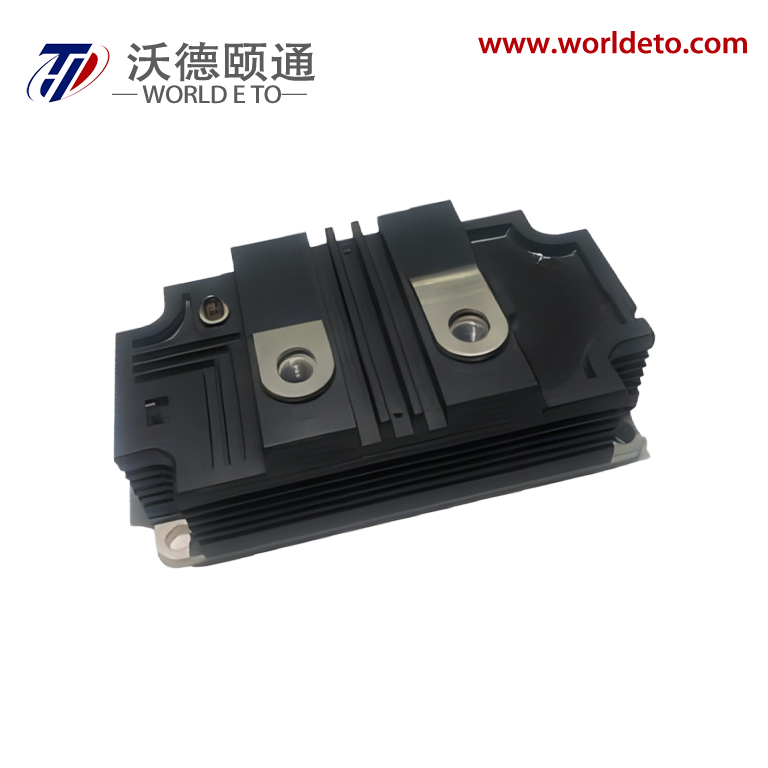

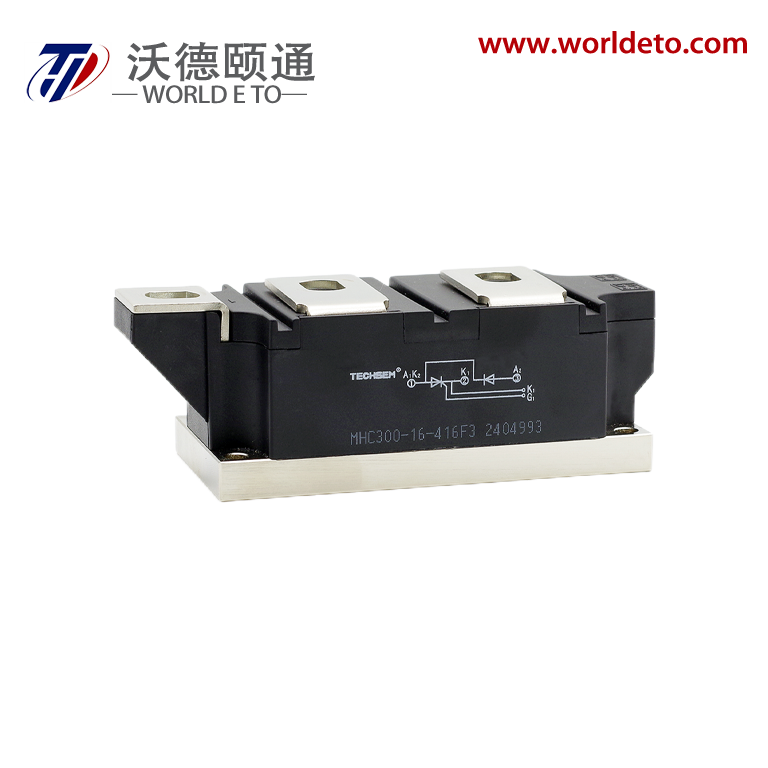

industrial rectifier

An industrial rectifier is a critical power conversion device designed to transform alternating current (AC) into direct current (DC) for heavy-duty industrial applications. This essential equipment serves as the backbone of numerous manufacturing processes, providing stable and reliable DC power to support various industrial operations. The industrial rectifier operates through sophisticated semiconductor technology, typically utilizing silicon diodes, thyristors, or advanced IGBT modules to achieve efficient power conversion. These devices are engineered to handle substantial power loads, often ranging from several kilowatts to multiple megawatts, making them indispensable for large-scale industrial facilities. The primary function of an industrial rectifier extends beyond simple AC to DC conversion, incorporating advanced control systems that regulate output voltage, current, and power factor correction. Modern industrial rectifiers feature microprocessor-based control units that enable precise monitoring and adjustment of electrical parameters, ensuring optimal performance across varying load conditions. The technological framework includes robust filtering systems that minimize harmonic distortion and electromagnetic interference, protecting sensitive equipment downstream. Heat management represents another crucial aspect, with industrial rectifiers incorporating sophisticated cooling systems including forced air circulation, liquid cooling, or hybrid cooling solutions to maintain operational temperatures within safe limits. These power conversion systems find extensive applications across diverse industrial sectors including electroplating, aluminum smelting, steel production, chemical processing, telecommunications, data centers, and renewable energy systems. In electrochemical industries, industrial rectifiers provide the precise DC power required for metal refining and electroplating processes. The mining sector relies on these devices for ore processing and metal extraction operations. Additionally, industrial rectifiers play a vital role in supporting uninterruptible power supply systems, ensuring continuous operation of critical infrastructure during power outages or voltage fluctuations.