Brief introduction

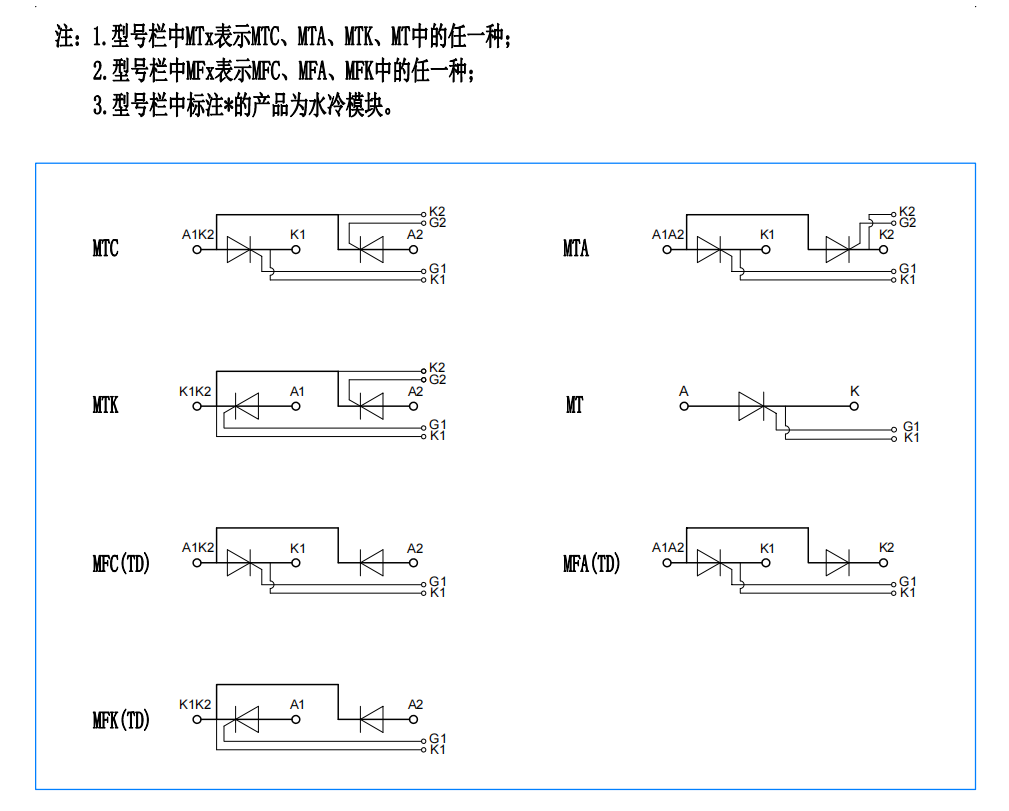

Thyristor/Diode Module, MTx1200 MFx1200 MT1200,Water cooling,produced by TECHSEM .1200A.Widely used in various rectifiers and DC power supplies for PWM inverters

