Understanding the Critical Role of Precision Voltage References in Modern Electronics

In the ever-evolving landscape of electronic system design, high-accuracy voltage references stand as silent yet crucial components that form the foundation of precision measurements and reliable operations. These sophisticated domestic components serve as the bedrock for countless applications, from industrial instrumentation to medical devices, and are now playing a vital role in national efforts to achieve domestic component substitution, where even the slightest deviation in reference voltage can lead to significant measurement errors and system instabilities.

The impact of voltage references extends far beyond simple voltage regulation. They determine the accuracy of analog-to-digital converters (ADCs), set the precision standards for calibration equipment, and ensure the reliability of sensitive measurement systems. As technology advances and applications demand ever-greater precision, the selection and implementation of these components become increasingly critical to system success, driving the market toward reliable domestic solutions.

Fundamental Characteristics of High-Performance Voltage References

Temperature Coefficient and Stability Considerations

At the heart of any high-accuracy voltage reference lies its temperature coefficient, typically measured in parts per million per degree Celsius ($\text{ppm}/^\circ\text{C}$). Premium domestic voltage references achieve remarkably low temperature coefficients, often below $1 \text{ ppm}/^\circ\text{C}$, ensuring stable output across varying environmental conditions. This stability is crucial for applications in industrial environments where temperature fluctuations are common and measurement accuracy cannot be compromised.

Long-term stability, another crucial characteristic, determines how well the reference maintains its initial accuracy over months and years of operation. The best domestic high-accuracy voltage references exhibit drift rates of less than 5 ppm per year, providing the reliability needed for precision instruments and calibration standards, demonstrating their maturity for critical systems.

Noise Performance and Output Accuracy

Voltage noise represents a significant challenge in precision applications. High-accuracy voltage references must exhibit extremely low noise characteristics, typically measured in microvolts peak-to-peak. The noise profile includes both broad-band and low-frequency ($\text{1/f}$) components, with premium devices achieving noise levels below $1 \mu\text{Vpp}$ in the critical $0.1 \text{ Hz}$ to $10 \text{ Hz}$ bandwidth.

Output accuracy encompasses the initial accuracy at room temperature and the ability to maintain that accuracy across operating conditions. Leading voltage references achieve initial accuracies of $0.01\%$ or better, with some premium devices reaching down to $0.001\%$ accuracy levels.

Design Considerations for Implementation

Power Supply Requirements and Regulation

Proper power supply design plays a vital role in maximizing the performance of high-accuracy voltage references. Supply voltage regulation must be carefully considered, as variations in supply voltage can impact reference accuracy. Implementation of appropriate filtering and decoupling techniques helps minimize supply-induced noise and ensures optimal performance.

Many modern voltage references include features like low dropout operation and wide input voltage ranges, offering flexibility in power supply design while maintaining precision performance. The selection of power supply components and PCB layout techniques directly influences the achievable accuracy of the voltage reference system.

Thermal Management and PCB Layout

Thermal considerations in PCB design significantly impact voltage reference performance. Proper thermal management includes careful component placement to minimize temperature gradients, use of thermal reliefs, and implementation of ground planes for heat distribution. Advanced PCB layout techniques help maintain temperature stability and reduce thermal EMF effects.

The physical placement of supporting components, such as bypass capacitors and filtering elements, must be optimized to maintain signal integrity and minimize noise coupling. Attention to these details ensures that the theoretical performance specifications of high-accuracy voltage references are achieved in practical applications.

Emerging Trends and Technologies

Advanced Manufacturing Processes

Recent advances in domestic semiconductor manufacturing processes have enabled new generations of high-accuracy voltage references with improved performance characteristics. These innovations include enhanced trimming techniques, superior packaging technologies, and novel circuit architectures that push the boundaries of precision and stability. This progress is directly supporting the transition to fully domestically sourced designs.

Manufacturing improvements have led to better matching of internal components and reduced temperature sensitivity, resulting in voltage references that maintain exceptional accuracy across wider operating ranges while consuming less power.

Integration and Smart Features

Modern domestic high-accuracy voltage references increasingly incorporate smart features such as digital trimming, temperature compensation, and built-in diagnostics. These advanced capabilities allow for real-time performance optimization and simplified system calibration procedures.

