industrial ldo supplier

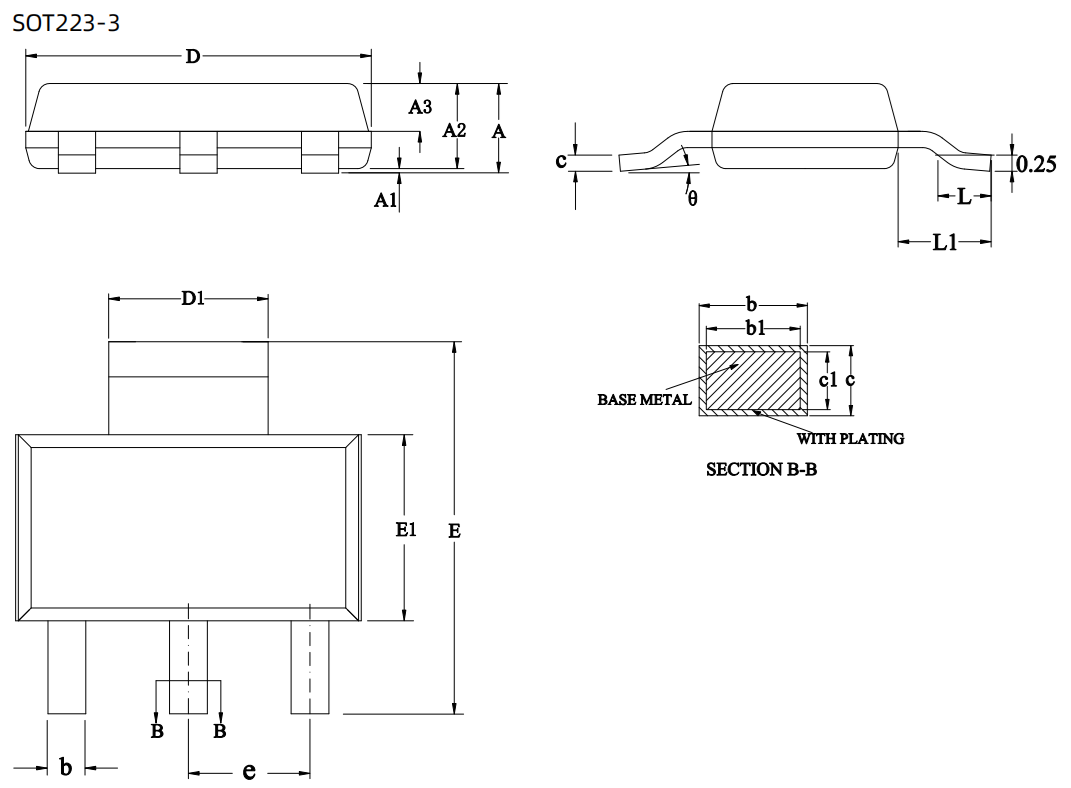

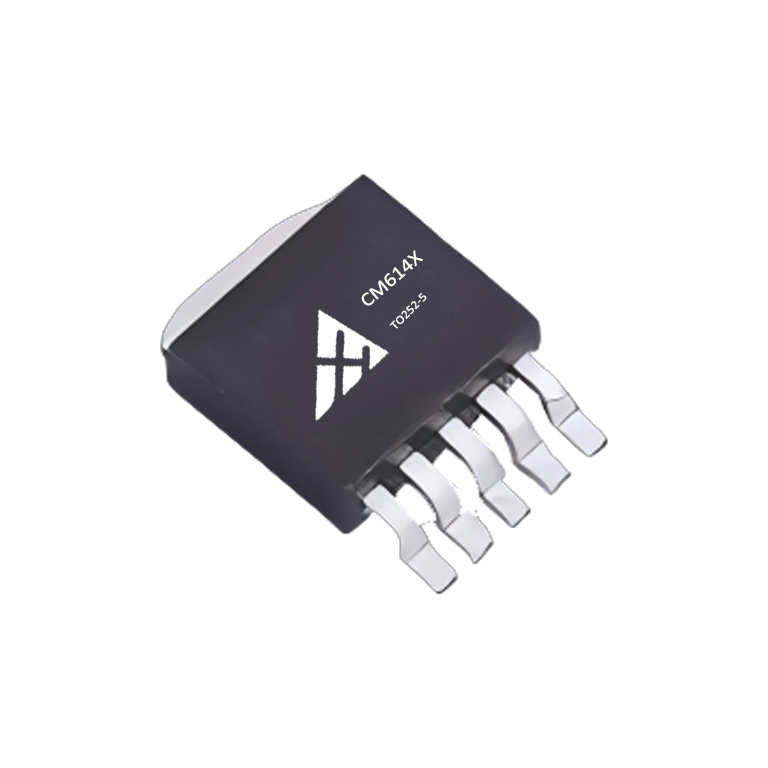

An industrial ldo supplier serves as a critical component provider for manufacturing operations that require stable, low-dropout voltage regulation in harsh environments. These suppliers specialize in delivering linear voltage regulators designed specifically for industrial applications where consistent power delivery is essential. The main functions of an industrial ldo supplier encompass providing reliable voltage conversion, noise reduction, and power management solutions that meet stringent industrial standards. Industrial LDO regulators function by maintaining a constant output voltage despite fluctuations in input voltage or load current, making them indispensable for sensitive electronic equipment. The technological features of products from an industrial ldo supplier include wide operating temperature ranges, typically from -40°C to 125°C, exceptional line and load regulation capabilities, and robust protection mechanisms against overcurrent, thermal shutdown, and reverse voltage conditions. These suppliers also offer enhanced package options that withstand vibration, shock, and moisture exposure common in industrial settings. Advanced industrial ldo supplier products feature ultra-low dropout voltages, often below 300mV, enabling efficient operation even when input and output voltages are closely matched. Applications for industrial ldo supplier products span across factory automation systems, process control equipment, industrial IoT devices, motor drives, and measurement instrumentation. Manufacturing facilities rely on these suppliers for powering programmable logic controllers, human-machine interfaces, and communication modules that demand clean, stable power sources. The precision agriculture sector utilizes industrial ldo supplier products in sensor networks and monitoring systems. Additionally, renewable energy systems, including solar inverters and wind turbine controllers, depend on these reliable voltage regulators. Industrial ldo supplier offerings also extend to custom solutions tailored for specific applications, providing engineering support and technical consultation to ensure optimal performance in challenging industrial environments where standard commercial components may fail.