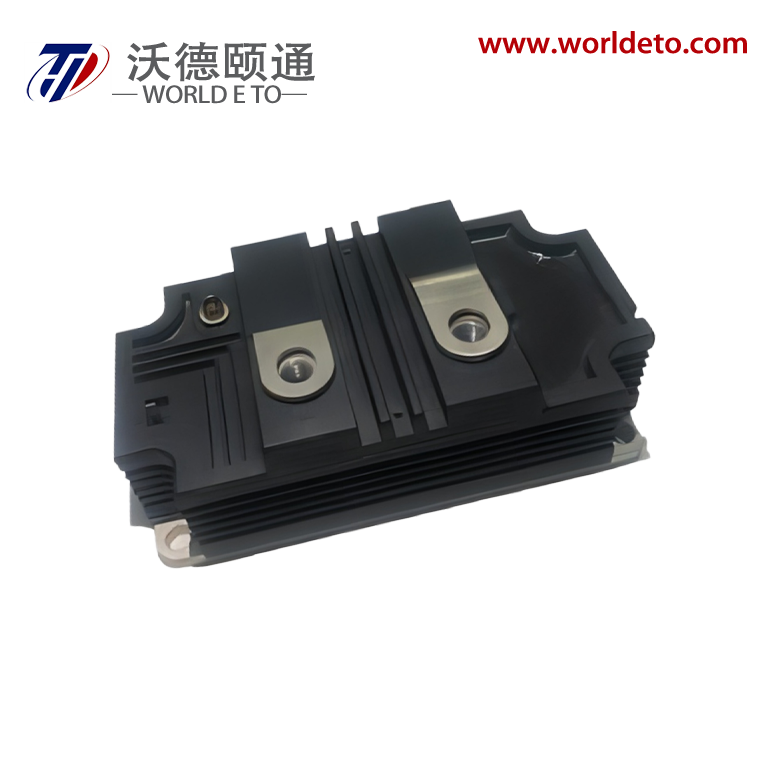

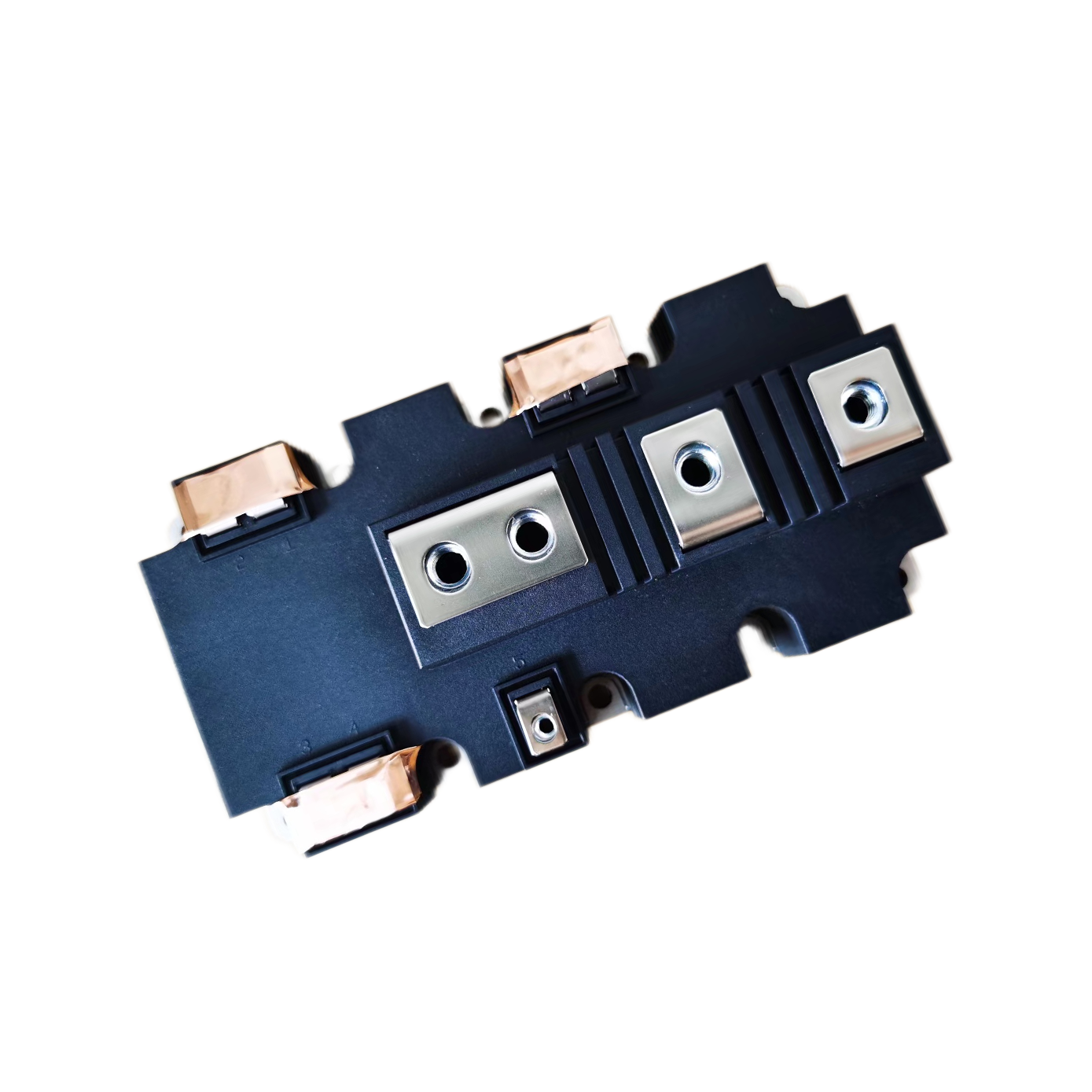

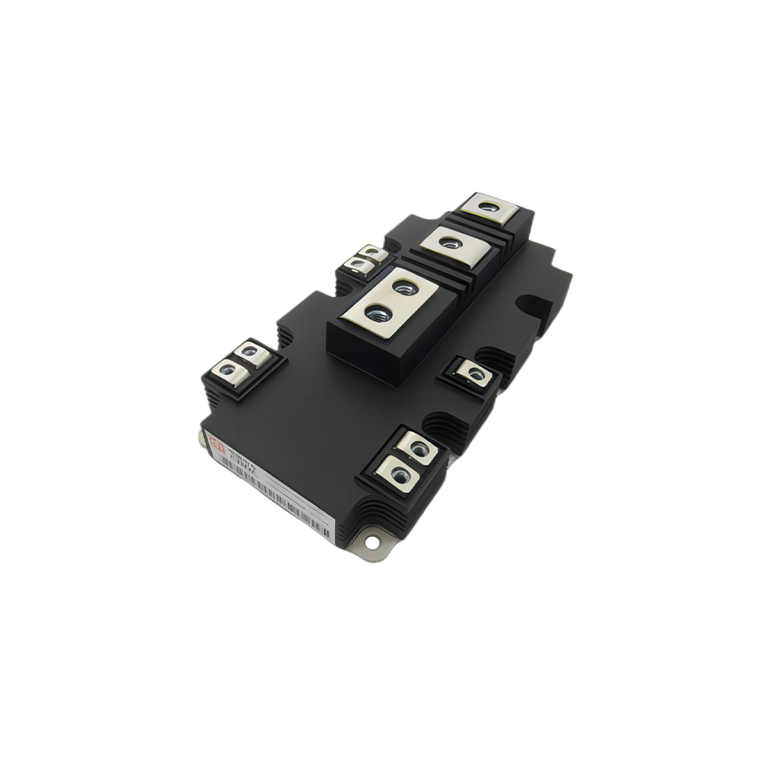

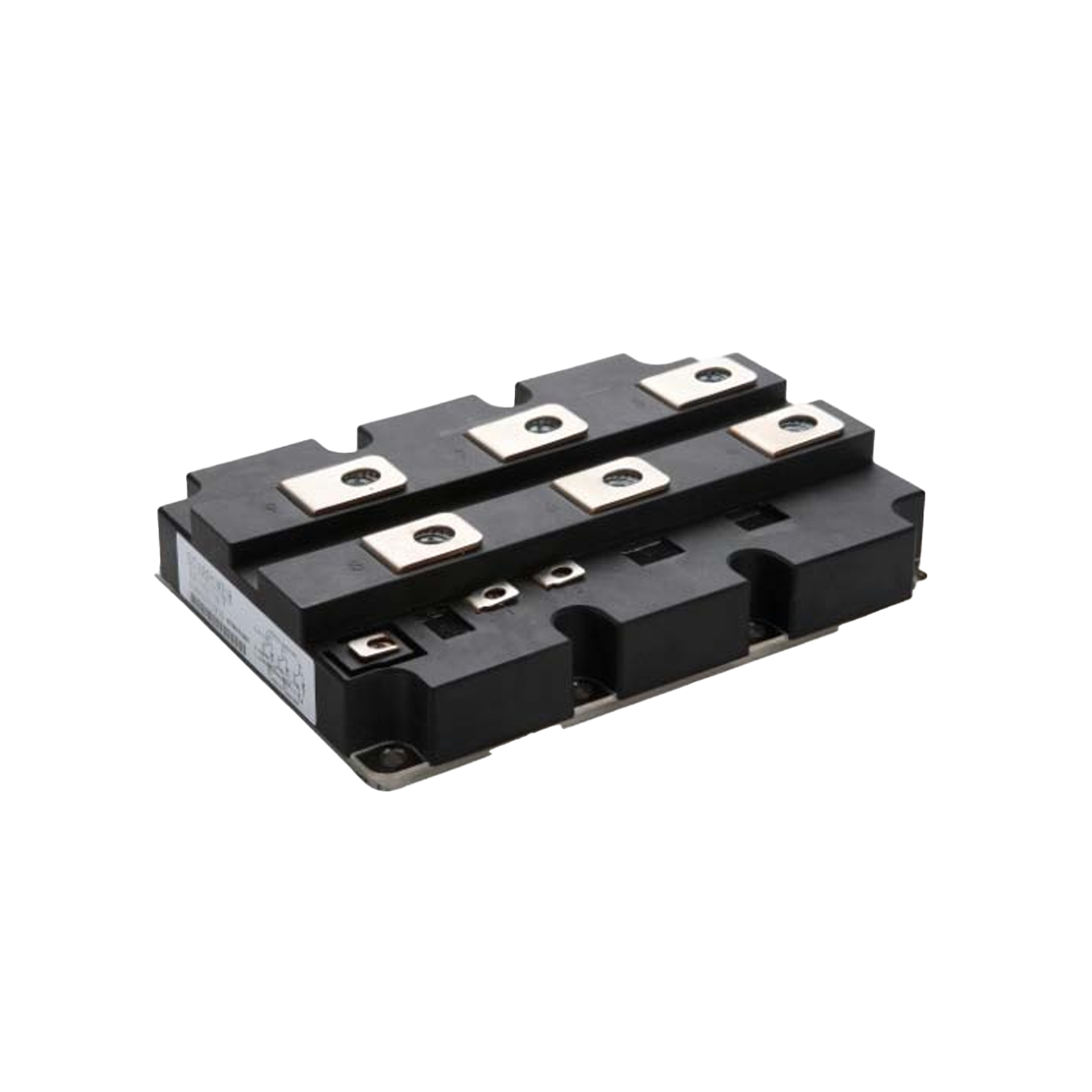

high power thyristor

High power thyristor technology represents a cornerstone of modern power electronics, delivering exceptional switching capabilities for industrial applications requiring robust electrical control. These semiconductor devices function as electronically controlled switches, managing substantial electrical currents and voltages with remarkable precision. The high power thyristor operates through a unique four-layer silicon structure that enables it to handle kilovolts of voltage and thousands of amperes of current, making it indispensable for heavy-duty electrical systems. The device remains in an off state until triggered by a gate signal, then switches to a conducting state, maintaining conduction until the current drops below a holding threshold. This characteristic makes the high power thyristor ideal for applications demanding reliable switching performance under extreme electrical conditions. Technological features include superior thermal management through advanced packaging designs, enhanced surge current capability, and optimized gate sensitivity for consistent triggering. Modern high power thyristor designs incorporate innovative semiconductor materials and manufacturing processes that extend operational lifespan while maintaining stable performance parameters. The device exhibits excellent blocking characteristics in both forward and reverse directions, providing bidirectional voltage blocking capabilities essential for AC applications. Applications span diverse industries including steel manufacturing, aluminum smelting, railway traction systems, and renewable energy conversion. In steel production, these devices control massive electric arc furnaces, while in transportation, they manage propulsion systems for locomotives and subway cars. Power transmission systems rely on high power thyristor technology for HVDC converters and reactive power compensation. The versatility extends to motor drive applications, where precise speed control and torque management are critical. Manufacturing facilities utilize these devices in welding equipment, induction heating systems, and electrochemical processes. The high power thyristor continues evolving with enhanced switching speeds, improved thermal characteristics, and greater integration capabilities, positioning it as a fundamental component in next-generation power systems requiring exceptional reliability and performance standards.