Exceptional Reliability and Robust Design

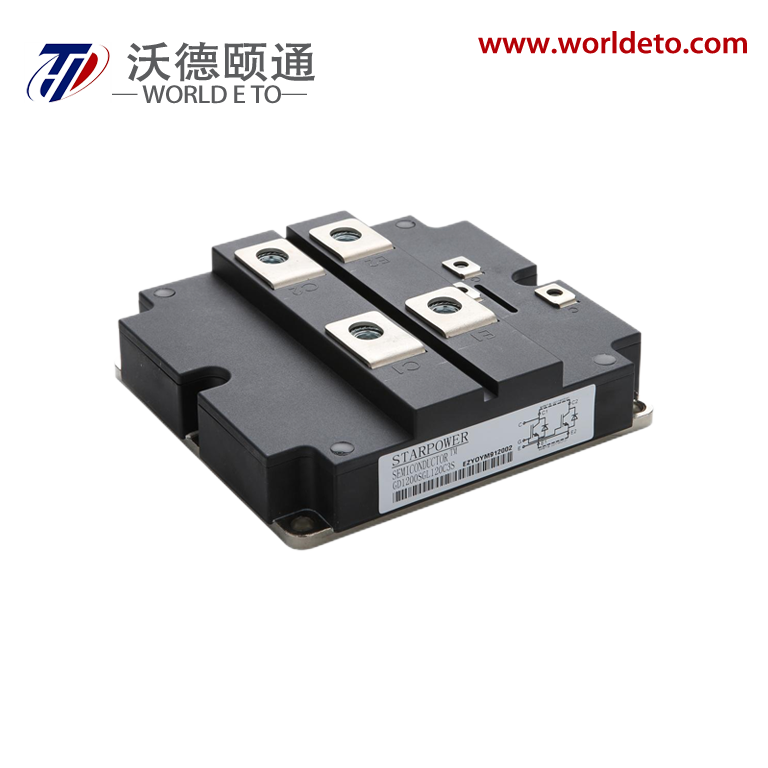

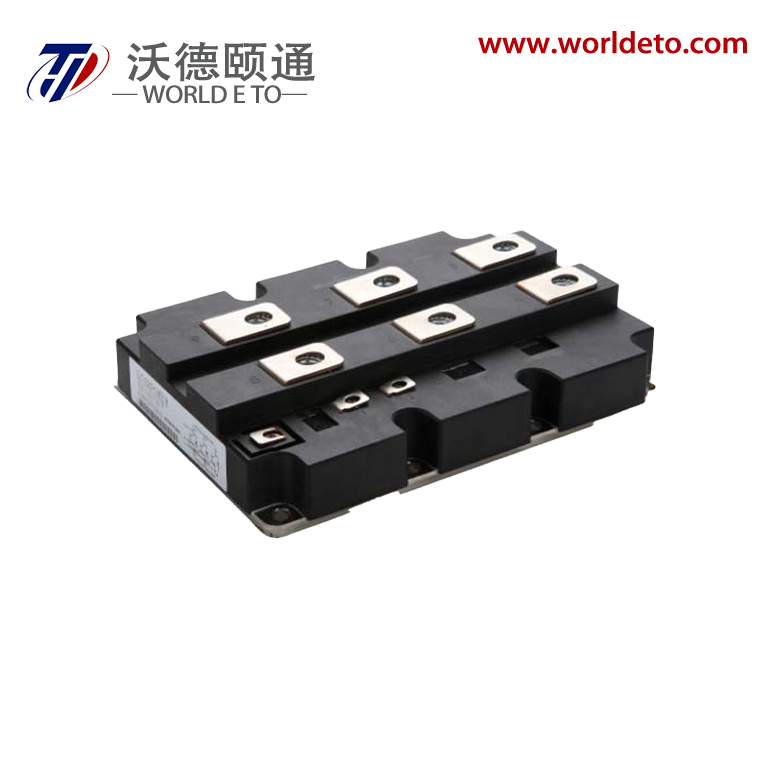

The high power IGBT stands out in the semiconductor industry for its exceptional reliability and robust design characteristics that ensure consistent performance in the most demanding industrial environments. Engineering teams specifically design these devices to withstand extreme operating conditions including high temperatures, voltage spikes, mechanical stress, and electromagnetic interference that would compromise lesser power semiconductors. The robust package construction of high power IGBT modules incorporates advanced materials and manufacturing techniques that provide superior protection against environmental factors while maintaining optimal thermal performance. Specialized wire bonding techniques, high-grade ceramic substrates, and advanced encapsulation materials work together to create a package that resists thermal cycling stress, humidity, and mechanical vibrations commonly encountered in industrial applications. The high power IGBT features built-in protection mechanisms that detect and respond to fault conditions before damage occurs, including sophisticated overcurrent detection circuits that can shut down the device within microseconds of detecting dangerous current levels. Temperature monitoring capabilities integrated into high power IGBT designs provide real-time feedback about device operating conditions, enabling predictive maintenance strategies that prevent unexpected failures and extend equipment lifespan. The gate structure of a high power IGBT utilizes advanced insulation technology that provides excellent immunity to voltage transients and electromagnetic interference, ensuring reliable switching operation even in electrically noisy environments. Quality assurance processes for high power IGBT manufacturing include extensive testing protocols that verify device performance under accelerated aging conditions, thermal cycling, and electrical stress testing that simulates years of operation in compressed timeframes. This rigorous testing approach ensures that high power IGBT devices meet stringent reliability standards required for critical applications in industrial automation, renewable energy systems, and transportation equipment where unexpected failures could result in significant economic losses or safety hazards.