power diode chip

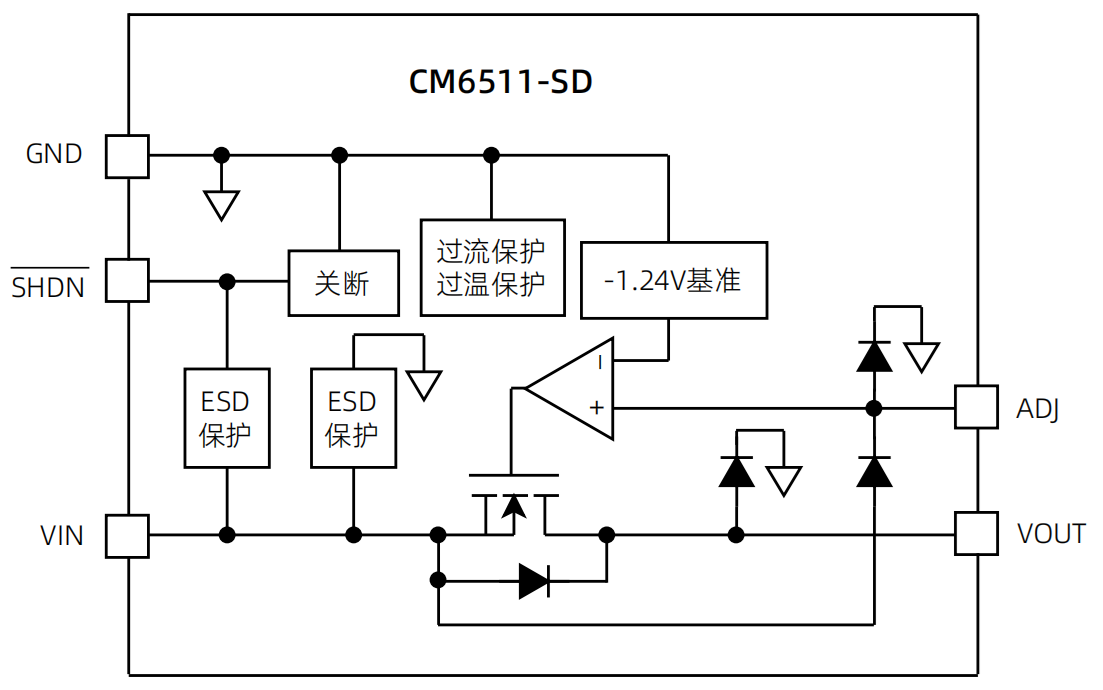

A power diode chip represents a fundamental semiconductor component designed to control electrical current flow in high-power electronic systems. This specialized device operates on the basic principle of allowing current to flow in one direction while blocking it in the reverse direction, making it essential for power conversion and electrical protection applications. The power diode chip consists of a PN junction fabricated using advanced semiconductor materials, typically silicon or silicon carbide, which determines its electrical characteristics and performance capabilities. Modern power diode chip designs incorporate sophisticated manufacturing techniques that enable them to handle substantial voltage levels and current densities while maintaining reliable operation under demanding conditions. The core functionality revolves around rectification, where alternating current gets converted to direct current, and voltage regulation, where excessive electrical surges are prevented from damaging sensitive components. These chips feature robust construction with enhanced thermal management properties, allowing them to dissipate heat effectively during high-power operations. The technological architecture includes optimized doping profiles and junction geometries that minimize forward voltage drop while maximizing reverse breakdown voltage ratings. Power diode chips find extensive use in power supplies, motor drives, renewable energy systems, automotive electronics, and industrial automation equipment. Their compact form factor enables integration into space-constrained applications without compromising performance. The manufacturing process involves precise control of semiconductor properties, resulting in devices with predictable electrical characteristics and long operational lifespans. Quality power diode chip designs incorporate protection features against overcurrent, overvoltage, and thermal stress conditions. These components serve as critical building blocks in power electronic circuits, enabling efficient energy conversion and system protection across diverse applications ranging from consumer electronics to heavy industrial machinery.