Introduction to IGBT Modules in Electric Welding Machines

What Are IGBT Modules?

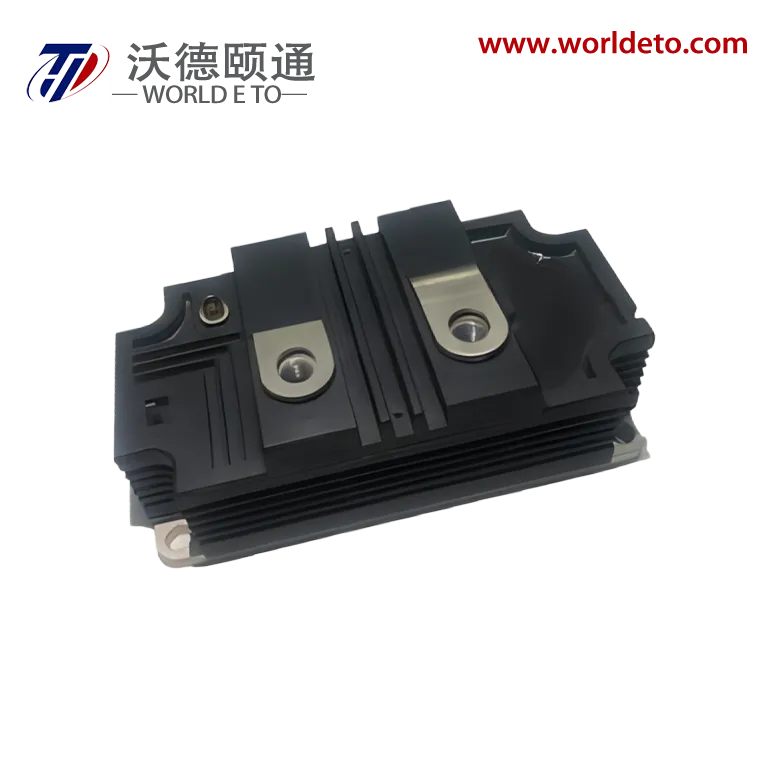

IGBT modules, which stands for Insulated Gate Bipolar Transistors, combine features from both MOSFETs and BJTs to give better power switching performance. They play a big role in modern electric welding equipment where precise control during the welding process matters a lot. What makes these modules so important is how well they handle large amounts of current and voltage without breaking down, which is why many manufacturers rely on them for industrial welding tasks that need both accuracy and efficiency. The improvements we've seen with IGBT technology mean welders can work faster while still getting good results, something that has made these components pretty much standard in most welding setups today.

The Evolution of Welding Machine Technology

Welding tech has come a long way from those old-school methods we all know and love. Digital controls now dominate the scene, thanks mostly to improvements in semiconductor tech over recent years. IGBT modules stand out as game changers here, really pushing welding into a new era of efficiency and reliability. Looking back at how things have changed, it's clear that most modern industrial welding setups these days rely on IGBT modules. Why? Because they let operators automate processes better while getting much finer control over weld quality. Factories across manufacturing sectors have seen dramatic improvements in production speed and consistency since switching to these modules. The whole point is making sure welds meet exact specifications every single time, which saves money and reduces waste in the long run.

Why IGBT Modules Are Critical for Modern Welding

IGBT modules are becoming increasingly important in modern welding because they boost process efficiency thanks to faster switching speeds and better control precision. These modules also cut down on operating expenses since they save energy and reduce equipment downtime due to their reliable performance. Industry data suggests that when welders switch to IGBT technology, energy consumption drops by roughly 30%, making these modules both eco friendly and budget smart choices for shops looking to modernize. Many manufacturers are now incorporating IGBT systems into their welding setups as part of broader efforts to cut energy waste and shrink carbon footprints across factory floors.

How IGBT Modules Improve Welding Efficiency

High Switching Frequency for Reduced Energy Loss

IGBT modules have really high switching frequencies, often hitting several thousand cycles per second. This actually cuts down on energy losses when they're running. The fast switching speeds mean welders get quicker responses and better control during their work, which makes everything run smoother. Some research indicates that swapping out old tech for IGBTs can cut energy waste by around half compared to what was used before. For shops looking at sustainability, this matters a lot because it means throwing away less power and getting more bang for their buck in actual welding tasks rather than just heating up the air around them.

Precision Control of Welding Current

IGBT modules give much better control of welding current, making it possible to adjust for different types of welding jobs and materials being worked on. Better control means cleaner, more consistent welds across the board something that matters a lot when working on projects where accuracy counts. Real world testing shows manufacturers who switch to IGBT tech tend to see lower defect rates and generally better quality welds coming out of their operations. When welders can manage current so precisely, the whole process becomes more dependable too there are fewer mistakes happening during production runs, and shops actually get more done in less time without sacrificing quality standards.

Optimized Power Conversion for Lower Heat Generation

IGBT module designs help achieve better power conversion while generating much less heat during welding operations. The reduced thermal stress keeps critical components intact and improves how well these systems actually perform day to day. Field tests show welding equipment with modern IGBT tech runs around 20 degrees cooler compared to older models with standard power components. Cooler operating temps mean these machines last longer between breakdowns and generally need fewer repairs throughout their service life. For shop owners concerned about downtime costs, this temperature advantage translates directly into real savings on both parts and labor expenses.

