Enhanced Reliability and Robust Construction

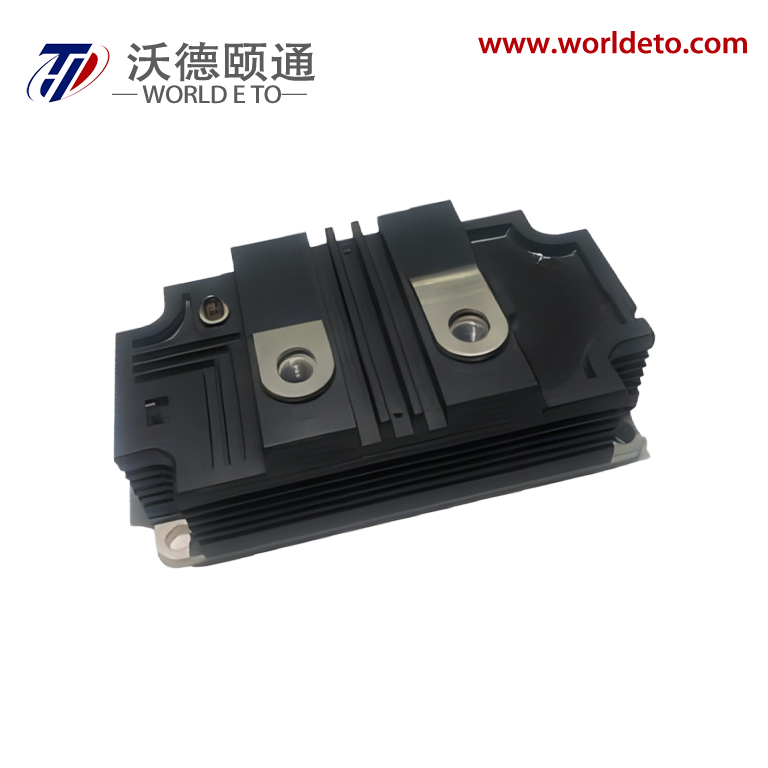

The IGBT thyristor incorporates cutting-edge materials science and manufacturing techniques that deliver exceptional reliability and longevity in demanding applications. Advanced silicon carbide technology and proprietary packaging methods create devices capable of withstanding extreme operating conditions while maintaining consistent performance over extended periods. The robust construction features reinforced wire bonds, optimized thermal interfaces, and protective coatings that resist environmental stressors including humidity, vibration, and temperature fluctuations. Comprehensive testing procedures ensure each IGBT thyristor meets stringent quality standards before leaving the factory, with devices undergoing thermal cycling, electrical stress testing, and accelerated aging processes. This rigorous quality assurance results in failure rates below 0.01 percent under normal operating conditions, providing users with confidence in system reliability. The enhanced reliability reduces maintenance costs and eliminates unexpected downtime that can cost industrial operations thousands of dollars per hour. Built-in protection features include overcurrent detection, thermal shutdown, and short-circuit protection that safeguard both the device and connected equipment. The robust design allows operation in temperature ranges from negative 40 to positive 150 degrees Celsius, making the IGBT thyristor suitable for harsh industrial environments including steel mills, mining operations, and outdoor renewable energy installations. Long-term stability testing demonstrates consistent performance characteristics over 100,000 operating hours, ensuring reliable operation throughout the device's extended service life. Users benefit from predictable maintenance schedules and reduced spare parts inventory requirements. The enhanced reliability enables deployment in critical applications where failure is not acceptable, including medical equipment, emergency power systems, and safety-critical industrial processes. This reliability advantage translates to improved customer satisfaction, reduced warranty claims, and enhanced reputation for equipment manufacturers who incorporate IGBT thyristor technology into their products.