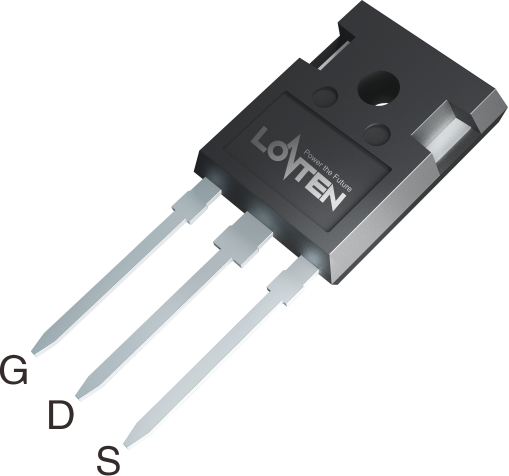

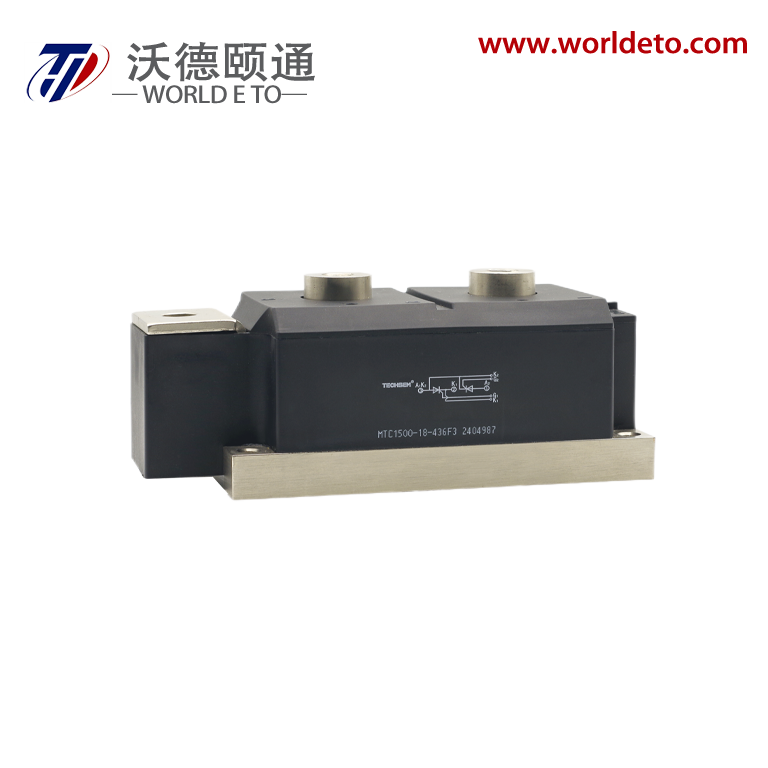

transistor ic

The transistor ic represents a revolutionary advancement in semiconductor technology, combining multiple transistors and electronic components into a single integrated circuit package. This sophisticated electronic component serves as the fundamental building block for modern digital and analog systems, enabling complex signal processing, amplification, and switching operations within compact form factors. The transistor ic operates by controlling electrical current flow through semiconductor materials, typically silicon or gallium arsenide, allowing precise manipulation of electronic signals across various applications. These integrated circuits incorporate numerous transistor elements, resistors, capacitors, and interconnections fabricated on a single substrate using advanced photolithographic processes. The primary functions of transistor ic devices include signal amplification, where weak input signals receive substantial power boost for transmission or processing purposes. Additionally, these components excel at digital switching operations, rapidly transitioning between conducting and non-conducting states to represent binary data in computational systems. The technological features of transistor ic designs encompass miniaturization capabilities that pack millions or billions of transistors into microscopic spaces, enabling powerful processing capabilities within portable devices. Modern fabrication techniques achieve feature sizes measured in nanometers, allowing unprecedented component density while maintaining reliable performance characteristics. Temperature stability represents another crucial technological aspect, with transistor ic components engineered to operate effectively across wide temperature ranges without performance degradation. Power efficiency optimization ensures minimal energy consumption during operation, making these components ideal for battery-powered applications and environmentally conscious designs. The applications for transistor ic technology span virtually every electronic device category, from smartphones and computers to automotive control systems and industrial automation equipment. Consumer electronics rely heavily on transistor ic components for processing audio, video, and data signals with exceptional accuracy and speed. Medical devices incorporate these integrated circuits for patient monitoring, diagnostic equipment, and therapeutic systems requiring precise control and reliable operation.