IGBT Modules in Electric Welding Machines: How They Enhance Efficiency and Stabilityâ

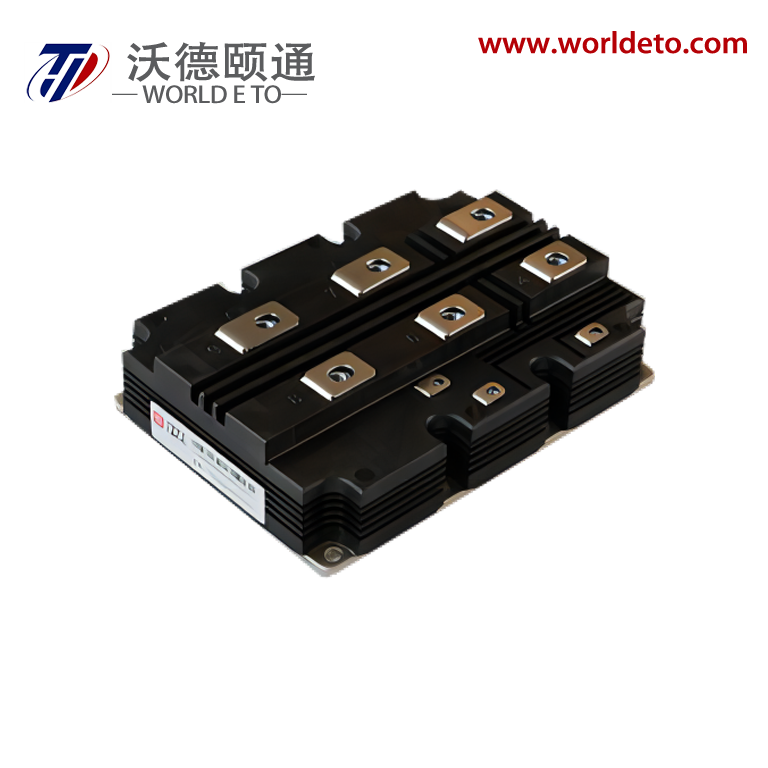

Electric welding machines are the backbone of manufacturing, construction, and metalworking, relying on precise energy control to melt and fuse metals. As demands for higher precision, energy efficiency, and portability grow, the technology powering these machines has evolved dramatically. At the heart of modern welding machines lies a critical component: IGBT modules. Insulated Gate Bipolar Transistors (IGBTs) have replaced older technologies like thyristors (SCRs) and MOSFETs, revolutionizing how welding machines perform. IGBT modules in electric welding machines deliver faster response times, higher energy efficiency, and superior stability, making them indispensable in both small-scale workshops and large industrial settings. Letâs explore how IGBT modules transform welding performance and why theyâve become the standard in modern machines.â

The Role of IGBT Modules in Electric Welding Machinesâ

Electric welding machines convert AC line power into controlled DC or AC current for welding arcs. This conversion requires power electronic switches that can handle high currents and voltages while adjusting output dynamically to maintain arc stability. IGBT modules excel in this role: they combine the high current handling of bipolar transistors with the fast switching speed of MOSFETs, making them ideal for the rapid, precise adjustments needed in welding.â

In a welding machine, IGBT modules act as the "gatekeepers" of energy flow. When the welder initiates an arc, the modules switch on and off at high frequencies (typically 10â100 kHz), regulating the current to match the desired welding parameters (e.g., amperage, voltage, pulse frequency). This high-frequency switching allows for fine-tuning of the arc, ensuring consistent heat input and preventing fluctuations that could weaken welds. Unlike older technologies, which struggle with rapid adjustments, IGBT modules respond in microseconds, making them critical for maintaining stability even in challenging welding conditions.â

Enhancing Efficiency: How IGBT Modules Reduce Energy Wasteâ

Energy efficiency is a key advantage of IGBT modules in electric welding machines, directly impacting operating costs and environmental footprint. Traditional welding machines using thyristors (SCRs) have efficiency ratings as low as 60â70%, wasting significant energy as heat. IGBT modules, by contrast, boost efficiency to 85â95%, thanks to their unique switching characteristics.â

