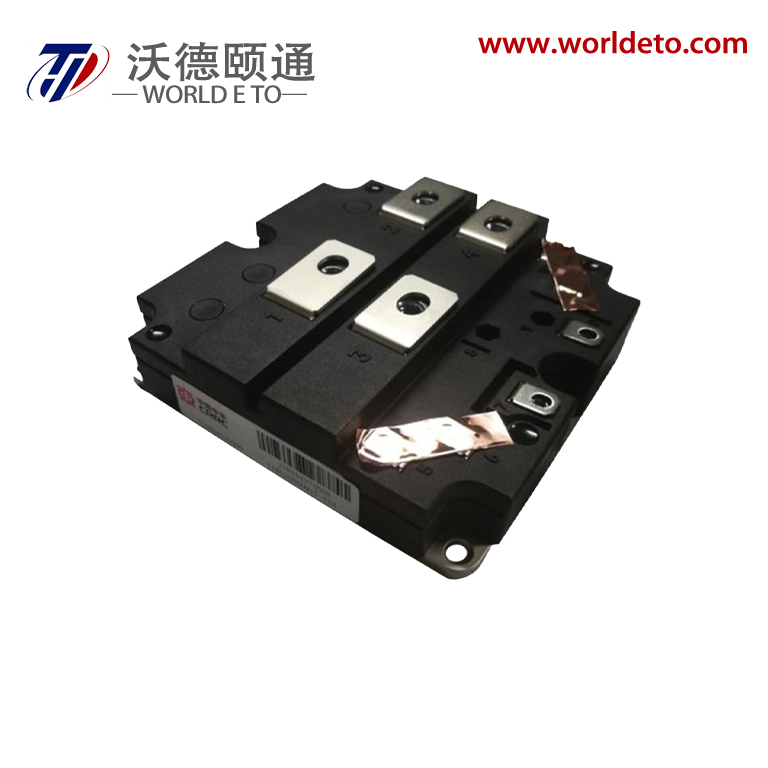

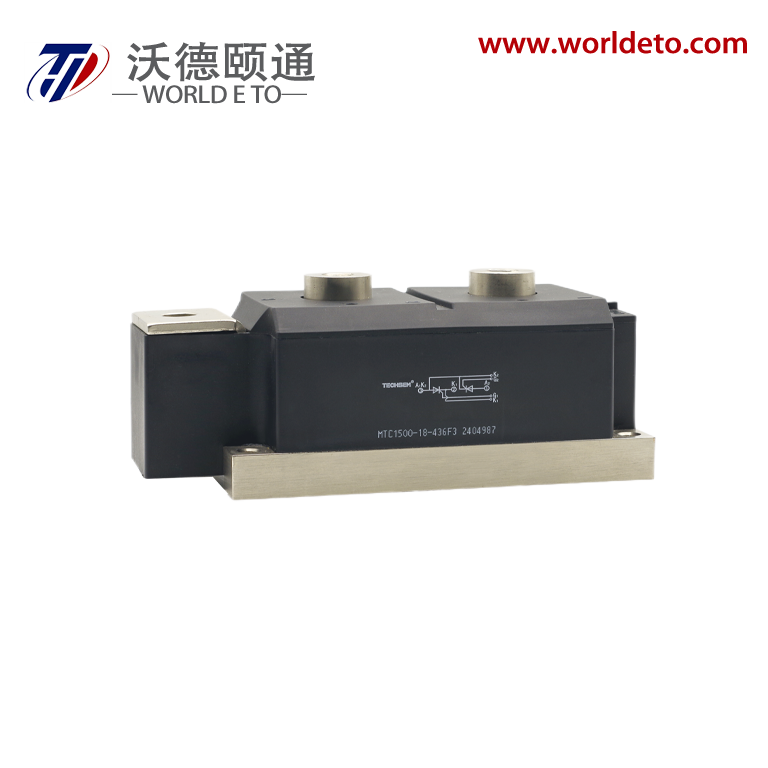

industrial transistor

Industrial transistors represent the backbone of modern electronic systems, serving as essential semiconductor devices that control electrical current flow in demanding manufacturing and automation environments. These robust electronic components function primarily as switches and amplifiers, enabling precise control of electrical signals in industrial machinery, power systems, and control circuits. The industrial transistor operates by using a small input signal to control a much larger output current, making it invaluable for signal processing and power management applications. Built specifically for harsh industrial conditions, these transistors feature enhanced durability compared to standard consumer-grade components. They incorporate advanced semiconductor materials such as silicon carbide and gallium arsenide, which provide superior performance under extreme temperatures, vibrations, and electromagnetic interference. The technological architecture of industrial transistors includes reinforced packaging, extended temperature ranges typically from -40°C to +150°C, and improved thermal management systems. Modern industrial transistor designs utilize sophisticated manufacturing processes that ensure consistent performance and reliability over extended operational periods. These devices come in various configurations including bipolar junction transistors (BJT), field-effect transistors (FET), and insulated-gate bipolar transistors (IGBT), each optimized for specific industrial applications. The applications span across multiple sectors including automotive manufacturing, aerospace systems, renewable energy installations, industrial automation, motor drives, power supplies, and process control systems. In manufacturing facilities, industrial transistors enable precise control of robotic systems, conveyor belts, and assembly line equipment. They play crucial roles in power conversion systems, helping transform electrical energy efficiently while maintaining strict safety standards required in industrial environments.