The Role of IGBT Modules in Industrial Power Systems

Importance of IGBT Modules in Modern Industrial Applications

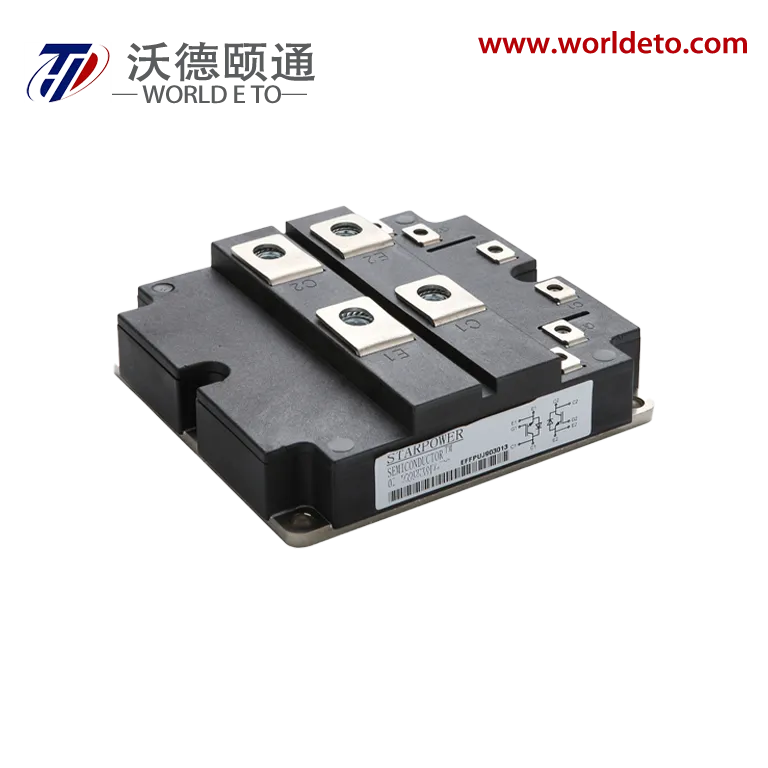

IGBT modules, or Insulated Gate Bipolar Transistors, play a key role in modern industrial power systems because they make power conversion and management much more efficient. What makes these components so valuable is their ability to boost system reliability through fast switching speeds while cutting down on power losses. This results in better overall energy efficiency across the board. We see them working hard in various industrial settings including motor drives, solar and wind energy installations, and those backup power systems known as UPS units. Take motor drives specifically. The quick switching action combined with minimal conduction losses means operators get precise control over operations and face less heat buildup in equipment. This not only extends the life of machinery but also keeps performance levels consistently high over time.

Industry data shows IGBT modules are really important for pushing forward sustainable tech developments. They help convert power efficiently which makes it possible to actually use renewable sources such as wind farms and solar panels effectively. When there's less energy lost during these conversions, it helps move us all toward cleaner energy systems worldwide. We're seeing this happen across many different areas right now, from old established industries to completely new markets emerging. No wonder then why IGBT modules have become so central to how modern manufacturing and energy production is evolving today.

Benefits of Parallel IGBT Module Configuration

Enhanced Power Capacity with Parallel IGBT Modules

When IGBT modules are set up in parallel, they boost the power handling capability of industrial systems quite a bit, allowing these systems to handle bigger loads without breaking a sweat. If one module goes down for whatever reason, the rest just keep going as normal so there's no major disruption to operations. From what we've seen in practice, spreading out the workload across multiple modules actually puts less strain on each one individually, meaning they tend to last longer before needing replacement. Manufacturing plants and processing facilities really benefit from this setup since their equipment needs constant power supply with minimal downtime. These industries can't afford power interruptions during production runs, so having redundant modules makes all the difference in keeping things running smoothly day after day.

Improved Efficiency Through Load Distribution

Parallel IGBT modules work really well at spreading out electrical loads evenly across multiple units. This helps prevent hotspots that could lead to module failures or system shutdowns. When loads are shared properly between modules, each one stays cooler and works better over time, which means the whole system runs more efficiently. Some real world tests show these balanced setups can cut down on power bills by around 15% in big manufacturing plants. For plant managers looking to save money while still meeting green standards, this kind of load management makes good business sense. It keeps operations running smoothly day after day without breaking the bank on electricity costs.

How Parallel IGBT Modules Work: Principles and Implementation

Load Distribution and Current Balancing Techniques

For parallel IGBT modules to work at their best, they need good load sharing and current balance techniques. The main approaches here are what we call active and passive balancing methods. These help spread out the current so it doesn't concentrate too much in one module. When everything shares the workload properly, no single part gets overloaded, and this reduces how fast different components wear down over time. Systems running with better load sharing tend to perform around 10 percent better overall. Getting this right matters a lot for keeping high power systems reliable and making them last longer without constant maintenance issues.

