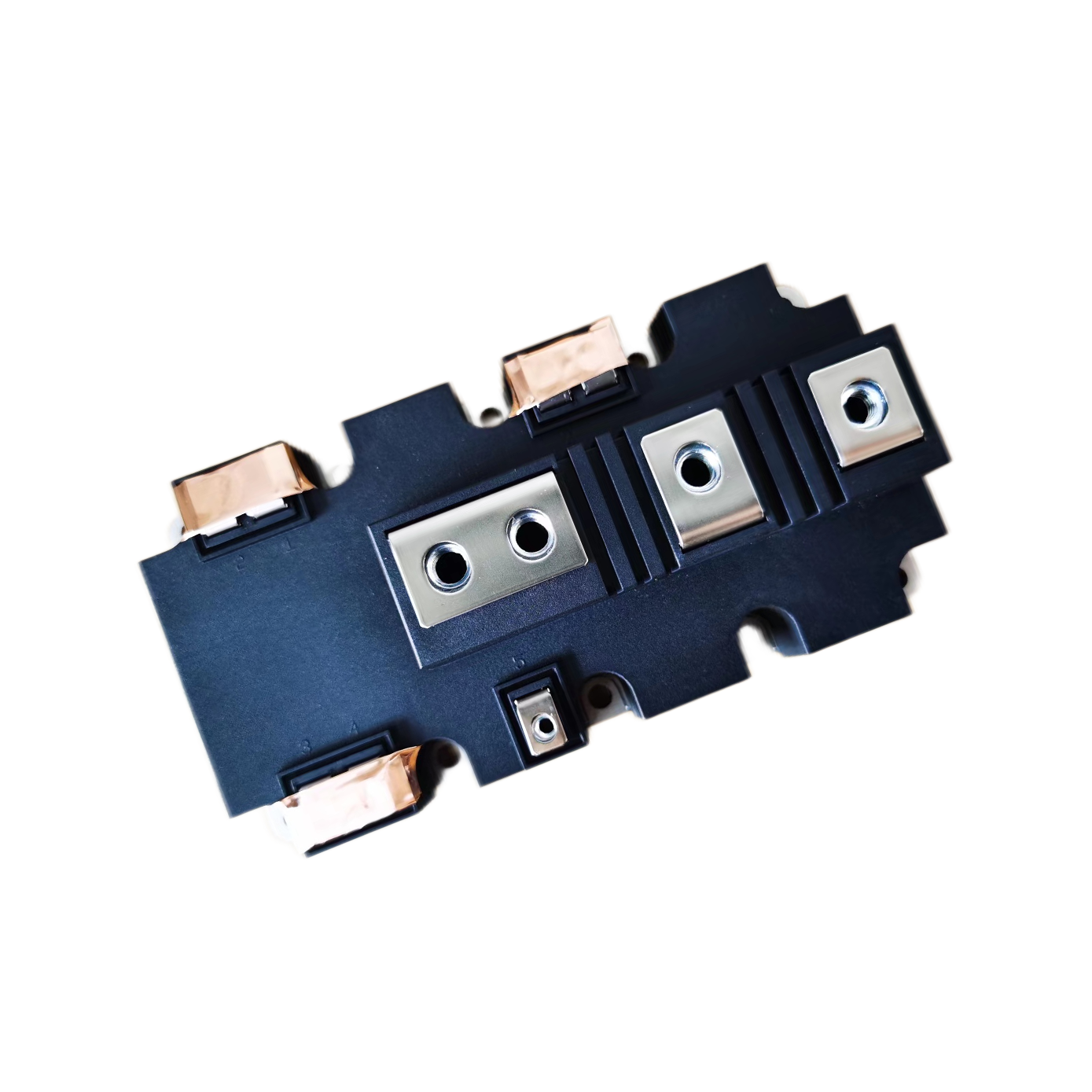

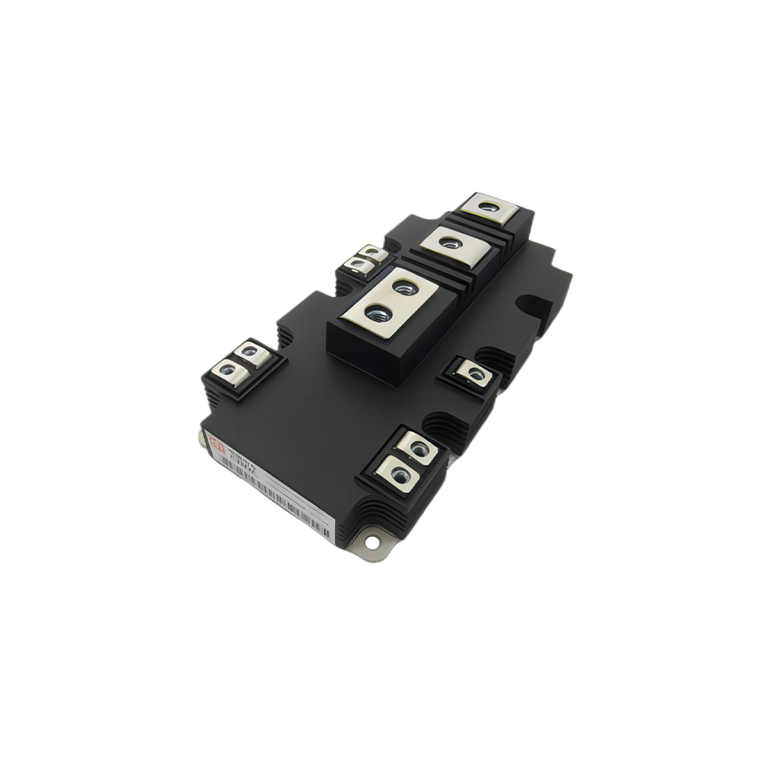

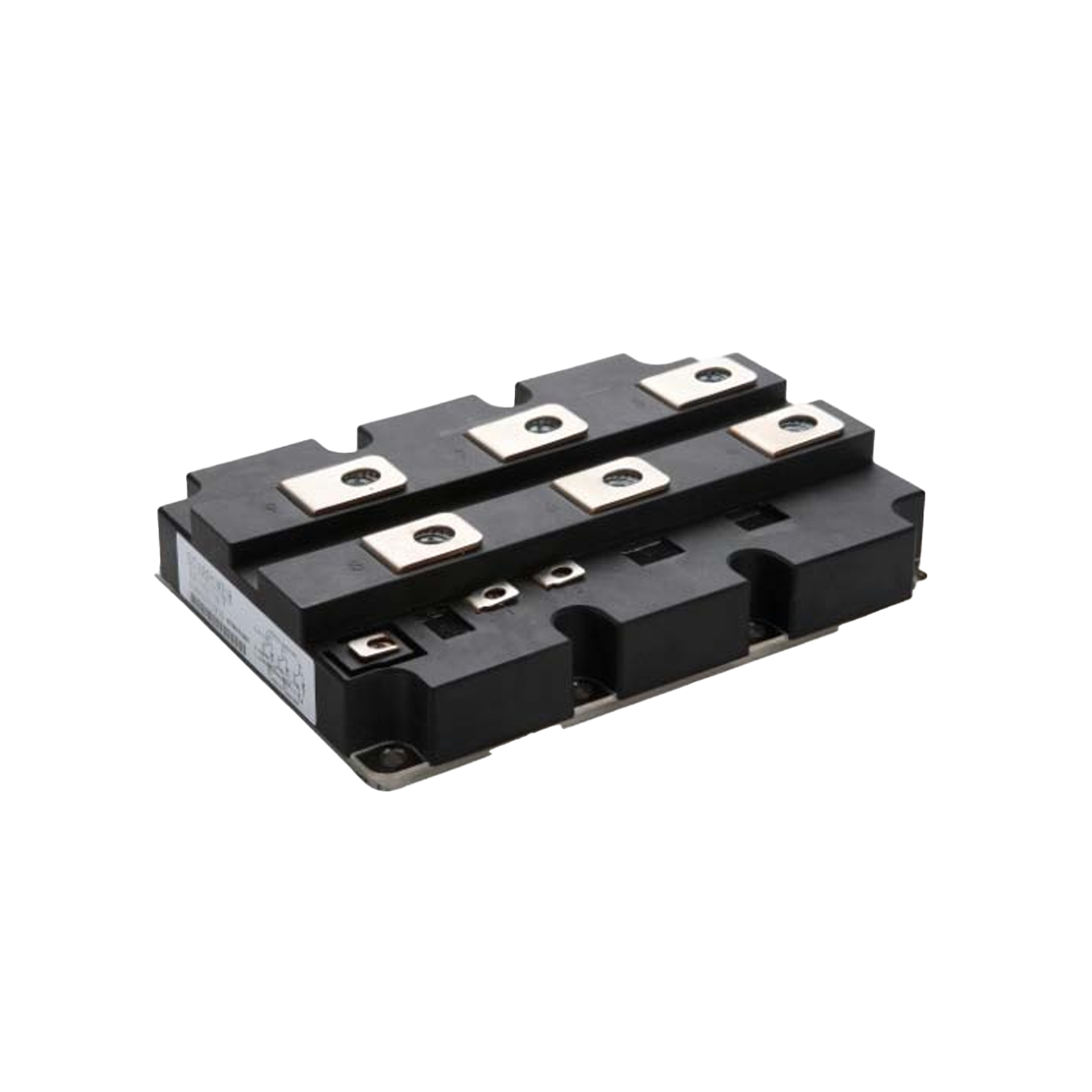

fast thyristor

The fast thyristor represents a revolutionary advancement in semiconductor switching technology, designed to deliver exceptional performance in high-frequency power electronics applications. This sophisticated device combines the robust switching capabilities of traditional thyristors with enhanced speed characteristics that enable rapid turn-on and turn-off operations. Unlike conventional thyristors that may require extended commutation times, the fast thyristor incorporates advanced semiconductor engineering to achieve switching speeds measured in microseconds rather than milliseconds. The main functions of this device center around precise power control, voltage regulation, and current switching in demanding electrical systems. Its primary role involves managing electrical power flow while maintaining excellent thermal stability and voltage handling capabilities. The fast thyristor operates by using gate-controlled switching mechanisms that respond quickly to control signals, allowing for dynamic power management in real-time applications. Technological features include optimized silicon wafer construction with specially designed junction geometries that minimize switching losses and reduce electromagnetic interference. The device incorporates advanced doping profiles that enhance carrier mobility and reduce recovery times significantly. Modern fast thyristor designs feature integrated protection circuits, temperature monitoring capabilities, and enhanced gate sensitivity for improved control precision. These devices typically handle voltage ratings from several hundred volts to multiple kilovolts, with current capabilities ranging from amperes to thousands of amperes depending on the specific model. Applications span across industrial motor drives, renewable energy conversion systems, high-frequency inverters, welding equipment, and power transmission systems. The fast thyristor proves particularly valuable in applications requiring precise timing control, such as phase-controlled rectifiers, cycloconverters, and variable frequency drives. Its reliability and performance characteristics make it essential for modern power electronics where efficiency and speed are critical requirements.