Enhanced Thermal Management and Reliability

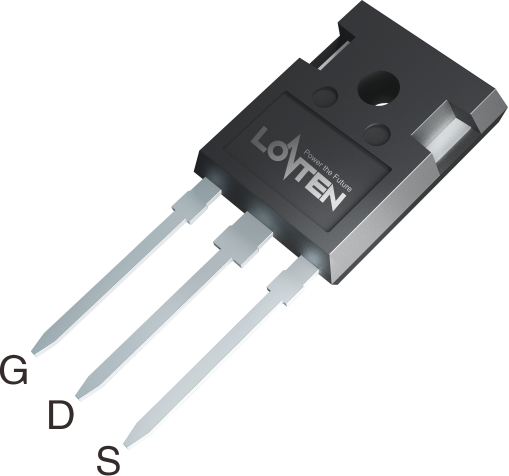

Enhanced thermal management capabilities distinguish fast recovery rectifiers as superior solutions for demanding applications where temperature control and long-term reliability are paramount concerns. The fundamental design improvements that enable fast switching also contribute to significantly reduced power dissipation compared to conventional rectifier technologies, creating a positive feedback effect that improves multiple performance parameters simultaneously. Lower power dissipation translates directly to reduced heat generation, which alleviates thermal stress on both the fast recovery rectifier itself and surrounding components within the system. This thermal advantage enables higher power density designs while maintaining safe operating temperatures, allowing engineers to pack more functionality into smaller enclosures without compromising reliability or requiring exotic cooling solutions. The improved thermal characteristics also support extended operating temperature ranges, with many fast recovery rectifiers capable of functioning reliably at junction temperatures exceeding 150 degrees Celsius, compared to lower limits for standard rectifiers. This temperature tolerance proves invaluable in automotive, aerospace, and industrial applications where ambient temperatures can vary dramatically or where cooling airflow may be restricted. The enhanced reliability stems from multiple factors beyond simple temperature reduction, including improved semiconductor crystal structure, optimized metallization systems, and advanced packaging technologies that resist thermal cycling stress. These improvements result in significantly longer operational lifespans, with many fast recovery rectifiers demonstrating mean time between failure rates exceeding 500,000 hours under normal operating conditions. The reliability improvements translate to reduced maintenance costs, fewer unexpected system failures, and improved customer satisfaction in critical applications. Furthermore, the stable thermal performance enables more predictable system behavior across temperature variations, simplifying design validation and reducing the need for extensive temperature compensation circuits. Manufacturing processes for fast recovery rectifiers often incorporate advanced quality control measures and burn-in procedures that identify potential early failures before products reach customers, further enhancing field reliability. The combination of inherent thermal advantages and rigorous manufacturing standards creates rectifier solutions that consistently deliver dependable performance in challenging environments where conventional devices might fail prematurely.