| VRRM,VDRM |

Type & Outline |

600V

800V

1000V

1200V

1400V

1600V

1800V

1800V

|

MDx1200-06-411F3

MDx1200-08-411F3

MDx1200-10-411F3

MDx1200-12-411F3

MDx1200-14-411F3

MDx1200-16-411F3

MDx1200-18-411F3

MD1200-18-411F3G

|

MDx stands for any type of MDC, MDA, MDK

Features

- Isolated mounting base 3000V~

- Pressure contact technology with

- Increased power cycling capability

- Space and weight saving

Typical Applications

- AC/DC Motor drives

- Various rectifiers

- DC supply for PWM inverte

|

SYMBOL

|

CHARACTERISTIC

|

TEST CONDITIONS

|

Tj(℃) |

VALUE |

UNIT

|

Min |

Type |

Max |

IT(AV) |

Mean on-state current |

180°half sine wave 50Hz

Single side cooled, THS=55℃

|

125

|

|

|

1200 |

A |

IT(RMS) |

RMS on-state current |

|

|

1884 |

A |

IDRM IRRM |

Repetitive peak current |

at VDRM at VRRM |

125 |

|

|

55 |

mA |

ITSM |

Surge on-state current |

VR=60%VRRM, t=10ms half sine |

125 |

|

|

26.0 |

kA |

I2t |

I2t for fusing coordination |

125 |

|

|

3380 |

103A2s |

VTO |

Threshold voltage |

|

125

|

|

|

0.83 |

V |

rT |

On-state slope resistance |

|

|

0.14 |

mΩ |

VTM |

Peak on-state voltage |

ITM=3000A |

25 |

|

|

1.88 |

V |

dv/dt |

Critical rate of rise of off-state voltage |

VDM=67%VDRM |

125 |

|

|

1000 |

V/μs |

di/dt |

Critical rate of rise of on-state current |

Gate source 1.5A

tr ≤0.5μs Repetitive

|

125 |

|

|

200 |

A/μs |

IGT |

Gate trigger current |

VA= 12V, IA= 1A

|

25

|

30 |

|

200 |

mA |

VGT |

Gate trigger voltage |

0.8 |

|

3.0 |

V |

IH |

Holding current |

10 |

|

200 |

mA |

IL |

Latching current |

|

|

1000 |

mA |

VGD |

Non-trigger gate voltage |

VDM=67%VDRM |

125 |

|

|

0.20 |

V |

Rth(j-c) |

Thermal resistance Junction to case |

Single side cooled per chip |

|

|

|

0.048 |

℃/W |

Rth(c-h) |

Thermal resistance case to heatsink |

Single side cooled per chip |

|

|

|

0.018 |

℃/W |

Viso |

Isolation voltage |

50Hz,R.M.S,t= 1min,Iiso:1mA(MAX) |

|

3000 |

|

|

V |

|

Fm

|

Terminal connection torque(M12) |

|

|

12 |

|

16 |

N·m |

Mounting torque(M8) |

|

|

10 |

|

12 |

N·m |

Tvj |

Junction temperature |

|

|

-40 |

|

125 |

℃ |

Tstg |

Stored temperature |

|

|

-40 |

|

125 |

℃ |

Wt |

Weight |

|

|

|

3230 |

|

g |

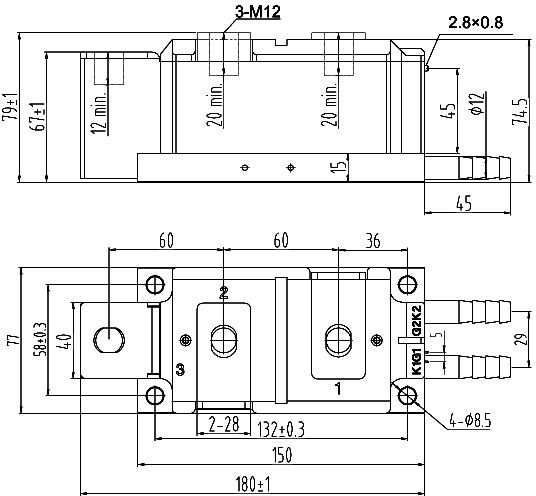

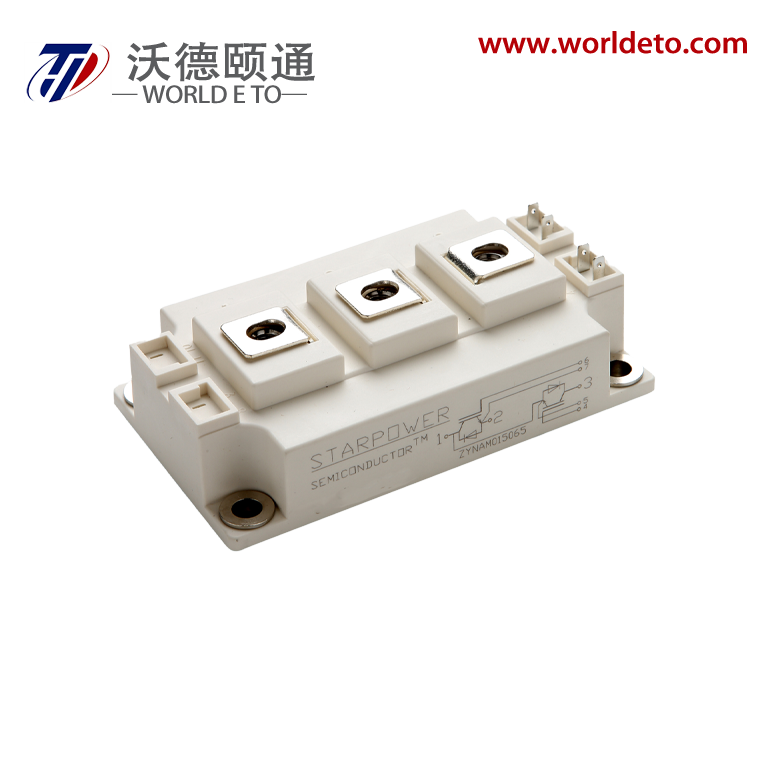

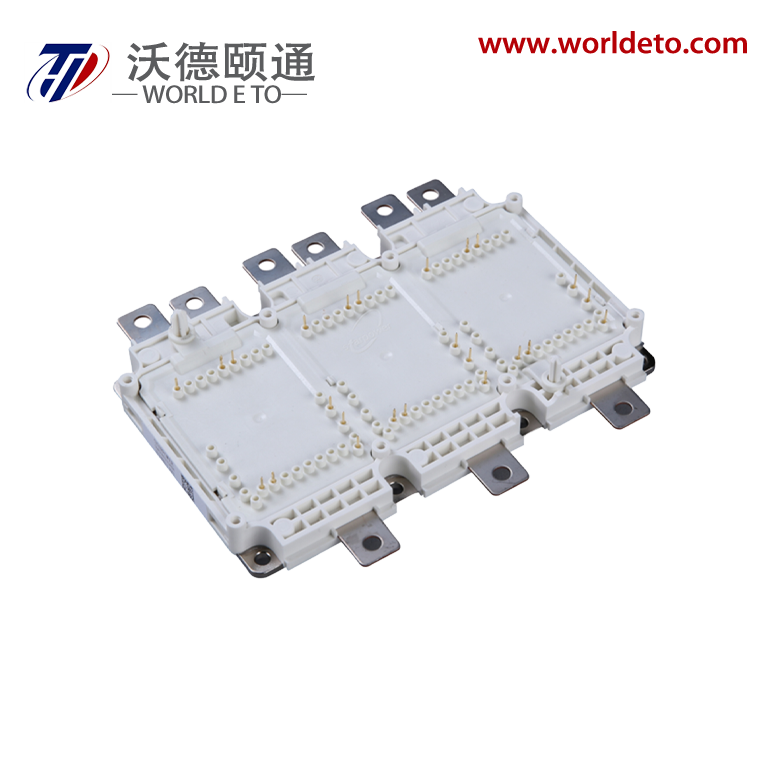

Outline |

411F3 |

Outline

Well-equipped laboratory

We have a well-equipped laboratory for testing and strictly control the quality of our products. This ensures that the qualification rate of the products we deliver to customers reaches 100%.