Voltage Synchronization and Gate Resistor Optimization

Getting the voltage levels synced up across parallel IGBT modules keeps the whole system stable and stops those annoying oscillations from happening. When it comes to gate resistors, getting their values right makes a big difference in how well each IGBT switches on and off. Picking the right resistance doesn't just cut down on energy loss during switching, it actually makes everything run much smoother day to day. From what we've seen in practice, fine tuning these resistor values really pays off in terms of making systems last longer between breakdowns and fixing problems. The better designed these parts are, the more efficient the whole setup becomes, which means less downtime and happier engineers dealing with IGBT installations. Good electrical design just matters a lot when working with these power modules.

Thermal Management in Parallel IGBT Systems

Good thermal control matters a lot when it comes to keeping parallel IGBT setups running smoothly over time. When we talk about solutions, things like proper heat sinks, active cooling methods, and regular temperature checks really help stop those modules from getting too hot. Studies have shown that when companies take care of their thermal management properly, they can maintain safe operating temps and actually see around a 20% improvement in system efficiency. But this isn't just about making components last longer. These practices ensure continuous operation without unexpected shutdowns, which means less downtime and better safety compliance in factories and plants where these systems are deployed daily.

Applications of Parallel IGBT Modules in Industrial Settings

High-Capacity Power Grids and Renewable Energy Systems

Parallel IGBT modules have become essential components when connecting renewable energy systems to large power grids, maintaining system stability while improving overall efficiency rates. These modules help convert electricity generated by solar panels and wind turbines into stable power supply that doesn't cause voltage spikes or dips in the grid. As countries around the world push harder for cleaner energy alternatives, this kind of flexibility becomes increasingly important for modern infrastructure. According to engineers working in the field, many power companies depend heavily on these semiconductor devices to keep their grids running smoothly despite changing weather conditions and variable production levels from different green energy installations scattered across various geographical locations.

Industrial Motor Drives and High-Power Inverters

For industrial motor drives dealing with heavy loads, parallel IGBT modules play a key role in handling those high current flows, which ultimately makes operations run smoother and more efficiently. These modules also work hand in hand with high power inverters that do the job of converting DC to AC power effectively across many different manufacturing environments. When companies install these types of modules, they typically see energy savings somewhere between 10% to 30% depending on what kind of industrial application we're talking about, and this naturally leads to better overall productivity numbers. Looking ahead, it seems pretty clear that IGBT technology adoption is going to keep growing in factories and plants worldwide as manufacturers push harder for ways to cut costs while still maintaining top notch performance standards.

Challenges in Parallel IGBT Module Deployment

Managing Current Imbalance and Oscillation Risks

Current imbalance remains one of the biggest headaches when working with parallel IGBT modules because it really cuts down on both efficiency and reliability. Studies indicate that if left unchecked, these imbalances could knock performance down by around 25%, which is no small number for industrial applications. To combat this issue, engineers need to implement solid feedback control systems that help prevent those annoying oscillations during normal operations. Keeping a close eye on things through regular monitoring combined with good diagnostic practices makes all the difference. Most experienced technicians will tell you that weekly system inspections along with smart diagnostic tools make parallel IGBT modules much more reliable while protecting against those pesky oscillation problems that can bring everything to a grinding halt.

Thermal Stress Mitigation Strategies

Getting rid of thermal stress matters a lot when it comes to making parallel IGBT modules last longer and work better overall. Cooling methods such as air circulation fans or liquid based systems play a key role in keeping things at the right temperature inside these modules. Studies show that poor thermal management can actually increase module failures by over 30 percent, which makes good heat control really important for anyone working with this tech. Businesses that spend money on better cooling solutions tend to see their equipment perform better while spending less on maintenance down the road. Beyond just preventing damage from heat buildup, proper thermal management helps maintain efficient operations over time. When companies implement these cooling approaches, they find their IGBT modules handle different industrial situations much more reliably without breaking down unexpectedly.

Conclusion â Key Considerations for Optimizing Parallel IGBT Module Use in Industry

Getting the most out of parallel IGBT modules requires attention to several critical aspects. Current imbalance management stands at the top of the priority list, followed closely by reducing oscillation risks that could destabilize the entire system. Thermal stress remains another major concern for long term stability. When manufacturers implement sophisticated control systems alongside proper cooling solutions, they not only boost reliability but also significantly prolong the life expectancy of these modules. Industrial facilities benefit greatly from this approach since stable operation translates directly into reduced downtime and maintenance costs across their production lines.

FAQs

What are IGBT modules mainly used for in industrial systems?

IGBT modules are primarily used for efficient power conversion and management in industrial systems, including applications like motor drives, renewable energy systems, and UPS.

How do parallel IGBT modules improve efficiency?

Parallel IGBT modules improve efficiency by enhancing power capacity, ensuring reliable power solutions, and optimally distributing loads to reduce risks of overheating and component failure.

What are the key challenges of deploying parallel IGBT modules?

The main challenges include managing current imbalance and oscillation risks, as well as mitigating thermal stress to prolong the lifespan of the modules.

Table of Contents

- The Role of IGBT Modules in Industrial Power Systems

- Benefits of Parallel IGBT Module Configuration

- How Parallel IGBT Modules Work: Principles and Implementation

- Applications of Parallel IGBT Modules in Industrial Settings

- Challenges in Parallel IGBT Module Deployment

- Conclusion – Key Considerations for Optimizing Parallel IGBT Module Use in Industry

- FAQs