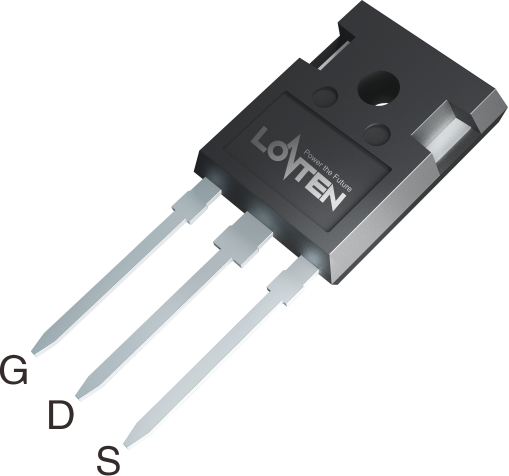

high voltage transistor

The high voltage transistor represents a crucial semiconductor device engineered to handle substantial electrical voltages while maintaining precise control and switching capabilities. These specialized components operate effectively at voltage levels significantly higher than standard transistors, typically ranging from hundreds to thousands of volts. The primary function of a high voltage transistor involves amplifying electrical signals and controlling current flow in demanding applications where conventional transistors would fail or become unreliable. The technological foundation of high voltage transistors relies on advanced semiconductor materials and innovative design structures that enable superior voltage blocking capabilities. These devices utilize wider bandgap materials such as silicon carbide or gallium nitride, which provide enhanced breakdown voltage characteristics compared to traditional silicon-based components. The internal architecture features carefully engineered junction designs, optimized gate structures, and specialized packaging that collectively enable safe operation under extreme electrical stress. Modern high voltage transistor technology incorporates sophisticated manufacturing processes that ensure consistent performance and reliability. The fabrication involves precise doping profiles, advanced lithography techniques, and stringent quality control measures to achieve the necessary electrical specifications. These transistors demonstrate exceptional switching speeds, low on-resistance characteristics, and robust thermal management capabilities. Applications for high voltage transistors span numerous industries and systems. Power supply circuits extensively utilize these components for efficient voltage conversion and regulation. Motor drive systems benefit from their ability to control high-power electric motors with precision and reliability. Automotive electronics increasingly depend on high voltage transistors for electric vehicle powertrains, hybrid systems, and advanced driver assistance features. Industrial automation equipment relies on these devices for controlling heavy machinery and processing equipment. Renewable energy systems, including solar inverters and wind power converters, extensively employ high voltage transistors to manage power conversion efficiently. Medical equipment utilizes these components in imaging systems, therapeutic devices, and diagnostic instruments where high voltage operation is essential for proper functionality.