Versatile Integration and Application Flexibility

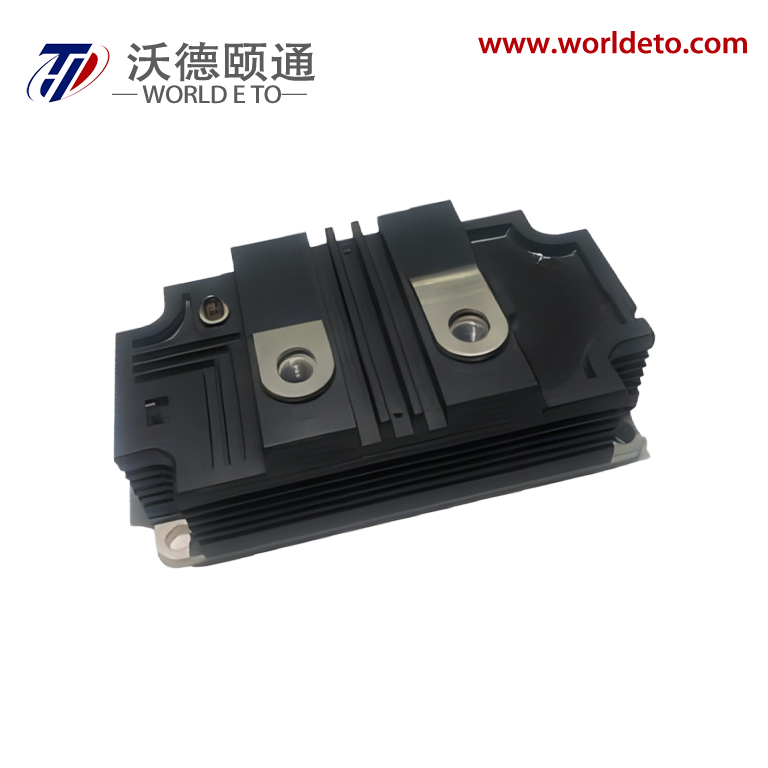

The transistor die offers remarkable versatility in terms of integration capabilities and application flexibility, making it suitable for an extensive range of electronic systems and industrial applications. This adaptability stems from standardized package formats and connection methods that facilitate seamless integration into existing circuit designs without requiring significant modifications or custom interface solutions. The modular nature of transistor die components allows engineers to easily scale systems up or down based on specific performance requirements or space constraints. Multiple voltage and current rating options ensure compatibility with diverse power supply configurations and load requirements across various application domains. The transistor die technology supports both analog and digital signal processing applications, providing engineers with the flexibility to implement complex control algorithms and signal conditioning functions within a single component solution. Advanced packaging options include surface-mount, through-hole, and chip-scale packages that accommodate different assembly methods and space requirements. The thermal interface design of transistor die components facilitates efficient heat dissipation through various cooling methods including natural convection, forced air cooling, and liquid cooling systems. This thermal flexibility enables optimal performance in applications ranging from compact consumer electronics to high-power industrial equipment. The transistor die supports parallel operation configurations that allow multiple devices to share load requirements, providing scalability for high-power applications while maintaining system reliability. Protection features including short-circuit protection, thermal shutdown, and safe operating area limits ensure safe operation across diverse operating conditions and load variations. The wide operating temperature range of quality transistor die components makes them suitable for automotive, aerospace, and industrial applications where environmental conditions can be extreme. Communication interface options enable integration with modern control systems and monitoring networks for advanced system management and diagnostic capabilities. The transistor die technology adapts to emerging application requirements through continuous development of new package formats, performance specifications, and integration features. This ongoing evolution ensures that transistor die components remain relevant and competitive as technology advances and new application opportunities emerge in evolving market segments.