remarkable growth, with several Chinese manufacturers establishing strong positions in both domestic and international markets. Companies like Analogix, ChipSea, and Sgmicro have developed comprehensive portfolios of precision DAC products that compete effectively with established international suppliers. These manufacturers leverage advanced semiconductor processes and innovative design techniques to deliver high-performance solutions at competitive price points.

Domestic precision DAC manufacturers have invested heavily in research and development, resulting in products that meet stringent automotive, industrial, and communications requirements. Many of these companies maintain ISO 9001 quality management systems and have achieved automotive qualification standards, demonstrating their commitment to reliability and performance consistency. The combination of local technical support, shorter supply chains, and cost advantages makes domestic precision DAC solutions increasingly attractive for Chinese OEMs.

Product Portfolio Analysis

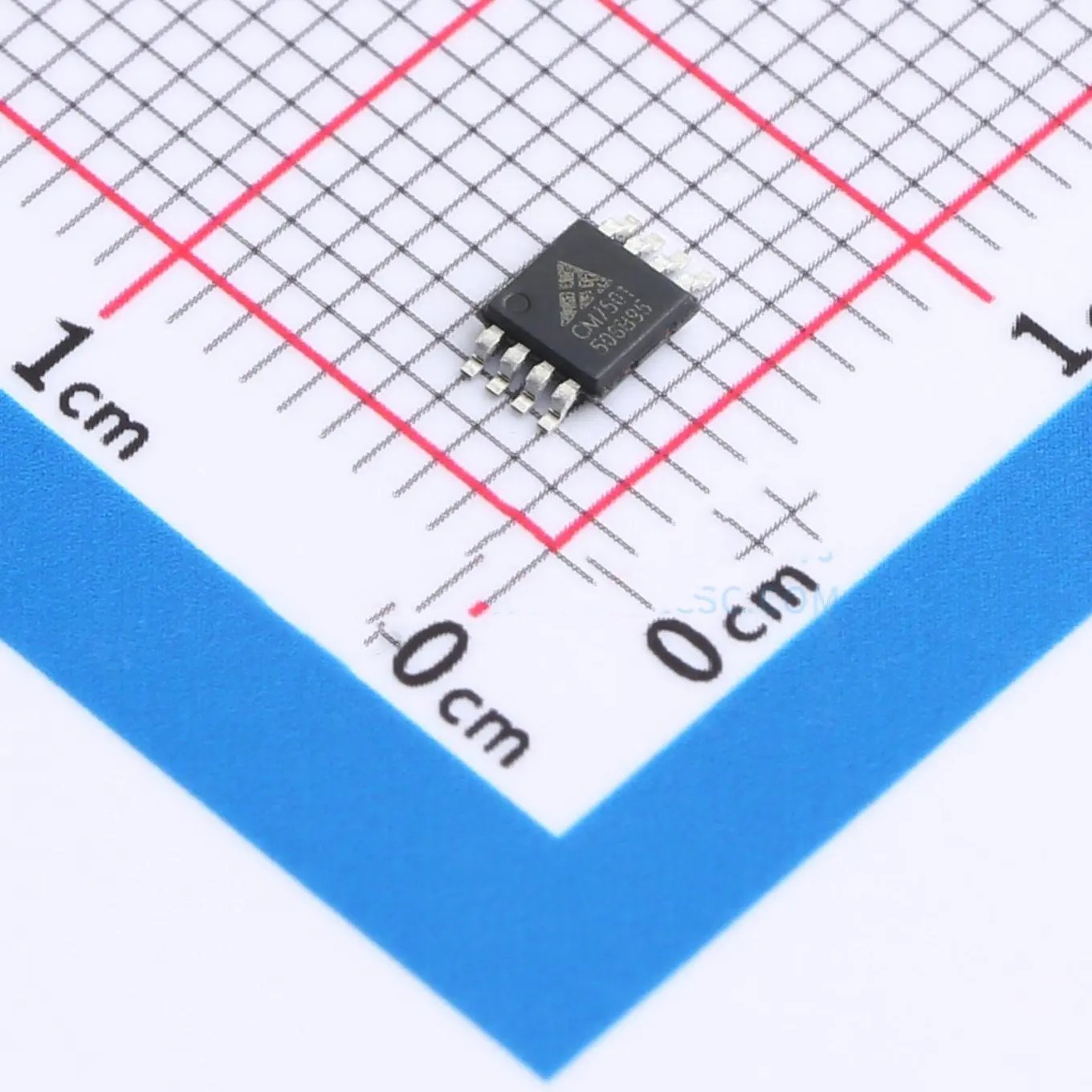

Current domestic precision DAC offerings span resolution ranges from 12-bit to 20-bit, with various output configurations including voltage and current modes. Many manufacturers provide pin-compatible alternatives to popular international precision DAC products, simplifying the design-in process for existing applications. These devices typically feature advanced packaging options, including small-outline packages and chip-scale packages that support miniaturization requirements.

