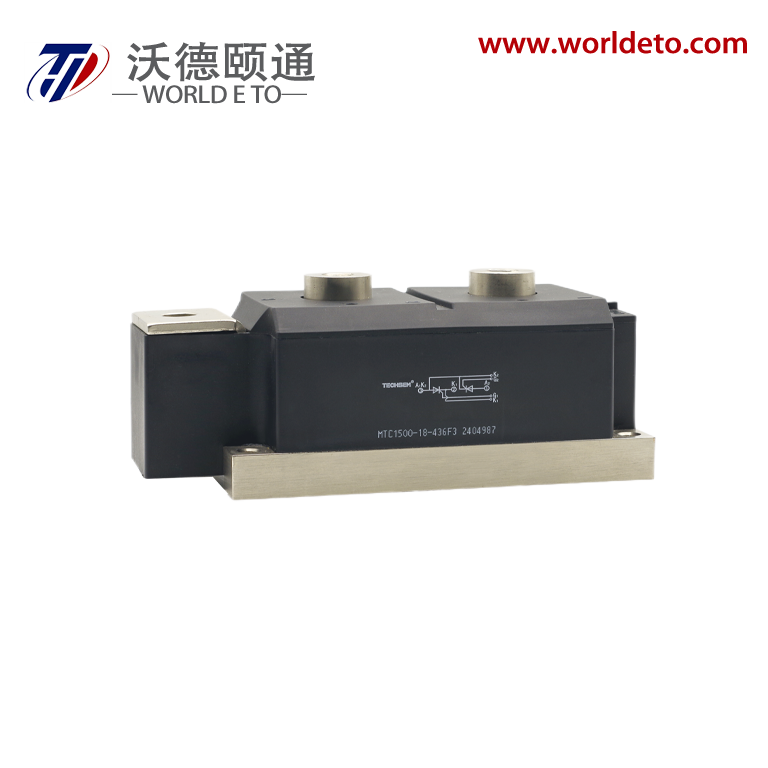

discrete transistor

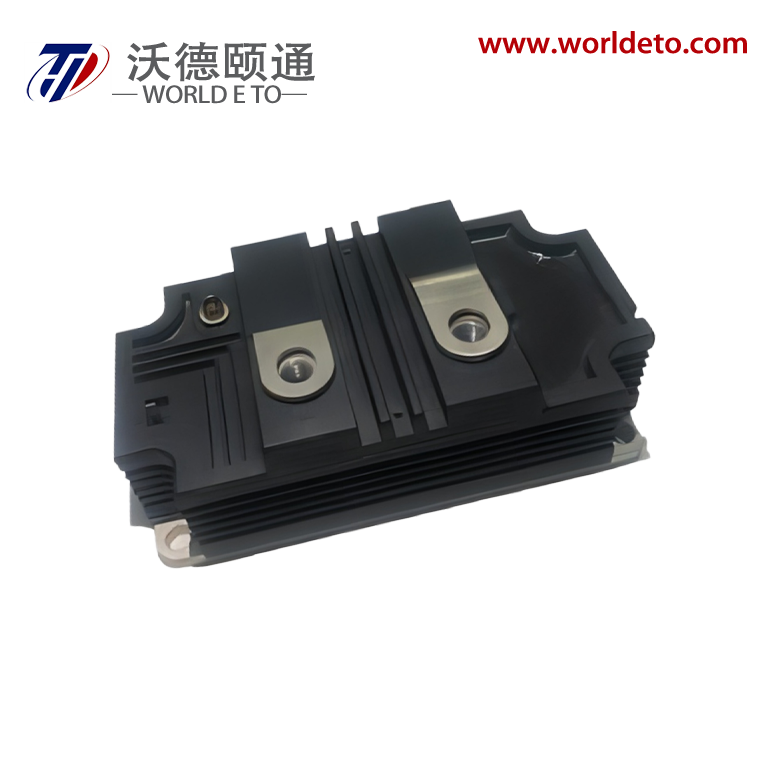

A discrete transistor represents a fundamental semiconductor component that operates as an individual electronic switching and amplification device. Unlike integrated circuits that combine multiple components on a single chip, the discrete transistor functions as a standalone unit, offering engineers and designers precise control over circuit performance. These semiconductor devices primarily serve three essential functions: signal amplification, electronic switching, and voltage regulation. The discrete transistor achieves these operations through the controlled movement of electrical current between three terminals, typically designated as the collector, base, and emitter in bipolar junction transistors, or drain, gate, and source in field-effect transistors. The technological architecture of discrete transistors incorporates advanced semiconductor materials, predominantly silicon and gallium arsenide, engineered to deliver superior electrical characteristics. Manufacturing processes employ sophisticated doping techniques that introduce specific impurities into the crystal structure, creating regions with distinct electrical properties. This precise material engineering enables discrete transistors to handle varying power levels, from low-signal applications requiring minimal current to high-power industrial systems demanding substantial electrical capacity. Modern discrete transistor designs incorporate enhanced thermal management features, including specialized packaging materials and heat dissipation structures that maintain optimal operating temperatures. Applications for discrete transistors span numerous industries and technological sectors. Power management systems rely on discrete transistors to regulate electrical flow in power supplies, motor controllers, and battery management circuits. Audio equipment manufacturers integrate discrete transistors into amplification stages, delivering superior sound quality through precise signal processing. Automotive electronics utilize discrete transistors in engine control units, lighting systems, and safety mechanisms. Telecommunications infrastructure depends on discrete transistors for signal processing, frequency conversion, and power amplification in base stations and communication equipment. Consumer electronics incorporate discrete transistors in switching power supplies, display drivers, and sensor interface circuits, enabling compact and efficient device operation across diverse applications.