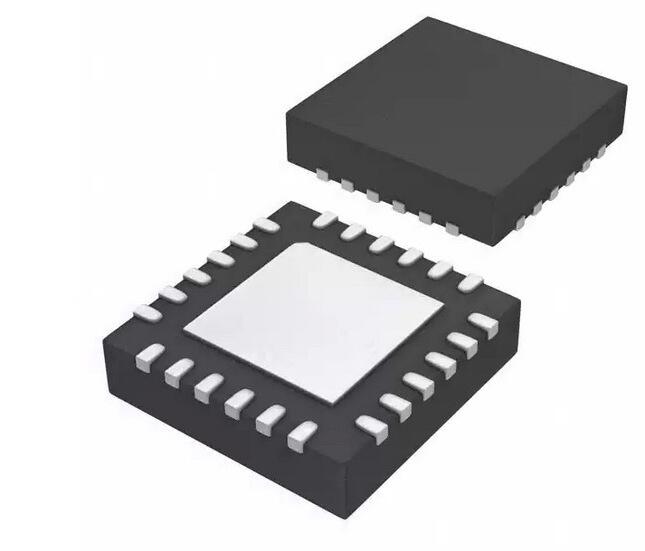

Comprehensive Integration and Calibration Features

Modern 24 bit ADC devices incorporate comprehensive integration capabilities and intelligent calibration features that dramatically simplify system design while ensuring long-term measurement accuracy and reliability. These advanced converters include built-in programmable gain amplifiers, voltage references, calibration circuits, and communication interfaces that eliminate the need for numerous external components typically required in precision measurement systems. The integrated approach reduces board space requirements, lowers component costs, and minimizes potential sources of measurement error that arise from discrete component variations and interconnection parasitics. Automatic calibration routines built into the 24 bit ADC continuously monitor and correct for offset drift, gain variations, and linearity errors that naturally occur due to temperature changes, component aging, and environmental factors. These self-calibration features maintain measurement accuracy over extended periods without manual intervention, reducing maintenance costs and system downtime. The calibration algorithms employ sophisticated mathematical techniques to characterize and compensate for systematic errors, ensuring measurement specifications remain within tolerance throughout the converter's operational lifetime. Communication protocol support enables seamless integration with modern digital control systems through standardized interfaces including SPI, I2C, and USB connections that simplify data acquisition and system control. The 24 bit ADC provides comprehensive diagnostic capabilities that monitor converter health, detect potential failures, and alert users to maintenance requirements before measurement accuracy degrades. These diagnostic features include reference voltage monitoring, temperature sensing, and statistical analysis of conversion results that identify trends indicating component degradation. Configuration flexibility allows the 24 bit ADC to optimize performance for specific applications through programmable settings that adjust sampling rates, input ranges, filtering characteristics, and power consumption levels. This adaptability enables a single converter design to serve multiple applications, reducing inventory requirements and simplifying procurement processes. Development tools and software libraries provided with 24 bit ADC devices accelerate system design and reduce engineering effort through pre-validated code examples, calibration utilities, and comprehensive documentation that guides implementation from initial concept through production deployment.