insulated gate bipolar transistor supplier

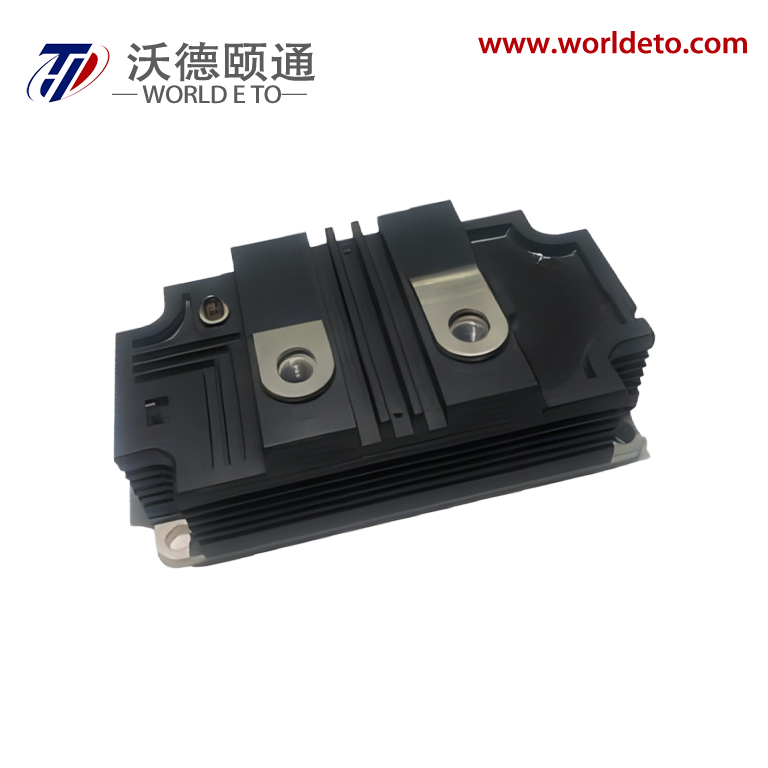

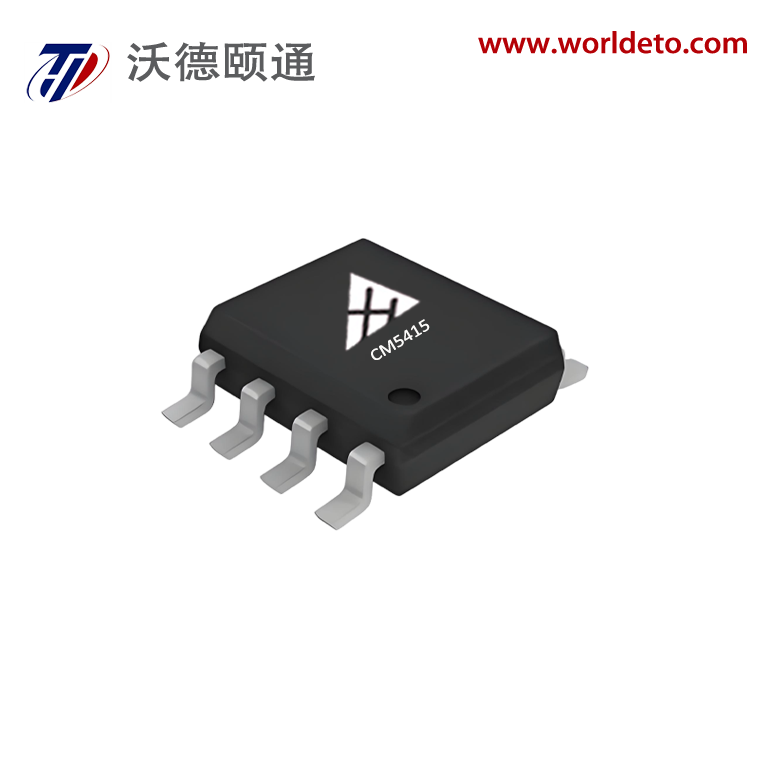

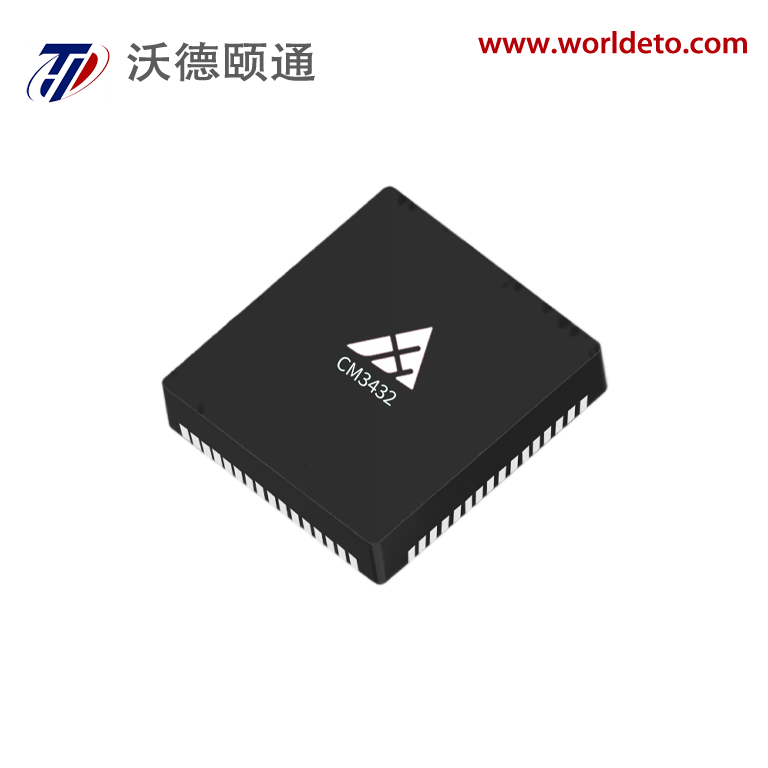

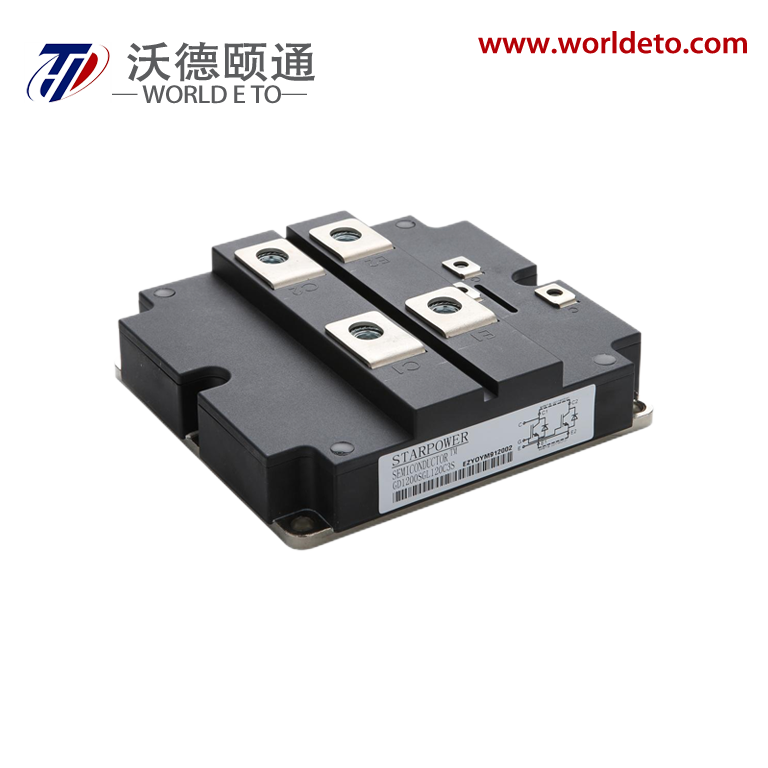

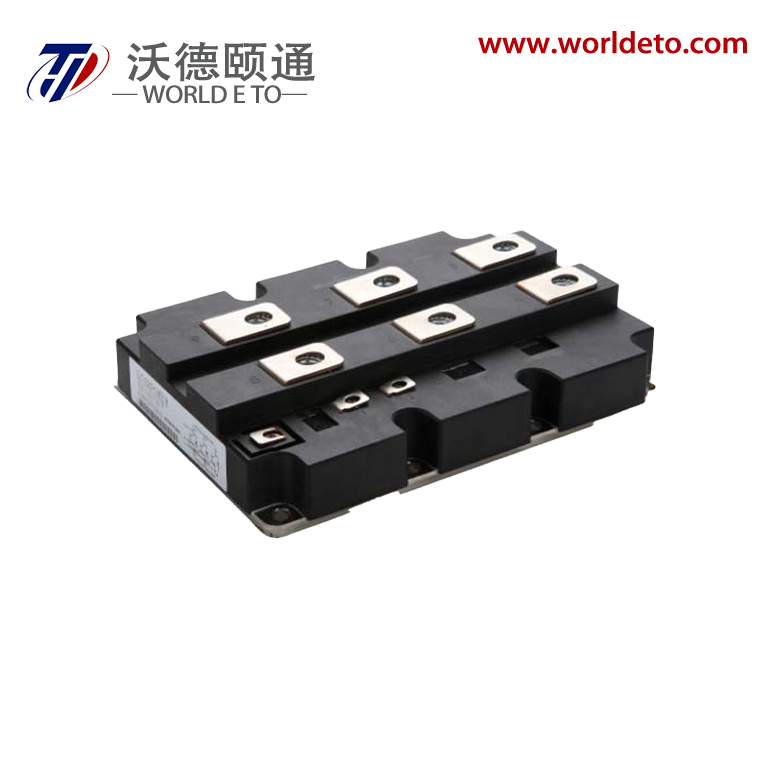

An insulated gate bipolar transistor supplier serves as a critical bridge between semiconductor manufacturers and industries requiring high-performance power switching solutions. These specialized suppliers provide IGBT modules and discrete components that combine the best characteristics of both MOSFET and bipolar junction transistors, delivering superior switching capabilities with enhanced efficiency. The insulated gate bipolar transistor supplier maintains comprehensive inventories of various IGBT configurations, including single switches, half-bridge modules, full-bridge assemblies, and intelligent power modules designed for diverse voltage and current ratings. Modern insulated gate bipolar transistor suppliers focus on delivering components with advanced technological features such as low conduction losses, fast switching speeds, and robust thermal management capabilities. These suppliers typically offer IGBTs with voltage ratings ranging from 600V to 6500V and current capacities extending from several amperes to thousands of amperes, catering to applications spanning from consumer electronics to industrial automation. The technological landscape of insulated gate bipolar transistor suppliers encompasses cutting-edge developments including silicon carbide enhancement, improved gate drive compatibility, and optimized chip designs that reduce electromagnetic interference. Primary applications served by insulated gate bipolar transistor suppliers include motor drives for industrial machinery, renewable energy systems such as solar inverters and wind power converters, electric vehicle powertrains, uninterruptible power supplies, welding equipment, and high-frequency switching power supplies. These suppliers maintain stringent quality control processes, ensuring that every IGBT component meets international standards for reliability, thermal performance, and electrical specifications. Furthermore, leading insulated gate bipolar transistor suppliers provide comprehensive technical support, including application engineering assistance, thermal modeling guidance, and circuit design optimization to help customers achieve optimal performance in their specific applications.