three phase soft starter

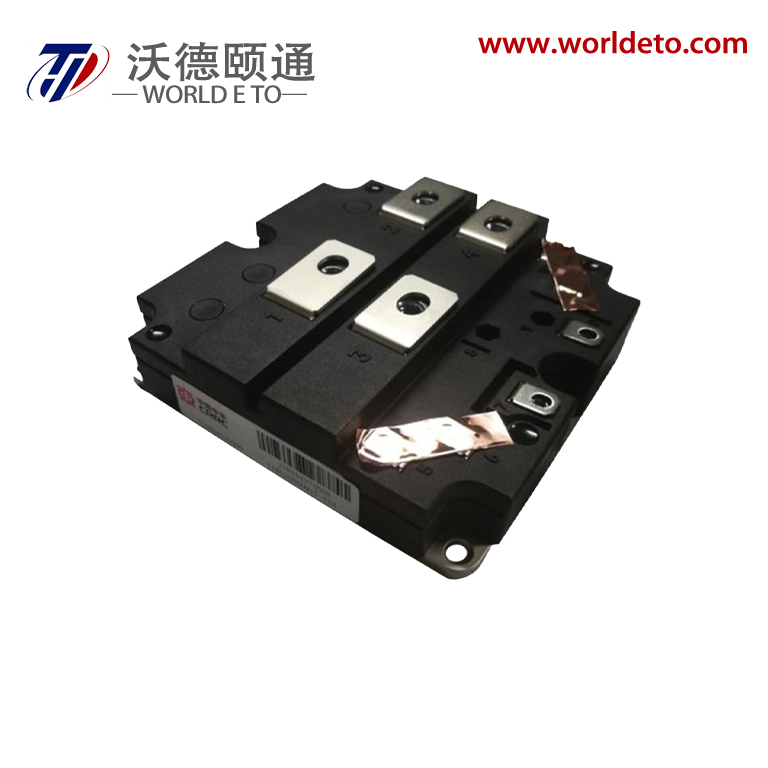

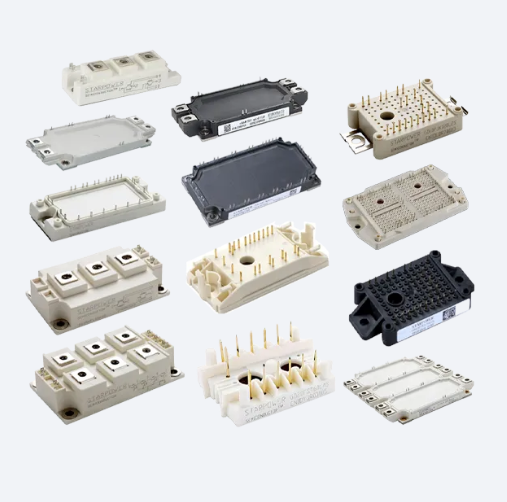

A three phase soft starter is an advanced electronic device designed to control the acceleration and deceleration of three phase electric motors, providing a smooth and controlled start-up process. This sophisticated piece of equipment effectively manages the voltage supplied to the motor during startup, gradually increasing it from an initial reduced level to full voltage, thereby eliminating mechanical stress and reducing electrical strain on both the motor and connected equipment. The soft starter incorporates solid-state power electronics, typically thyristors or SCRs, in each phase of the three phase power supply. By controlling these components, it effectively manages current and torque during motor startup, significantly reducing mechanical shock, excessive current draw, and voltage dips in the power supply system. The device offers various starting modes, including voltage ramp, current limit, and torque control, allowing users to select the most appropriate starting method for their specific application. Applications of three phase soft starters span across numerous industries, including manufacturing, mining, water treatment, and HVAC systems. They are particularly valuable in applications involving conveyor belts, pumps, fans, and compressors where smooth starting and stopping are essential for operational efficiency and equipment longevity. Modern soft starters often include advanced features such as motor protection, fault diagnostics, and communication capabilities, making them an integral part of contemporary industrial automation systems.