Outstanding Reliability and Extended Operational Lifespan

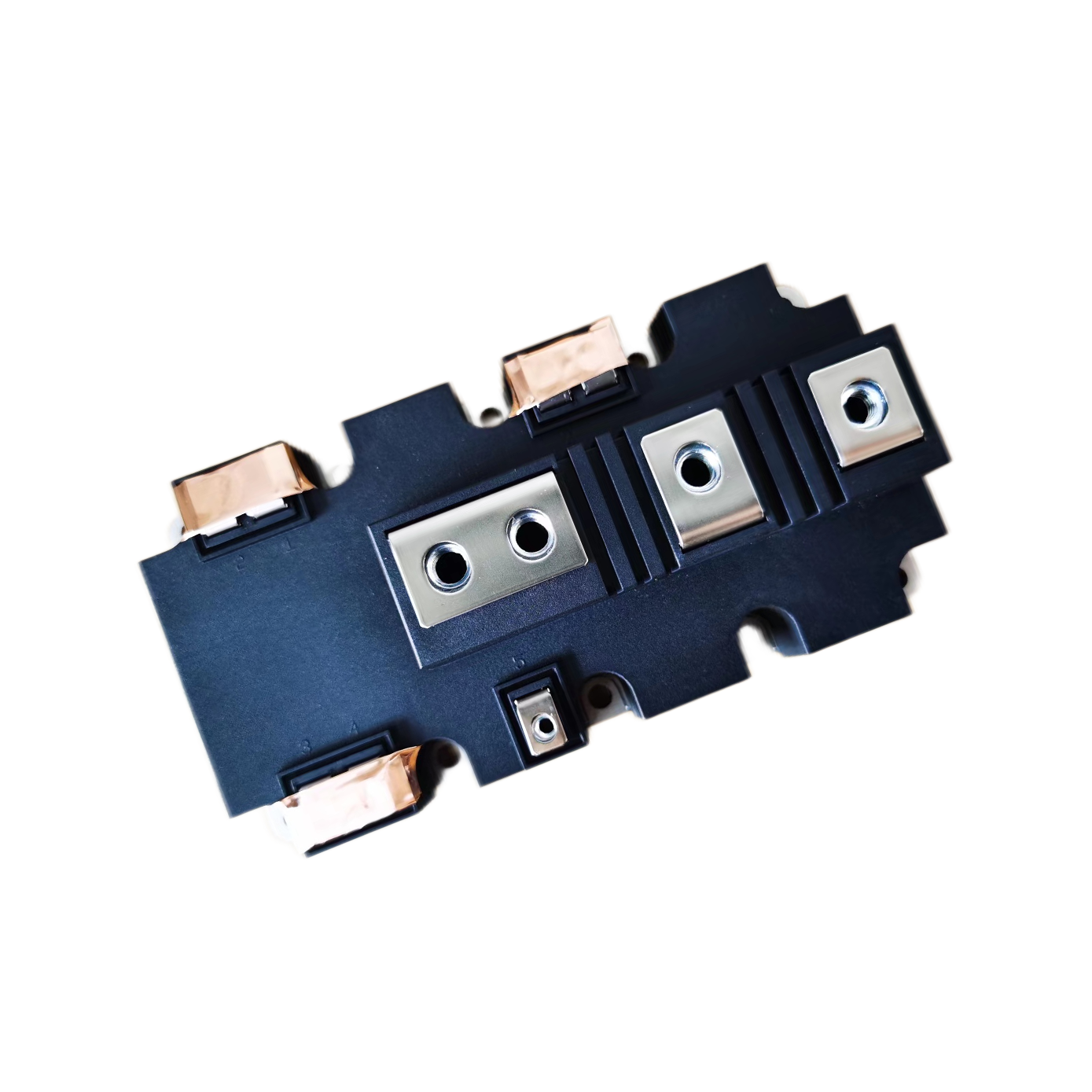

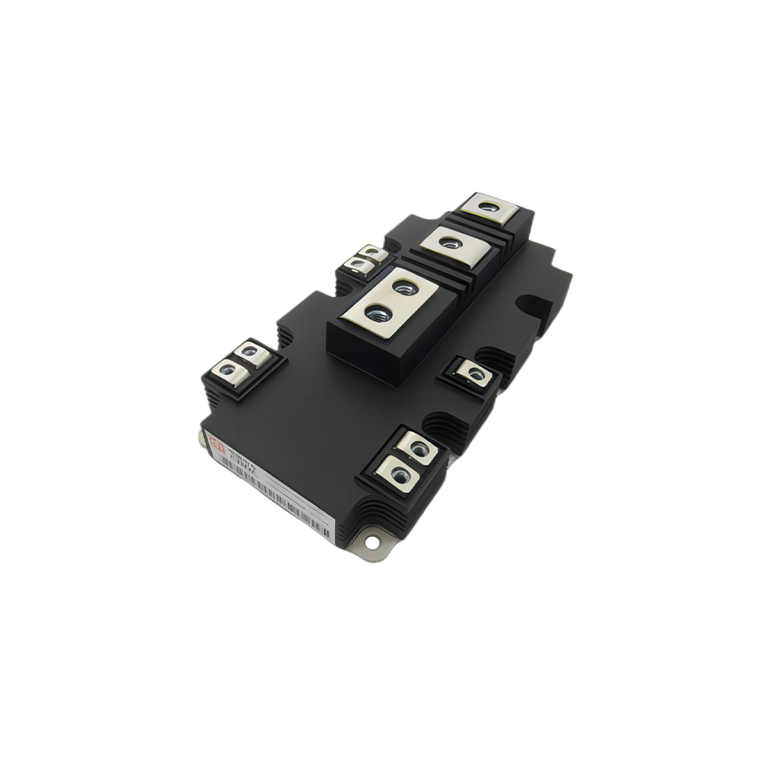

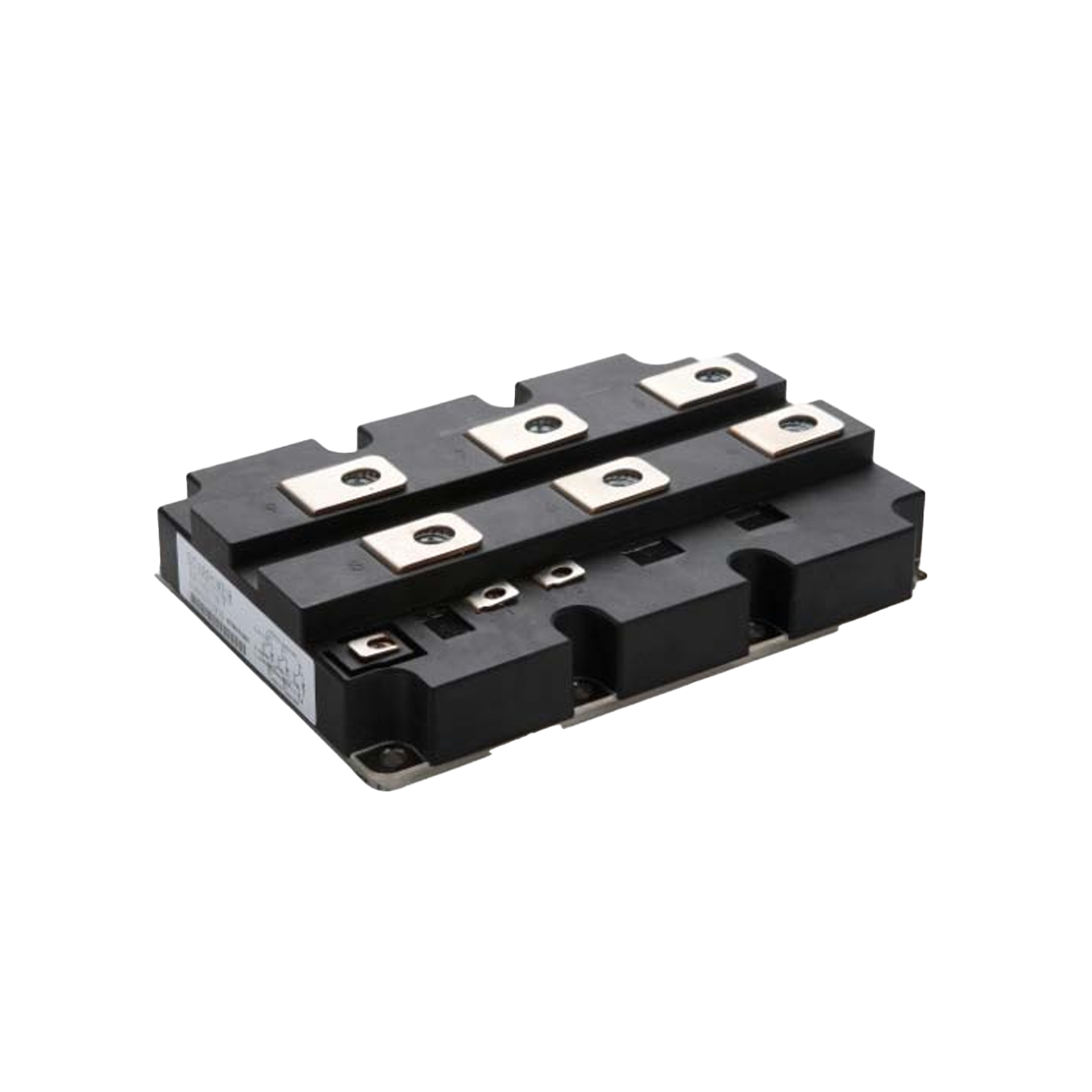

The high voltage thyristor establishes new standards for reliability through rigorous design validation, premium material selection, and comprehensive quality assurance programs that ensure exceptional performance throughout extended operational periods. This superior reliability stems from extensive failure mode analysis and proactive design modifications that eliminate potential weakness points commonly found in conventional power devices. The device incorporates redundant protection mechanisms that provide multiple layers of safeguards against overvoltage, overcurrent, and thermal stress conditions that could compromise operational integrity. Manufacturing processes utilize advanced quality control techniques including statistical process monitoring, automated testing procedures, and traceability systems that verify each component meets stringent performance specifications. Users benefit from reduced maintenance costs and minimal unplanned downtime because the high voltage thyristor maintains consistent performance characteristics throughout its operational lifespan. The reliability enhancement results from specialized packaging technologies that protect sensitive semiconductor junctions from environmental contaminants, mechanical stress, and thermal cycling effects. Accelerated aging tests validate long-term performance predictions and identify potential degradation mechanisms before they affect field reliability. The high voltage thyristor features self-monitoring capabilities that track operational parameters and provide early indicators of potential issues before they develop into critical failures. Quality validation includes extensive environmental testing under extreme temperature conditions, humidity exposure, vibration stress, and electromagnetic interference to verify robust operation. The device demonstrates exceptional consistency across production batches through standardized manufacturing processes and comprehensive incoming material inspections. Integration advantages include compatibility with existing monitoring systems and maintenance protocols used in industrial facilities. Environmental resistance features enable reliable operation in challenging conditions including outdoor installations, marine environments, and industrial facilities with harsh atmospheric conditions. The high voltage thyristor supports predictive maintenance programs through built-in diagnostic capabilities that monitor device health parameters continuously.