6.6 kv soft starter

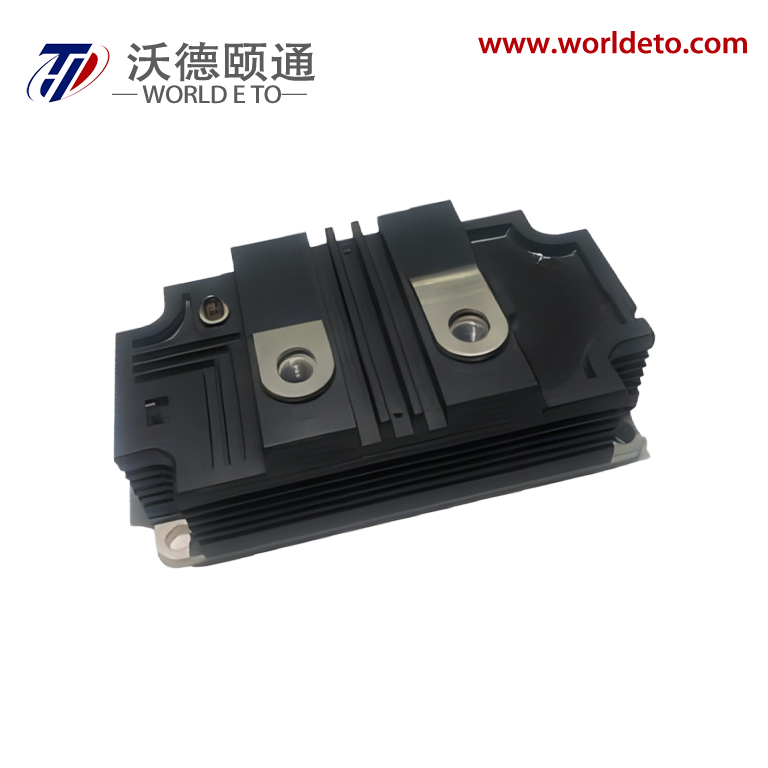

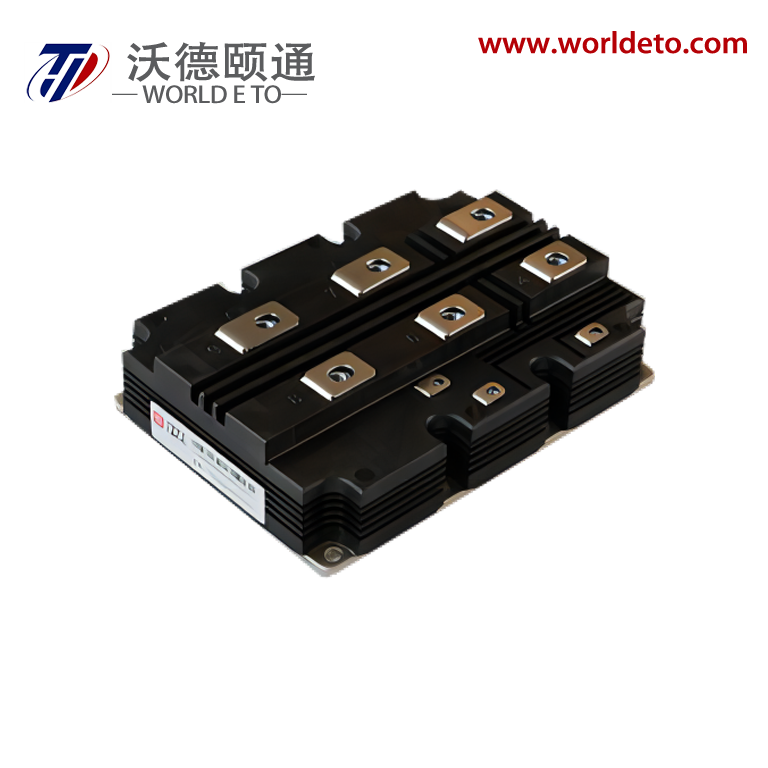

The 6.6 kV soft starter represents a sophisticated power electronic device engineered specifically for high voltage motor applications in industrial settings. This advanced starting system provides controlled acceleration and deceleration of medium voltage motors, effectively managing voltage supply during the critical startup phase. The device operates by gradually increasing the voltage to the motor, significantly reducing mechanical stress on the drive train and electrical stress on the power network. With its state of the art semiconductor technology, the 6.6 kV soft starter incorporates advanced microprocessor control systems that continuously monitor and adjust starting parameters. The system features comprehensive motor protection functions, including overcurrent, phase imbalance, and ground fault protection. It excels in applications such as pumps, fans, compressors, and conveyor systems where smooth starting and stopping are essential. The soft starter's robust design ensures reliable operation in harsh industrial environments, while its sophisticated control algorithms optimize energy consumption during motor startup. This technology proves particularly valuable in facilities where power supply limitations or mechanical stress concerns necessitate controlled motor starting.