The Role of IGBT Modules in Modern Motor Drives

Fundamental Principles of IGBT Technology

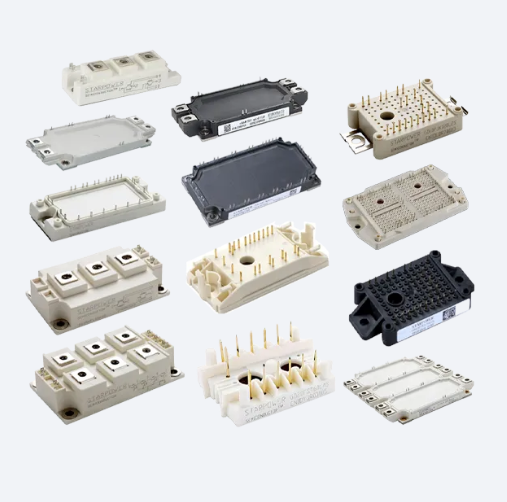

IGBT modules, also known as Insulated Gate Bipolar Transistors, play a vital role in various switching applications by combining advantages from both BJTs and MOSFET technologies. These components handle significant voltages and currents while keeping power loss to a minimum, which makes them particularly suitable for precision motor drives where performance matters most. What sets IGBTs apart is how they bring together the straightforward operation of MOSFETs with the strong current handling capability and low saturation voltage found in BJTs. This combination results in devices that waste far less energy during operation. When looking at IGBT performance, gate control timing becomes critical since it directly affects how fast the transistor can switch states and manage energy throughout different applications across industries like automotive and industrial automation.

Why Motor Drives Rely on IGBT Modules

IGBT modules play a key role in making modern motor drives both reliable and efficient, especially since they're essential for pulse width modulation (PWM) which controls motor speed and torque precisely. We've seen these modules become standard equipment in many different industries where motor drive systems need optimization. Take automotive manufacturing and heavy industry as examples. These fields depend on IGBT modules because they offer superior performance characteristics that boost overall operations. Industry research backs this up too, indicating that companies increasingly turn to energy efficient solutions like IGBTs to meet their performance targets while keeping costs under control.

Precision Engineering in IGBT Module Design

Thermal Management Strategies for Stability

Keeping things cool matters a lot when it comes to IGBT modules used in those big power systems everyone's installing nowadays. When temperatures get too hot, these modules start acting up and don't last as long as they should. Most folks tackle this problem using heatsinks, sometimes go all out with liquid cooling systems, or slap on some fancy thermal interface stuff between components. A recent paper from the Journal of Power Electronics showed something interesting though. They found that adding better heat sinks along with those phase change materials actually makes a noticeable difference in how well IGBTs handle heat stress. The result? Systems run smoother and waste less energy overall. Just ask any technician who's had to replace modules prematurely because someone skimped on the cooling solution. Thermal management isn't just nice to have it's basically table stakes in modern power electronics design.

Optimizing Switching Speeds for Control Accuracy

Getting the switching speeds right for IGBT modules makes all the difference when it comes to controlling motors precisely. This matters a lot in systems where quick responses and good efficiency are needed. When these modules switch faster, they give better control over motor operation. However there's a catch too fast switching creates more heat and wastes energy. Some tests have shown cutting down on switching time by around 20 percent leads to much better performance during sudden changes in load, while not making the energy loss jump up as much as one might expect. New control methods such as adaptive PWM approaches help out here too. These smart algorithms tweak parameters on the fly depending on what's happening in the system at any given moment. The bottom line? Manufacturers who focus on these kinds of optimizations get the best of both worlds speed and efficiency without breaking a sweat.

Material Innovations: Silicon vs. SiC/GaN

The traditional silicon IGBT is now facing serious competition from newer materials like Silicon Carbide (SiC) and Gallium Nitride (GaN). These wide bandgap alternatives bring real improvements across several key areas. They can handle much higher voltages, operate at extreme temperatures, and deliver better overall efficiency. Take SiC specifically it allows for much faster switching frequencies, which means power systems can be made smaller while needing far less cooling infrastructure. Looking at current market movements, we're seeing a clear migration toward these materials in industries such as electric vehicles and solar power generation. Industry analysts predict that within five years, SiC and GaN could capture over 40% of the IGBT market share. This isn't just theoretical either manufacturers are already redesigning their product lines to accommodate these new materials, fundamentally changing what engineers expect from modern power electronics solutions.

Performance Advantages in Motor Drive Systems

Enhancing Energy Efficiency in Industrial Automation

IGBT modules play a major role in making industrial automation systems more energy efficient. They help cut down on power usage in motor drives because they control electricity better than older technologies. Take manufacturing plants for example many have seen real reductions in their energy bills after switching to IGBT based systems. Some factories report cutting energy waste by over 30% just from upgrading their drive systems. A prime example is regenerative braking technology where machines actually capture energy when they slow down and send it back into the grid. This kind of energy回收 isn't just good for the bottom line either it helps reduce carbon footprints across entire production lines. Companies adopting these systems often find themselves saving money while meeting stricter environmental regulations at the same time.

