plating rectifier

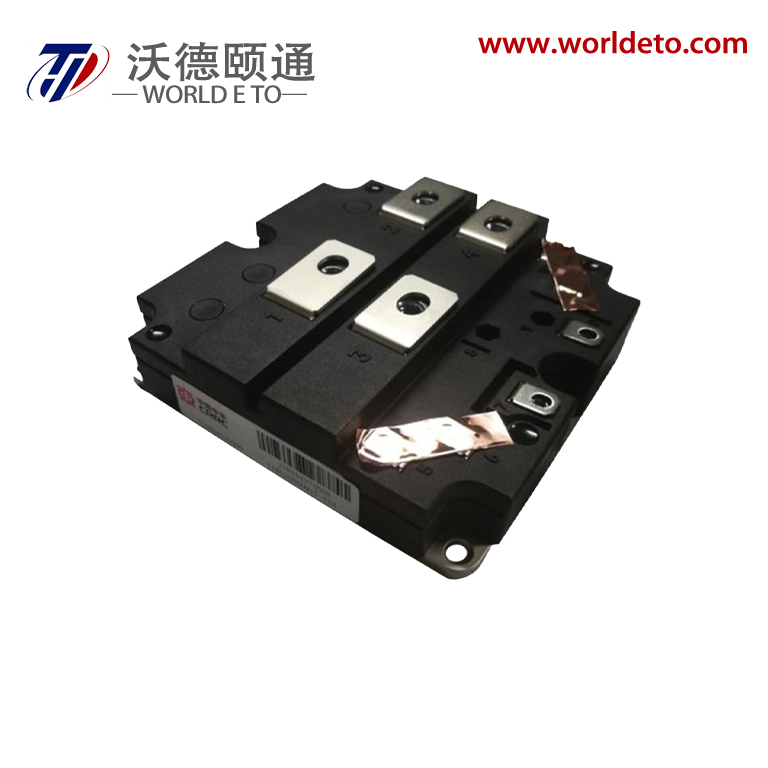

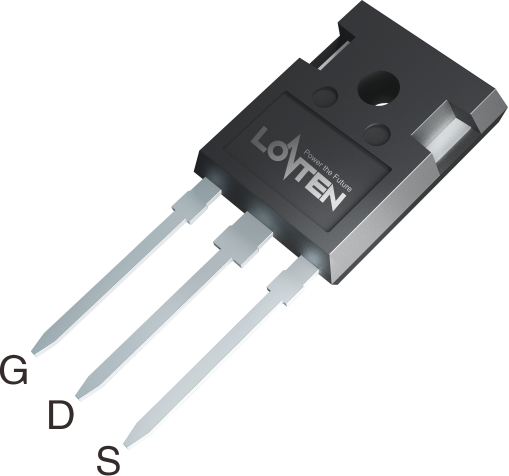

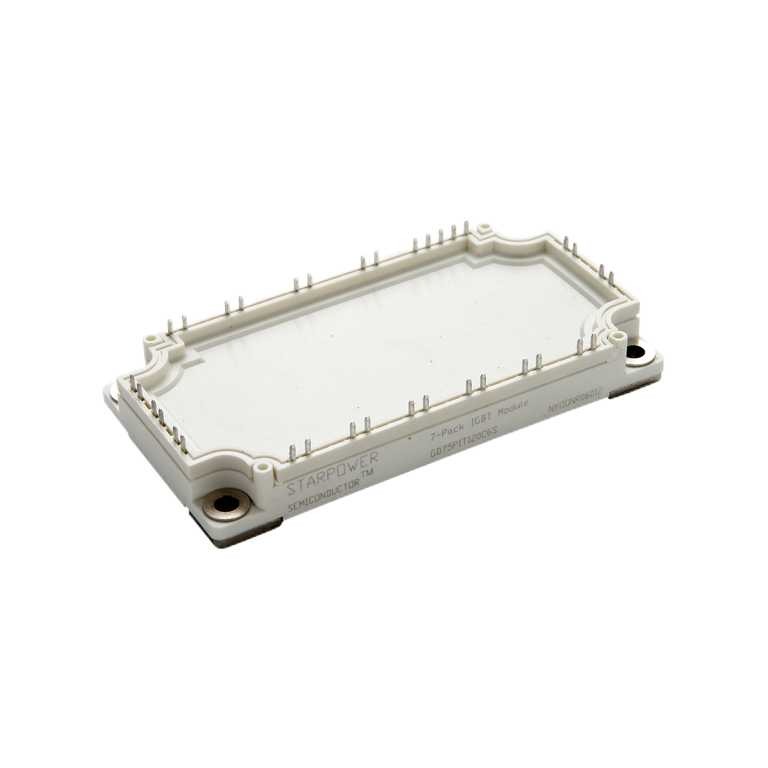

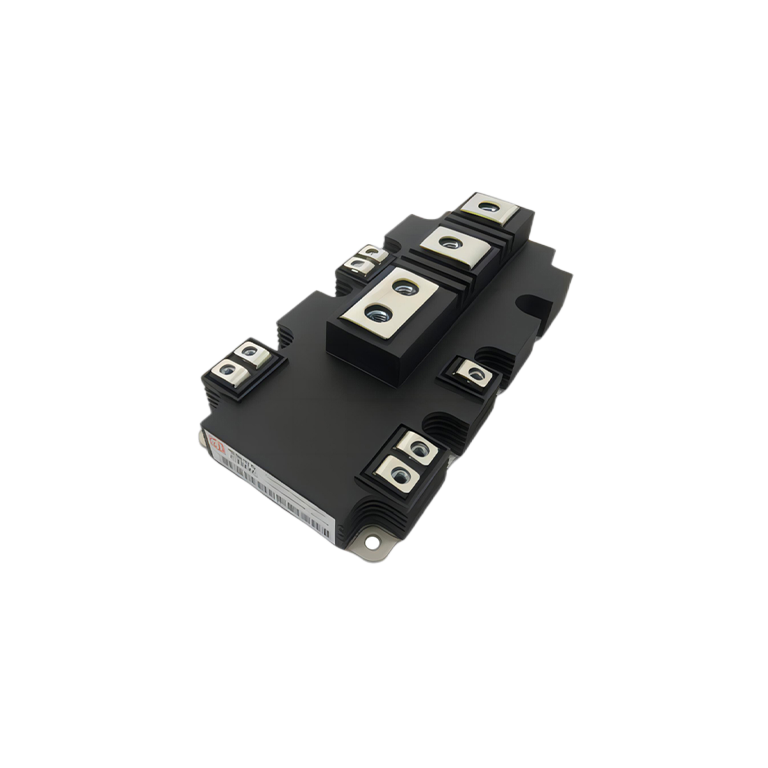

A plating rectifier serves as the cornerstone of electroplating operations, converting alternating current (AC) into direct current (DC) to facilitate the electrochemical deposition process. This specialized power supply equipment plays a crucial role in various surface treatment applications, from decorative chrome plating to industrial hard chrome coating processes. The plating rectifier ensures precise voltage and current control, which directly impacts the quality, uniformity, and adherence of plated coatings on substrates. Modern plating rectifiers incorporate advanced switching technology, typically employing silicon controlled rectifiers (SCR) or insulated gate bipolar transistors (IGBT) to achieve superior performance characteristics. These units feature comprehensive monitoring systems that track critical parameters including output voltage, current density, temperature fluctuations, and operational efficiency. The technological architecture of contemporary plating rectifiers emphasizes energy efficiency, with many models achieving conversion efficiencies exceeding 90 percent through optimized transformer designs and intelligent control algorithms. Safety mechanisms are integrated throughout the system, including overcurrent protection, thermal shutdown capabilities, and ground fault detection to ensure operator safety and equipment longevity. The plating rectifier typically consists of a step-down transformer, rectification circuits, filtering components, and sophisticated control electronics that work in harmony to deliver stable, ripple-free DC output. Applications span across automotive manufacturing, aerospace components, electronic device production, jewelry finishing, and architectural hardware treatment. The versatility of modern plating rectifiers allows them to accommodate various electroplating processes, including copper plating, nickel plating, zinc coating, and precious metal deposition. These systems can be configured for both rack plating and barrel plating operations, with adjustable parameters to optimize results for different substrate materials and coating requirements.