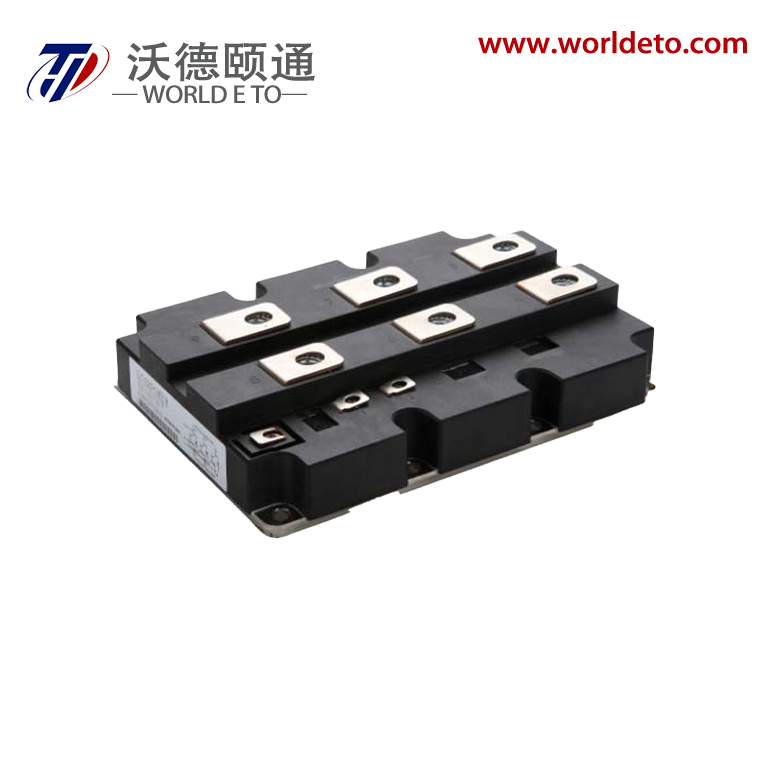

igbt rectifier

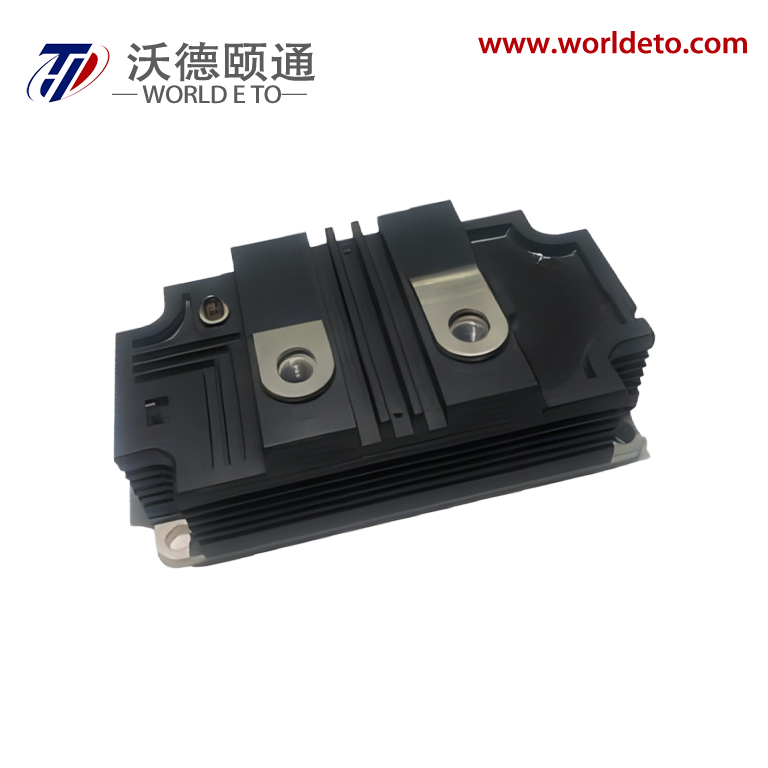

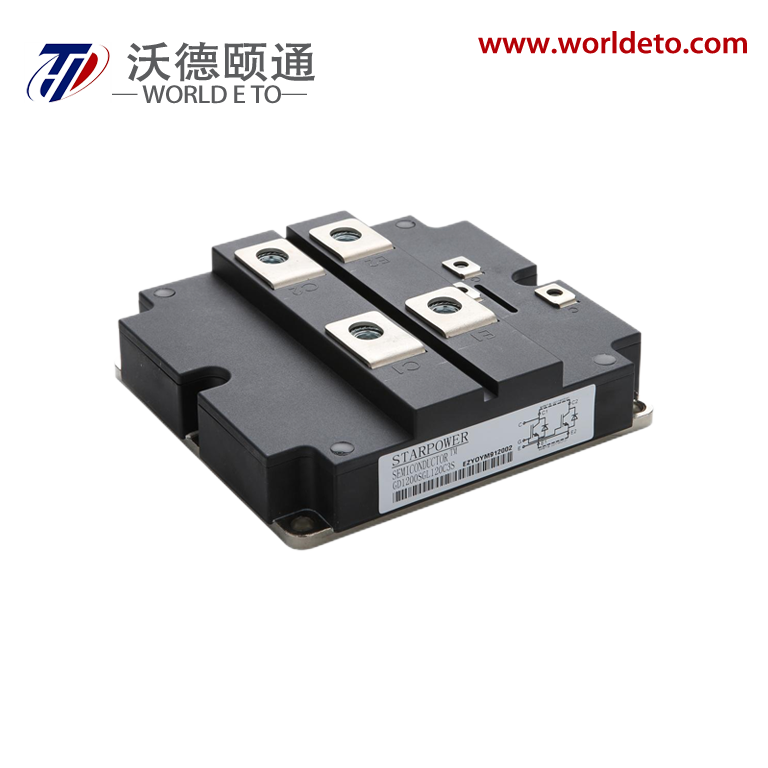

An IGBT rectifier represents a sophisticated power electronics device that combines Insulated Gate Bipolar Transistor technology with rectification capabilities to deliver superior electrical power conversion solutions. This advanced system transforms alternating current (AC) input into direct current (DC) output while maintaining exceptional efficiency and control precision. The IGBT rectifier operates by utilizing the unique characteristics of IGBT switches, which merge the high-speed switching capabilities of MOSFETs with the high current handling capacity of bipolar transistors. This hybrid approach enables the device to manage substantial power loads while maintaining rapid response times and minimal switching losses. The primary function of an IGBT rectifier involves controlled rectification, where the switching elements actively regulate the conversion process rather than relying on passive diode rectification. This active control mechanism allows for power factor correction, harmonic reduction, and bidirectional power flow capabilities. The technological architecture incorporates pulse width modulation (PWM) control strategies that optimize switching patterns to achieve desired output characteristics. Modern IGBT rectifiers feature sophisticated gate drive circuits that ensure proper switching timing and protection against overcurrent, overvoltage, and thermal stress conditions. These devices excel in applications requiring precise voltage regulation, high power density, and excellent dynamic response characteristics. Industrial applications include variable frequency drives, renewable energy systems, electric vehicle charging stations, and uninterruptible power supplies. The IGBT rectifier's ability to operate across wide voltage and current ranges makes it suitable for both low-power consumer electronics and high-power industrial installations. Advanced control algorithms enable these systems to adapt to varying load conditions while maintaining optimal efficiency levels throughout the operating range.