Specialized precision DAC variants target specific application segments such as industrial automation, where extended temperature ranges and enhanced electromagnetic compatibility become essential. Some manufacturers offer application-specific integrated circuits that combine precision DAC functionality with additional signal conditioning circuitry, reducing component count and improving overall system integration. These integrated solutions often provide superior performance compared to discrete implementations while reducing board space requirements.

Application-Specific Selection Criteria

Industrial Automation Requirements

Industrial automation applications demand precision DAC devices that can operate reliably in harsh environmental conditions while maintaining accuracy specifications over extended periods. Temperature stability becomes paramount, as industrial equipment often operates in environments with significant temperature variations throughout daily and seasonal cycles. Precision DAC devices intended for industrial use typically specify operation across -40°C to +105°C temperature ranges with minimal performance degradation.

Electromagnetic compatibility requirements in industrial environments necessitate precision DAC designs with robust immunity to conducted and radiated interference. Advanced packages with enhanced shielding characteristics and integrated filtering help maintain signal integrity in electrically noisy environments. Additionally, industrial-grade precision DAC components undergo extended reliability testing, including high-temperature operating life tests and thermal cycling evaluations to ensure long-term operational stability.

Test and Measurement Applications

Test and measurement systems require precision DAC components with exceptional accuracy and stability characteristics to serve as reference sources and calibration standards. These applications often demand the highest available resolution levels, with 18-bit and 20-bit precision DAC devices becoming increasingly common in high-end instrumentation. Calibration traceability and long-term stability specifications become critical factors in the selection process for these demanding applications.

Measurement uncertainty budgets in precision test equipment allocate specific error contributions to each system component, making precision DAC specifications a crucial factor in overall system accuracy. Low-frequency noise characteristics, particularly 1/f noise contributions, significantly impact measurement precision at longer integration times. Premium precision DAC devices incorporate advanced noise reduction techniques and reference designs to minimize these low-frequency noise sources.

Design Implementation Best Practices

PCB Layout and Grounding Strategies

Proper PCB layout techniques play a crucial role in realizing the full performance potential of precision DAC devices. Ground plane design must carefully separate analog and digital ground domains while providing low-impedance return paths for high-frequency currents. Star grounding configurations help minimize ground loops and reduce coupling between sensitive analog circuits and switching digital logic. Critical precision DAC signals require dedicated routing with appropriate trace impedance control and minimal via usage.

Power supply distribution networks must maintain clean, stable voltages to precision DAC devices while minimizing supply-induced noise coupling. Dedicated power planes with appropriate decoupling capacitor placement help achieve optimal supply rejection performance. Local regulation using low-dropout linear regulators provides additional isolation from system-level supply variations, particularly important for battery-powered portable applications where supply voltages may vary significantly during operation.

Thermal Management Considerations

Thermal design significantly impacts precision DAC performance, as temperature variations directly affect accuracy specifications and long-term stability. Careful component placement minimizes thermal gradients across the precision DAC device, while thermal vias and heat spreading techniques help dissipate generated heat effectively. In high-power applications, dedicated heat sinks or thermal pads may be necessary to maintain junction temperatures within specified limits.

Temperature monitoring and compensation schemes can further enhance precision DAC performance in applications with significant thermal variations. Some advanced implementations incorporate temperature sensors adjacent to precision DAC devices, enabling software-based compensation algorithms to correct for known temperature coefficients. This approach allows systems to maintain accuracy specifications across wider temperature ranges than would be possible with hardware alone.

FAQ

What resolution precision DAC do I need for my application

The required precision DAC resolution depends on your specific accuracy requirements and system noise floor. For general industrial control applications, 12-bit to 16-bit resolution typically provides adequate performance. However, high-precision measurement systems, audio applications, or scientific instrumentation may require 18-bit to 20-bit precision DAC devices to achieve the necessary dynamic range and accuracy levels.

How do I minimize noise in precision DAC implementations

Noise minimization in precision DAC systems requires attention to power supply design, PCB layout, and component selection. Use dedicated linear regulators with excellent power supply rejection, implement proper grounding techniques with separate analog and digital ground planes, and select low-noise operational amplifiers for output buffering. Additionally, consider the precision DAC's internal noise specifications and choose devices optimized for your specific noise requirements.

What are the key differences between domestic and international precision DAC suppliers

Domestic precision DAC suppliers often provide advantages in terms of local technical support, shorter lead times, and competitive pricing. Many Chinese manufacturers now offer products with specifications comparable to international alternatives while providing better supply chain security for domestic applications. However, some specialized high-end applications may still require international suppliers for the most advanced performance specifications or specific feature sets.

How important is temperature coefficient in precision DAC selection

Temperature coefficient specifications become critical in applications operating across wide temperature ranges or requiring long-term stability. A precision DAC with poor temperature performance may drift significantly over time or with environmental changes, compromising system accuracy. For high-precision applications, look for precision DAC devices with temperature coefficients better than 1 ppm/°C, while general industrial applications may accept specifications up to 10 ppm/°C depending on requirements.