High-Torque Control for Electric Vehicle Powertrains

IGBT modules are really important for controlling high torque in electric vehicle powertrains, giving both precision and good efficiency. These modules help regulate electrical currents and voltages so EVs can deliver their torque properly, which matters a lot when it comes to acceleration and overall driving experience. Take Tesla and Nissan for instance – they've incorporated IGBT tech into their designs, which helps explain why these cars handle corners so well and respond quickly off the line. But there are still some hurdles facing the industry. Managing heat remains a big issue, plus manufacturers need to find ways to incorporate new materials that will boost efficiency even further. We're seeing all sorts of developments in torque control systems lately, with companies working hard to build stronger, greener powertrains that can withstand real world conditions while maintaining that signature electric vehicle performance.

Key Applications Across Industries

EV Motor Drives: Case Studies in Automotive Innovation

The introduction of IGBT modules into electric vehicle motor systems marks a major turning point in how cars work today. Take the Tesla Model S for example it actually uses these modules which helped boost its speed while using less electricity overall. What makes IGBTs so special is their ability to fine tune torque delivery, something drivers notice immediately when they get behind the wheel. Real world tests showed cars could go farther between charges and handle power much better than older models without them. Looking ahead, as car manufacturers keep pushing boundaries in design and function, components like IGBT modules will play a crucial part in making electric vehicles not just environmentally friendly but also practical for everyday use across different markets around the globe.

Renewable Energy Integration: Wind and Solar Systems

IGBT modules are becoming increasingly important for connecting renewable energy sources to the grid, making the whole system more stable and reliable. They're used extensively in wind farms and solar panel arrays because they help convert electricity more efficiently from one form to another. Some real world tests have shown that when facilities install IGBT technology, their overall efficiency jumps by around 20%. That's pretty impressive considering renewable energy markets worldwide are growing at about 6.1% each year according to recent data. With more people looking for ways to make clean energy work better, these semiconductor components are proving essential for meeting sustainability targets while keeping power grids dependable and capable of handling higher loads as we move toward greener alternatives.

Industrial Motor Control for Manufacturing

IGBT modules play a key role in modern manufacturing and robotics when it comes to controlling industrial motors effectively. These components allow for much better precision during operations which means less time spent fixing breakdowns and overall higher productivity levels. Some stats from the field show that after installing IGBT technology, many plants saw around 15 percent fewer stoppages compared to before. We see this working well in practice across various equipment like CNC machining centers and robotic assembly lines where consistent performance matters most. The improved control they offer cuts down on those annoying operational hiccups that slow things down. As factories continue moving toward smart automation under Industry 4.0 concepts, having reliable IGBT modules becomes increasingly important for maintaining both production speed and product quality standards.

Future Trends in IGBT Module Development

Smart Modules with Integrated Monitoring

Smart tech integration in IGBT modules is changing how we approach power management today, mainly because it allows real time monitoring plus detailed data analysis on system performance. These modules do more than just boost efficiency they actually help predict when maintenance might be needed based on what's happening inside those power systems right now. Take a look at what Infineon Technologies and Renesas Electronics have been doing lately both companies are adding intelligent features to their IGBT products which work really well with modern smart grid infrastructure and vehicle electrical systems. When businesses switch to these newer module designs, they see fewer surprise breakdowns and machines that last longer overall. Plus there's an added bonus of better energy control across operations that translates into real money savings over years instead of months.

Wide Bandgap Semiconductors: The Next Frontier

The semiconductor world is seeing something pretty exciting these days with wide bandgap materials like Silicon Carbide (SiC) and Gallium Nitride (GaN). These new materials stand out because they can actually make IGBT technology work better than ever before. They offer improved efficiency rates and much quicker switching times when compared to those old fashioned silicon based IGBT modules we've been using for years. Industry insiders think there will be a big push towards adopting this wide bandgap tech in coming years. Why? Because the market needs better power electronics across several key areas including solar power installations, EV charging stations, and factory automation systems where reliability matters most. According to recent market analysis reports, both SiC and GaN seem ready to take over a large portion of the market share. Their ability to perform well even under harsh operating conditions without sacrificing too much energy makes them particularly attractive options for manufacturers looking to upgrade their equipment.

FAQ

What are IGBT modules?

IGBT modules or Insulated Gate Bipolar Transistors are devices used in electronic systems for efficient switching, blending the advantages of BJTs and MOSFETs.

Why are IGBT modules important in motor drives?

IGBT modules are essential in motor drives for their role in pulse-width modulation which ensures precise motor speed and torque control, boosting overall system performance and energy efficiency.

How do IGBT modules enhance energy efficiency?

IGBT modules improve energy efficiency by reducing energy consumption in motor drives, facilitating efficient electrical control, and enabling technologies like regenerative braking.

What are SiC and GaN materials?

Silicon Carbide (SiC) and Gallium Nitride (GaN) are wide bandgap semiconductors offering high voltage capacity, efficient performance, and better thermal management than traditional silicon IGBTs.

How are smart IGBT modules different?

Smart IGBT modules incorporate real-time monitoring and data analysis capabilities, enhancing operational efficiency and predictive maintenance for improved system reliability.