Automated modern factory

The modern automated factory ensures that all performance indicators of our products are highly consistent, minimizing the differences in each product's parameters as much as possible. This not only guarantees the reliability and consistency of our products but also serves as an important guarantee for the safe and reliable operation of our customers' equipment.

Adequate production capacity

The manufacturer's strong comprehensive strength and sufficient production capacity ensure timely delivery of every order.

Application Case

MTx1200 Rectifier Diode in PWM Inverter DC Power Supplies

1. Abstract

This case study details the successful implementation of the MTx1200 rectifier diode in the three-phase input stage of a high-power DC power supply for PWM (Pulse Width Modulation) inverters. The client, a manufacturer of industrial motor drives, required a robust and efficient solution to rectify AC mains voltage to a stable DC bus. The MTx1200 was selected for its superior current handling, low forward voltage drop, and excellent recovery characteristics, resulting in enhanced system efficiency, improved thermal performance, and increased overall reliability.

2. Application Background: PWM Inverter DC Power Supply

A PWM inverter drive controls the speed and torque of an AC motor. Its first critical stage is the DC power supply, which consists of:

A Rectifier Section: Converts incoming three-phase AC voltage to DC.

A DC Bus (Link): Capacitors smooth the rectified DC voltage and provide energy storage.

An Inverter Section: (Not covered here) Uses IGBTs to chop the DC bus voltage into a variable-frequency AC output for the motor.

The performance of the rectifier diodes directly impacts the entire system's efficiency, heat generation, and electrical noise.

Client's Challenge:

The client's existing 1000A DC power supply design using standard rectifiers was experiencing:

High Operational Temperatures: Leading to large heatsinks and active cooling requirements.

Efficiency Losses: Significant power loss (I²R and switching losses) at full load.

Voltage Ringing and EMI: Caused by slow reverse recovery, stressing other components.

3. The MTx1200 Solution

The MTx1200 was integrated into a three-phase bridge rectifier configuration.

Key MTx1200 Specifications Beneficial for This Application:

High Average Forward Current (I_F(AV)): 1200A. Provides a significant safety margin and handles surge currents effortlessly.

Low Forward Voltage Drop (V_F): Typically 0.97V at 600A. This is a primary source of efficiency gain, reducing conduction losses.

