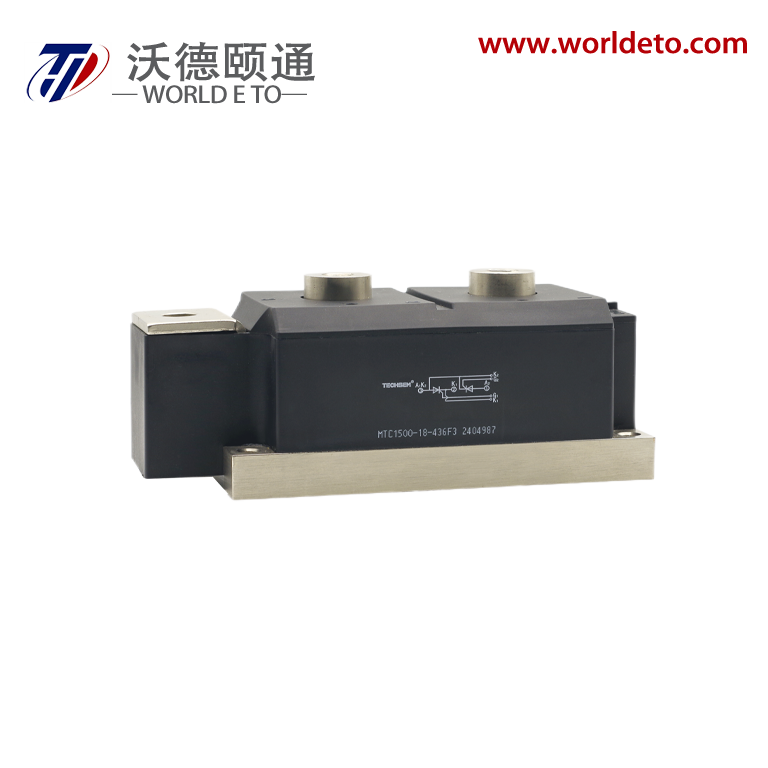

transistor for power supply

The transistor for power supply represents a fundamental semiconductor device that serves as the backbone of modern power conversion and regulation systems. This essential component functions as an electronic switch or amplifier, controlling electrical current flow with remarkable precision and efficiency. Power supply transistors are specifically engineered to handle substantial electrical loads while maintaining optimal performance under demanding operational conditions. These sophisticated devices utilize three primary terminals - the base, collector, and emitter in bipolar junction transistors, or gate, drain, and source in field-effect transistors - to manage power distribution effectively. The transistor for power supply operates by modulating current flow through controlled signal application, enabling precise voltage regulation and current management across diverse electronic systems. Modern power supply transistors incorporate advanced semiconductor materials such as silicon carbide and gallium nitride, which provide superior thermal conductivity and higher switching frequencies compared to traditional silicon-based alternatives. These technological improvements allow the transistor for power supply to operate at elevated temperatures while maintaining exceptional reliability and longevity. The device's ability to rapidly switch between conducting and non-conducting states makes it invaluable for pulse-width modulation applications, switch-mode power supplies, and DC-DC conversion circuits. Power supply transistors are manufactured using sophisticated fabrication techniques that ensure consistent performance characteristics and minimal variation between individual components. The transistor for power supply finds extensive applications across numerous industries, including automotive electronics, telecommunications infrastructure, industrial automation systems, consumer electronics, and renewable energy conversion systems. These versatile components enable efficient power management in everything from smartphone chargers to electric vehicle charging stations, demonstrating their critical importance in contemporary technology ecosystems.