Low Conduction and Switching Lossesâ

IGBT modules minimize two types of energy loss:â

- Conduction Loss: When conducting current, IGBT modules have low on-state resistance, reducing the voltage drop across the device. This means less energy is wasted as heat compared to SCRs, which have higher forward voltage drops.â

- Switching Loss: IGBT modules switch on and off much faster than SCRs (microseconds vs. milliseconds), reducing the energy lost during transitions. This is critical in welding, where frequent switching is needed to adjust arc intensity.â

For example, a 300A IGBT-based welding machine consumes up to 30% less electricity than an equivalent SCR machine during a 1-hour welding cycle. Over time, this translates to substantial cost savings, especially in industrial settings with high welding volumes.â

Optimized Power Conversionâ

Welding machines often operate at variable loads, from low-amperage tack welds to high-amperage structural welds. IGBT modules adjust seamlessly to these changes, converting input power to welding current with minimal waste. Their ability to operate at high frequencies also allows for smaller, lighter transformers and filters in the machine, reducing overall energy loss in the system. This compact design not only improves efficiency but also makes IGBT-based welding machines more portableâa boon for on-site construction or mobile repair work.â

Boosting Stability: Consistent Performance in Weldingâ

Stability is paramount in welding, where even minor fluctuations in current or voltage can cause defects like porosity, spatter, or uneven bead formation. IGBT modules enhance stability through precise control and rapid response, ensuring the arc remains consistent regardless of external variables (e.g., material thickness, electrode speed).â

Precise Arc Controlâ

The high switching frequency of IGBT modules (10â100 kHz) allows for finer control over the welding arc. For instance, in pulse weldingâa technique used for thin materials or decorative weldsâIGBT modules can modulate the current between high and low levels at precise intervals, preventing burn-through while ensuring strong fusion. This level of control is impossible with SCRs, which switch too slowly to achieve such rapid pulses.â

IGBT modules also enable adaptive control systems in modern welding machines. Sensors detect changes in arc length or material resistance, and the modules adjust current within microseconds to compensate. This "self-correcting" capability ensures the arc stays stable even if the welderâs hand shakes or the electrode moves slightly, reducing the skill level required to produce high-quality welds.

â

âProtection Against Faultsâ

Welding environments are harsh, with risks of short circuits, overcurrents, or overheating. IGBT modules integrate built-in protection featuresâsuch as overcurrent shutdown, thermal monitoring, and voltage clampingâthat safeguard both the module and the welding machine. For example, if a short circuit occurs (e.g., the electrode touches the workpiece unexpectedly), the IGBT module can shut off current in microseconds, preventing damage to the machine or injury to the operator.â

This fault tolerance is far superior to SCR-based machines, which rely on external fuses or relays that react more slowly, increasing the risk of component failure. By preventing cascading faults, IGBT modules extend the lifespan of welding machines and reduce downtime for repairs.â

IGBT Modules vs. Traditional Technologies in Welding Machinesâ

To appreciate the impact of IGBT modules, itâs helpful to compare them with older technologies like SCRs and MOSFETs, which dominated welding machines before IGBTs became prevalent.â

IGBT vs. SCR (Thyristor)â

SCRs were once the standard in welding machines for their ability to handle high currents. However, they have critical limitations:â

- Slow Switching: SCRs switch on with a gate pulse but cannot switch off voluntarilyâthey rely on AC voltage zero-crossing, making them unsuitable for DC welding or rapid current adjustments.â

- Poor Efficiency: Higher conduction losses mean SCR machines run hotter and consume more energy.â

- Bulky Design: SCRs require large heat sinks and transformers, making machines heavier and less portable.â

IGBT modules overcome these issues with fast switching, higher efficiency, and compact size, making them ideal for modern DC and pulse welding machines.â

IGBT vs. MOSFETâ

MOSFETs offer fast switching but struggle with high currentsâtheir on-state resistance increases significantly at currents above 100A, leading to excessive heating. IGBT modules, by contrast, handle high currents (up to 1200A in industrial models) with low resistance, combining the best of MOSFET speed and bipolar transistor current capacity. This makes them better suited for heavy-duty welding applications, such as industrial steel fabrication.â