For more details about these benefits, check out the comprehensive specifications of the [IGBT Modules](YOUR_PRODUCT_DETAIL_LINK) we offer.

Enhanced Stability Through Advanced IGBT Technology

Consistent Output in High-Demand Applications

IGBT tech keeps the power flowing consistently, something that matters a lot for applications where reliability is key. When systems have stable power input, they run better without unexpected interruptions or quality drops. Studies looking at welding shops found that when machines get steady power, there's less variation between products coming off the line. The difference adds up over time. Manufacturers who switched to IGBT modules tell similar stories about their equipment running smoother day after day. For factories needing to keep production going nonstop, this kind of stability makes all the difference in maintaining good output rates without constant maintenance headaches.

Adaptive Feedback Systems for Arc Stability

Welding machines with IGBT technology now come with adaptive feedback systems that tweak settings on their own to keep the arc stable during operation. The result? Better control throughout the whole welding process which means stronger welds that hold up under stress. Industry pros have seen time and again how critical arc stability really is for making durable welds that last. When arcs stay steady, the weld quality improves significantly, and interestingly enough, it actually makes the equipment itself last longer too. These machines perform consistently whether working on thin sheet metal or thick structural steel, something that traditional welders struggle with when conditions change mid-job.

Mitigating Voltage Fluctuations

IGBT modules help control those pesky voltage spikes that would normally mess up the welding process, giving welders a much steadier output when they need it most. When voltage stays consistent throughout the operation, the whole system just runs better and lasts longer without breaking down so often. Industry reports show that welding setups with IGBT tech cut down on voltage issues around 70 percent compared to what was used before this technology came along. For shops working in places where power supply isn't always reliable, having this kind of stability makes all the difference between getting good welds and dealing with constant equipment problems.

Key Benefits of IGBT Modules in Welding Applications

Higher Duty Cycles for Continuous Operation

IGBT modules make it possible for welding machines to handle longer duty cycles without getting too hot to run safely. This feature really matters in tough environments like auto shops and construction sites where stopping isn't an option when work needs to get done. These modules let equipment take the heat over extended periods, which means factories can keep producing parts without slowdowns during busy times. Some tests show that welders with IGBT tech actually perform around 60 percent better when pushed hard, something plant managers notice immediately because their production lines just keep moving instead of stalling out mid-job.

Improved Arc Control for Precision Welding

IGBT modules bring a whole new level of control to arc management during welding operations, allowing welders to make much more precise adjustments throughout the process. When dealing with stuff like sheet metal or other thin materials, this kind of fine control makes all the difference in getting good results without damaging what's being worked on. Weld shops report better outcomes overall with stronger bonds between metals and fewer rework requests from clients. Industry publications keep pointing out how important proper arc control really is, often listing it among top factors that separate successful welding companies from those struggling to maintain their market position and client base.

Extended Equipment Lifespan

IGBT modules offer real benefits when it comes to making welding equipment last longer. They help manage heat better and put less strain on the machine during operation. The result? Components don't wear out as fast, which means mechanics spend less time fixing things and shops can go months without needing major repairs. Some industry data suggests machines with IGBT tech tend to stick around about 30% longer than those using older methods. For shop owners, this translates into real money saved over time while keeping their gear running smoothly and reliably through countless weld jobs.

IGBT modules are integral to modern welding operations, providing the technological framework necessary for enhancing operational efficiency and equipment longevity.

Conclusion â The Future Impact of IGBT Modules in Welding Technology

IGBT technology keeps advancing, and we're starting to see it make its way into welding gear, bringing about real improvements in how these machines work. What makes IGBT modules stand out? They can handle those high voltage switches at super fast speeds while losing very little power along the way. That's why they fit so well inside electric welders today. Looking at what this means practically, welders aren't just getting better performance from their equipment anymore either. The money saved on electricity bills plus less downtime for repairs adds up over time. Manufacturers continue improving these modules all the time too. Better cooling solutions and smarter materials mean welders will likely get even tougher and more efficient machines in coming years. Industries that rely heavily on metal joining processes are already feeling the impact of these changes across factories worldwide.

FAQ

What are IGBT modules used for?

IGBT modules are used in electric welding machines for enhanced power switching capabilities. They help control the welding process precisely, manage high currents and voltages, and are crucial in industrial applications requiring precision and efficiency.

Why are IGBT modules important in modern welding?

IGBT modules increase the efficiency of welding processes through faster switching, higher precision, reduced energy consumption, and improved reliability. They also help reduce operational costs and align with the trend toward energy efficiency.

How do IGBT modules improve welding machine efficiency?

By providing high switching frequencies, precision control over welding current, and optimized power conversion, IGBT modules reduce energy loss, minimize heat generation, and enhance the overall efficiency of welding operations.

What challenges are associated with implementing IGBT modules?

Challenges include thermal management in high-power environments, ensuring reliability under heavy loads, and aligning cooling system advancements with material design improvements. Solutions involve effective cooling methods and robust testing to enhance reliability and performance.