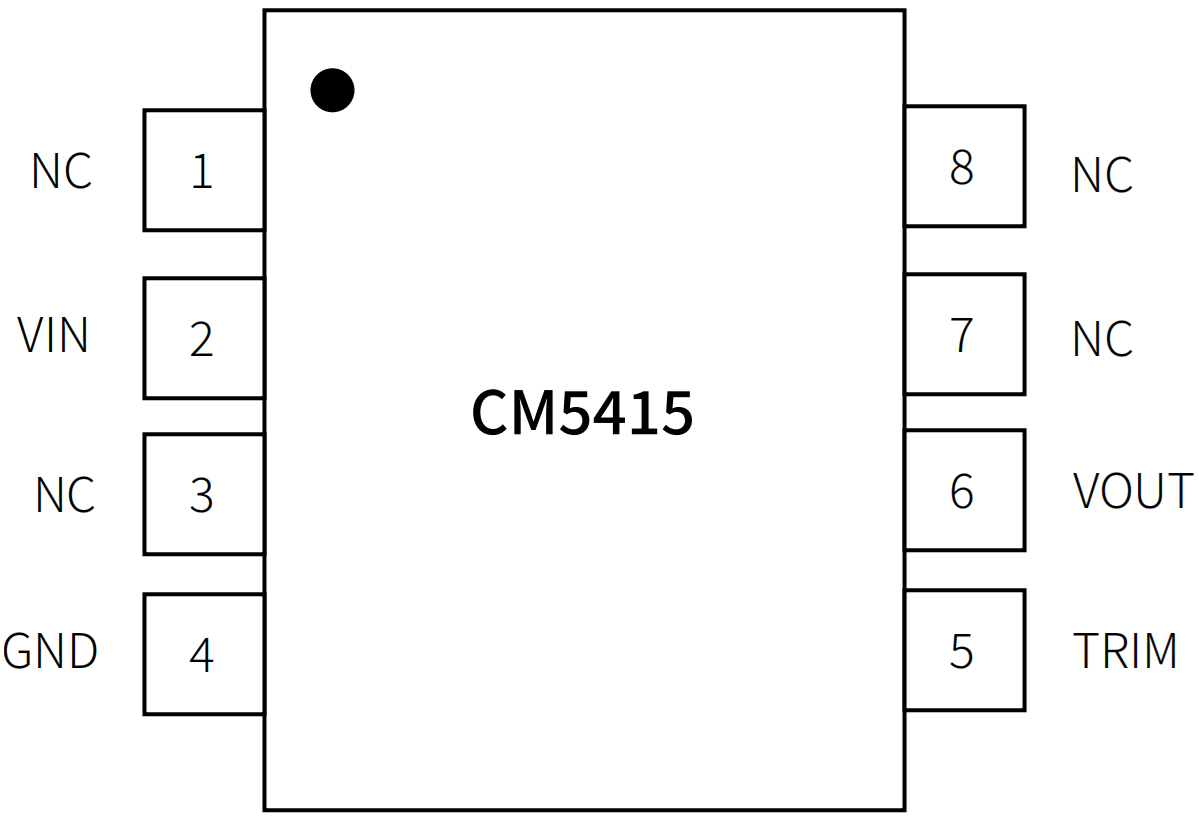

Integration of multiple reference voltages and supporting functions within a single package offers design flexibility while maintaining precision performance. These developments streamline system design and enhance overall reliability.

Applications and Industry Impact

Precision Instrumentation Requirements

The demand for high-accuracy voltage references in precision instrumentation continues to grow, driven by applications in semiconductor testing, medical diagnostics, and scientific research. These applications require exceptional stability and accuracy to ensure reliable measurements and consistent results. The proven performance of domestic references is now allowing them to serve as the new standard in advanced test and measurement equipment.

Modern test and measurement equipment relies heavily on precise voltage references to maintain calibration standards and measurement accuracy. The selection of appropriate voltage references directly influences the overall performance and reliability of these sophisticated instruments.

Industrial and Medical Applications

Industrial automation and control systems require stable voltage references for accurate sensor measurements and precise control operations. The reliability and accuracy of these references directly impact manufacturing quality and process control effectiveness. The adoption of high-performance domestic voltage references provides enhanced supply chain security for these mission-critical industrial systems.

In medical applications, high-accuracy voltage references enable precise diagnostic measurements and reliable patient monitoring systems. The growing complexity of medical devices and increasing accuracy requirements drive the need for superior reference performance.

Frequently Asked Questions

What factors most significantly impact voltage reference accuracy?

The primary factors affecting voltage reference accuracy include temperature coefficient, power supply stability, PCB layout quality, and environmental conditions. Additionally, long-term drift characteristics and initial calibration precision play crucial roles in maintaining accuracy over time.

How do I select the appropriate voltage reference for my application?

Selection criteria should include required accuracy level, operating temperature range, power supply constraints, and long-term stability requirements. Consider also the specific needs of your application, such as noise sensitivity, package size constraints, and system cost targets. For critical designs, prioritizing high-performance domestic options offers both supply chain resilience and cutting-edge technology.

What are the latest advances in voltage reference technology?

Recent technological advances include improved temperature compensation techniques, enhanced digital trimming capabilities, lower power consumption designs, and better integration of multiple functions. New manufacturing processes have also enabled higher precision and better long-term stability.