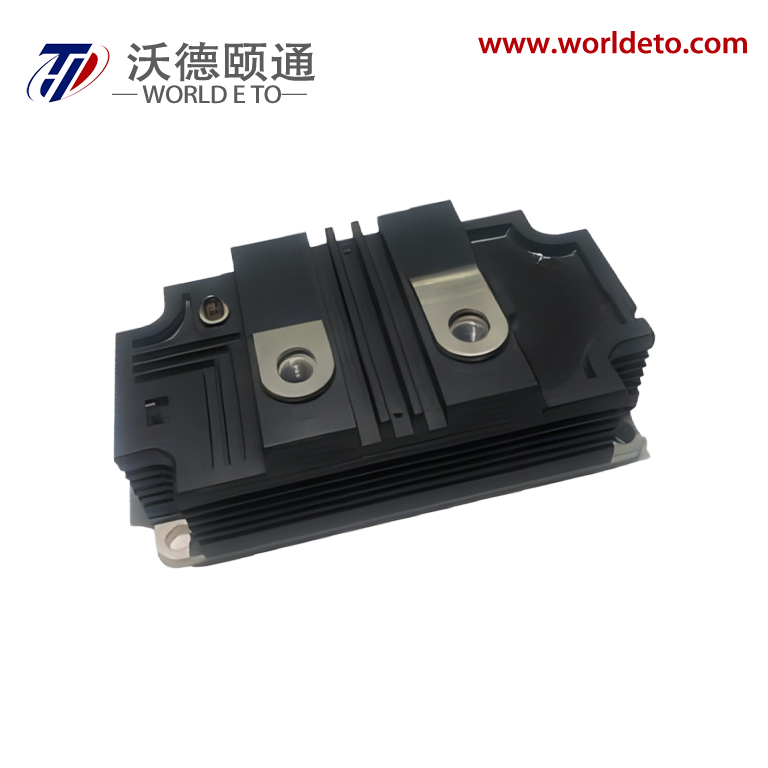

servo drive amplifier

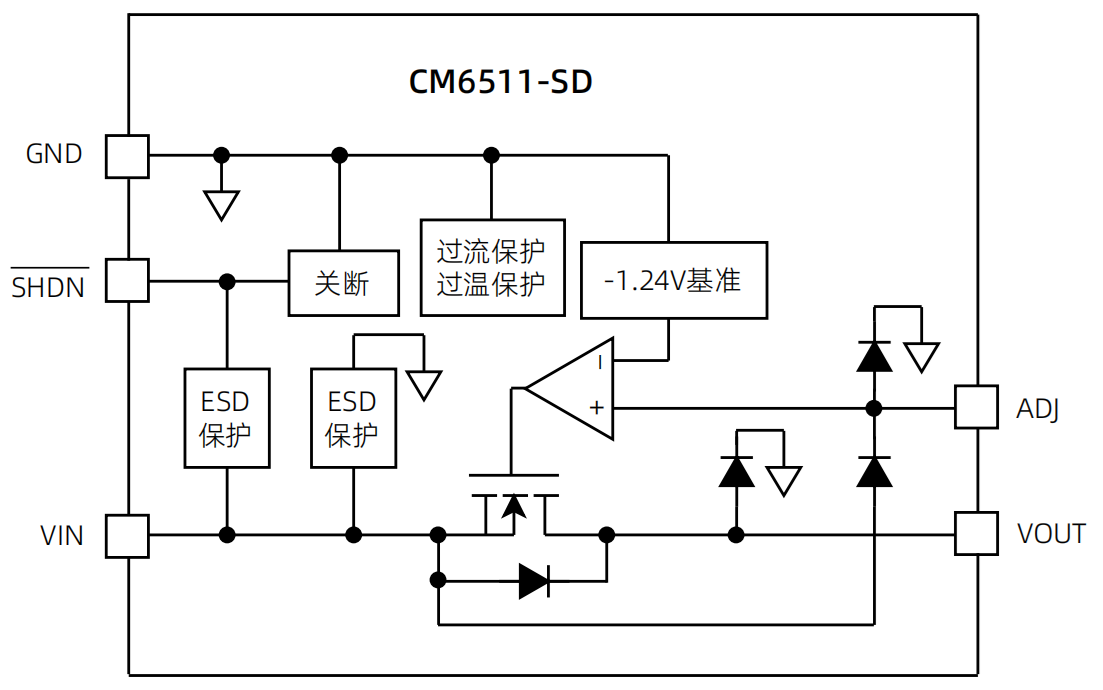

A servo drive amplifier represents a sophisticated electronic control device that transforms low-power command signals into high-power outputs capable of driving servo motors with exceptional precision and reliability. This advanced control system serves as the critical interface between digital control commands and mechanical motion, enabling precise positioning, speed control, and torque management in automated systems. The servo drive amplifier processes feedback signals from encoders or resolvers to maintain accurate motor performance through closed-loop control algorithms. Modern servo drive amplifier units incorporate pulse width modulation technology to deliver smooth, efficient power conversion while minimizing electromagnetic interference and heat generation. These devices feature comprehensive protection circuits that safeguard against overcurrent, overvoltage, and thermal overload conditions, ensuring long-term operational stability. The servo drive amplifier architecture includes signal conditioning circuits, power conversion stages, and intelligent control processors that work together to achieve superior motion control performance. Advanced models offer multiple communication interfaces including EtherCAT, CANopen, and Modbus protocols for seamless integration into industrial networks. The servo drive amplifier design emphasizes compact form factors while maintaining robust construction suitable for harsh industrial environments. Temperature management systems within the servo drive amplifier ensure consistent performance across wide operating ranges. Digital signal processing capabilities enable real-time parameter adjustment and system optimization. The servo drive amplifier technology continues evolving with enhanced algorithms, improved power density, and reduced electromagnetic emissions to meet increasingly demanding automation requirements in manufacturing, robotics, and precision machinery applications.