Fast Reverse Recovery Time (t_rr): < 250 ns. Minimizes switching losses and reduces electromagnetic interference (EMI), leading to a cleaner DC bus.

High Surge Current Capability (I_FSM): 30kA (half sine wave). Withstands harsh industrial power environments and start-up surges.

Isolated Package: The MTx package (TO-247 Plus) provides easy mounting to heatsinks and robust isolation, simplifying assembly and improving safety.

4. Implementation and Test Results

The client replaced the existing rectifiers with the MTx1200 diodes in their standard 1000A design. The system was tested under full load conditions.

Performance Comparison:

Parameter |

Previous Solution |

With MTx1200 |

Improvement |

Power Loss per Diode |

~970W |

~582W |

~40% Reduction |

Heatsink Temperature |

95°C |

72°C |

23°C Reduction |

Overall System Efficiency |

93.5% |

95.8% |

+2.3% Points |

DC Bus Voltage Overshoot |

Significant |

Minimal |

Improved Stability |

5. Conclusion and Value Proposition

The integration of the MTx1200 rectifier diode provided a compelling solution for the high-power PWM inverter DC supply.

Benefits Delivered to the End-Client:

Higher System Efficiency: Reduced power loss translates directly to lower operating costs, a critical selling point for end-users.

Improved Thermal Management: Lower operating temperatures allow for smaller heatsinks or reduced cooling needs, lowering system cost and increasing longevity.

Enhanced Reliability: The robust design of the MTx1200 and reduced thermal stress significantly improve the Mean Time Between Failures (MTBF) of the power supply.

Reduced EMI simplifies compliance with regulatory standards (e.g., IEC 61800-3).

USERS

Why choose us?

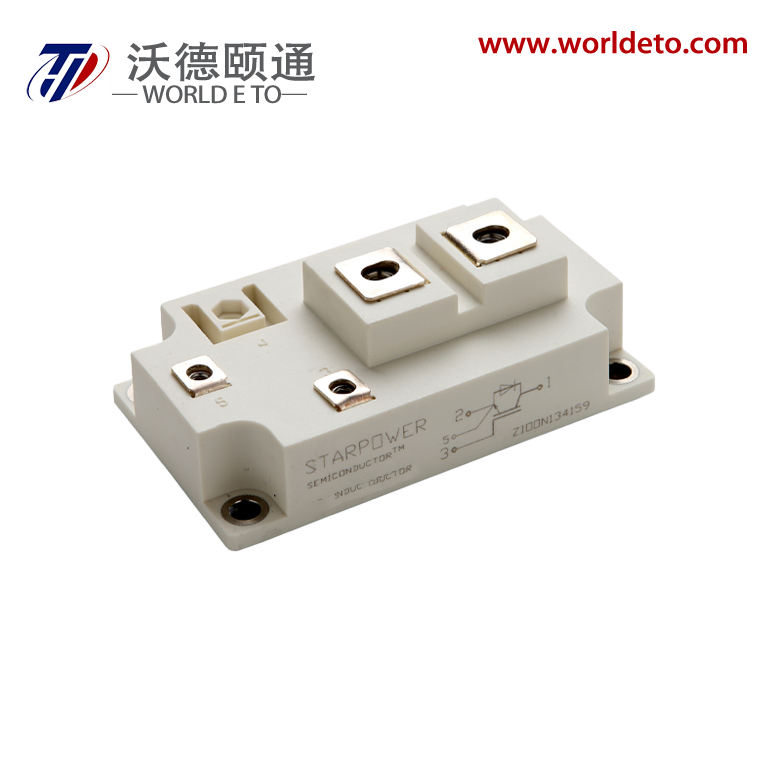

Beijing World E To Technology Co., Ltd. is leading supplier of semiconductor products like IGBT moudel,IGBT discretes, IGBT Chips ,ADC/DAC ,Thyristor in China, mainly engaged in the official distribution of the brand of CRRC, Starpower, Techsem NARI.With import and export qualifications and 11 years experience in this industry, we export to Russia, UAE, and many other Europe area.

We have strict requirements for the selection of manufacturers, professional technical teams, and product quality control Ensure the smooth operation of projects for customers in the fields of rail transit, power industry, electric vehicles, motor drive inverters, and frequency converters.

Meanwhile, helping customers customize various thyristors and power assemblies according to their special parameter requirements is another important component Our contract manufacturing and one of our advantages.

Safe delivery

We cooperate with top international freight companies to ensure timely transportation.

At the same time, we carefully package every batch of goods delivered to our customers according to their requirements to ensure that our goods are delivered intact and undamaged.