Applications: Where IGBT Modules Shine in Weldingâ

IGBT modules are versatile enough to enhance performance across all types of electric welding machines, from small hobbyist models to large industrial systems.â

MIG/MAG Welding Machinesâ

Metal Inert Gas (MIG) and Metal Active Gas (MAG) welding rely on a continuous wire electrode and shielding gas. IGBT modules in these machines precisely control wire feed speed and arc voltage, ensuring smooth wire melting and minimal spatter. Their rapid response is especially valuable for welding thin materials (e.g., automotive body panels), where even small current fluctuations can cause burn-through.â

TIG Welding Machinesâ

Tungsten Inert Gas (TIG) welding demands exceptional arc stability for clean, precise welds (e.g., in aerospace or jewelry making). IGBT modules enable microsecond-level adjustments to the DC or AC arc, maintaining a steady heat input even when welding heat-sensitive alloys like aluminum or titanium. Pulse TIG welding, which reduces heat input by alternating high and low currents, is only possible with the fast switching of IGBT modules.â

Arc Welding Machinesâ

Stick (Shielded Metal Arc) welding uses a consumable electrode coated in flux. IGBT modules in these machines stabilize the arc during electrode changes and prevent "sticking" by quickly reducing current if the electrode touches the workpiece. This makes stick welding easier for beginners and more reliable in rugged environments (e.g., construction sites).â

Industrial Robotic Welding Cellsâ

Automated welding robots require consistent, repeatable performance. IGBT modules in robotic welding machines ensure each weld matches the programmed parameters, even across hundreds of cycles. Their integration with digital control systems allows for real-time adjustments based on sensor feedback (e.g., arc length monitoring), ensuring perfect welds in mass production (e.g., automotive assembly lines).â

FAQ: IGBT Modules in Electric Welding Machinesâ

Why are IGBT modules better for portable welding machines?â

IGBT modules are smaller and more efficient than SCRs, allowing manufacturers to build lighter, more compact machines that still deliver high power. Their low heat generation also reduces the need for large heat sinks, making them ideal for on-site or mobile welding.â

How do IGBT modules improve weld quality?â

By enabling precise current control and rapid adjustments, IGBT modules maintain a stable arc, reducing spatter, porosity, and uneven bead formation. This results in stronger, cleaner welds that meet strict industry standards (e.g., AWS or ISO certifications).â

What is the typical lifespan of IGBT modules in welding machines?â

With proper maintenance (e.g., clean heat sinks, adequate cooling), IGBT modules can last 5â10 years in industrial use. This is longer than SCRs, which degrade faster due to higher operating temperatures.â

Can IGBT-based welding machines handle all types of metals?â

Yes. IGBT modulesâ ability to adjust current, voltage, and pulse frequency makes them suitable for welding steel, aluminum, copper, and alloys. They excel at both thin and thick materials, from 0.5mm sheet metal to 50mm structural steel.â

How do I know if an IGBT module in my welding machine is failing?â

Signs include inconsistent arc stability, frequent tripping (due to protection features activating), excessive heat from the machine, or visible damage (e.g., burn marks on the module). Prompt replacement is critical to prevent further damage.

Table of Contents

- IGBT Modules in Electric Welding Machines: How They Enhance Efficiency and Stability​

- The Role of IGBT Modules in Electric Welding Machines​

- Enhancing Efficiency: How IGBT Modules Reduce Energy Waste​

- IGBT Modules vs. Traditional Technologies in Welding Machines​

- Applications: Where IGBT Modules Shine in Welding​

-

FAQ: IGBT Modules in Electric Welding Machines​

- Why are IGBT modules better for portable welding machines?​

- How do IGBT modules improve weld quality?​

- What is the typical lifespan of IGBT modules in welding machines?​

- Can IGBT-based welding machines handle all types of metals?​

- How do I know if an IGBT module in my welding machine is failing?​