thyristor supplier

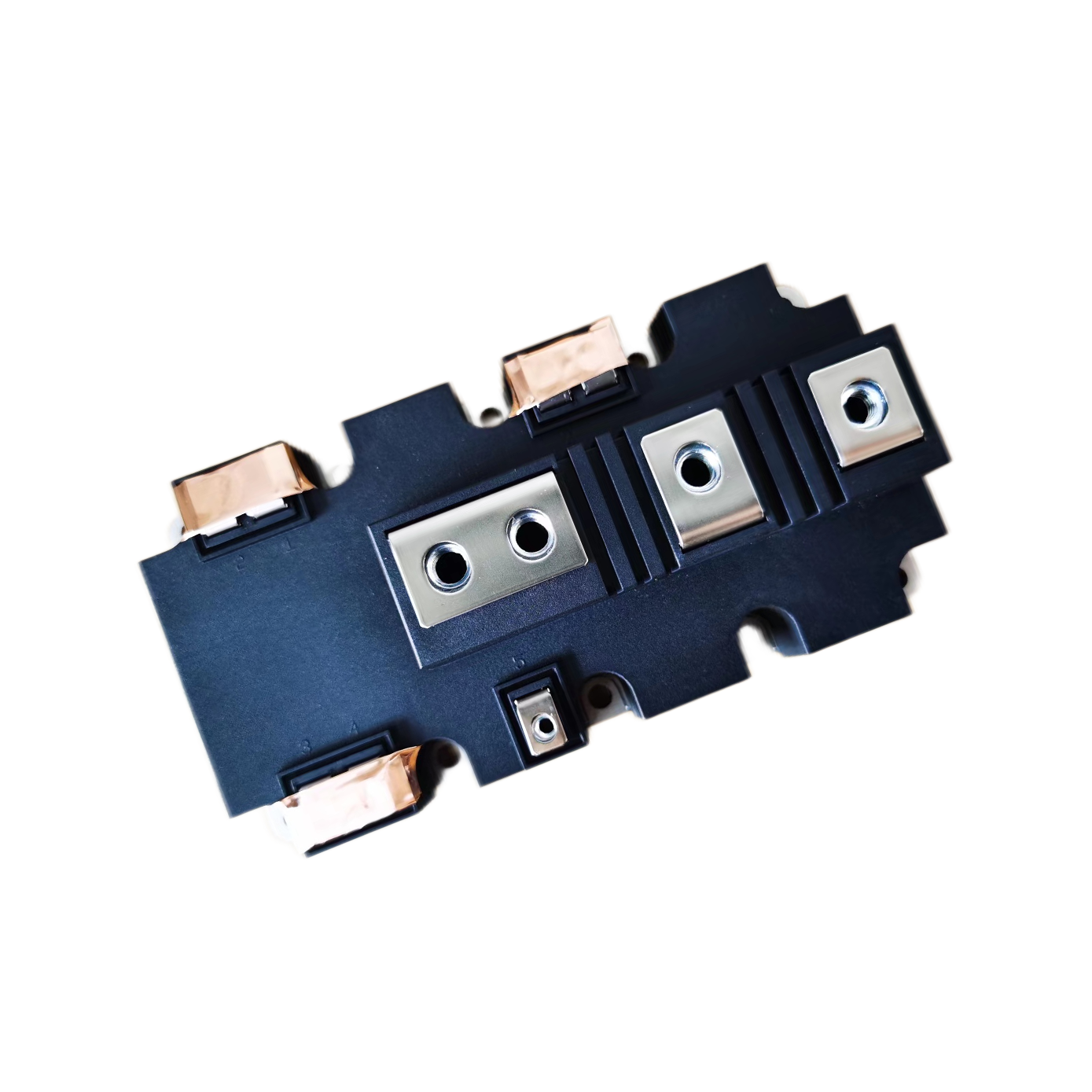

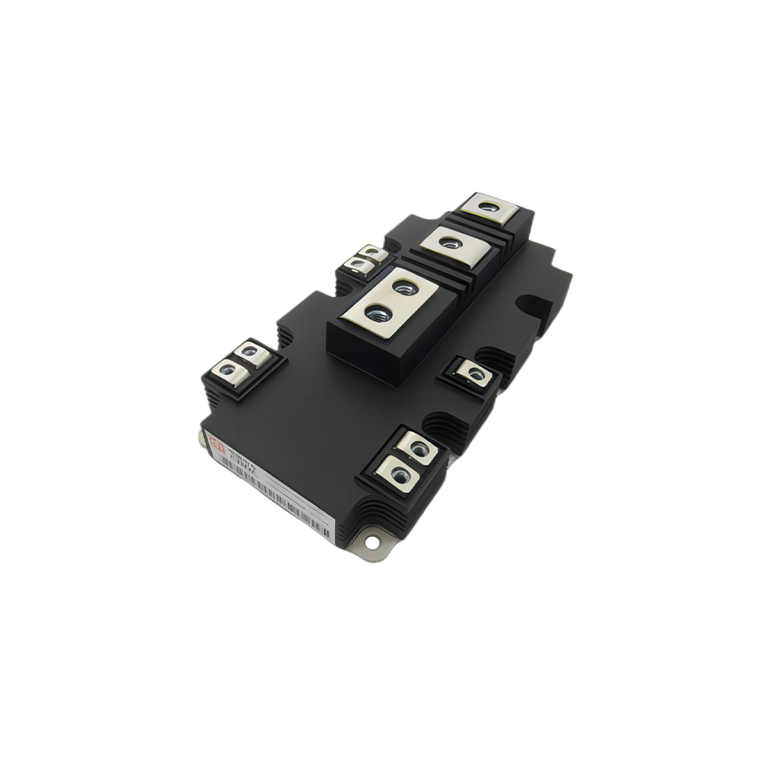

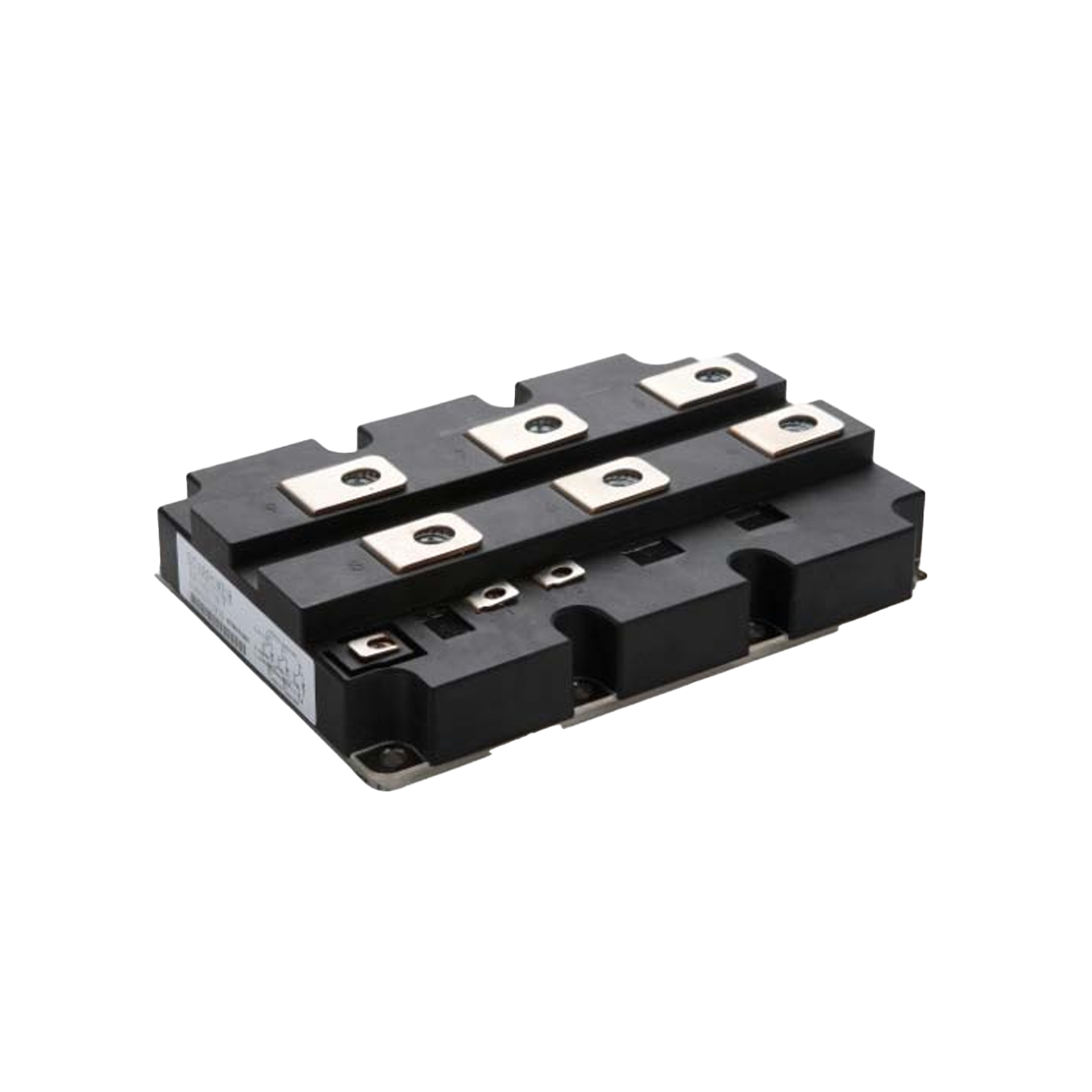

A thyristor supplier serves as a critical bridge between semiconductor manufacturers and industries requiring power control solutions. These specialized companies focus on distributing, customizing, and supporting thyristor devices that regulate electrical power flow in various applications. The primary function of a thyristor supplier involves sourcing high-quality semiconductor switches from established manufacturers and providing comprehensive technical support to ensure optimal implementation. Modern thyristor suppliers maintain extensive inventories of different thyristor types, including Silicon Controlled Rectifiers (SCRs), Gate Turn-Off thyristors (GTOs), and Integrated Gate Commutated Thyristors (IGCTs). Their technological expertise encompasses understanding voltage ratings, current capacities, switching frequencies, and thermal management requirements across diverse industrial sectors. These suppliers offer value-added services such as application engineering, custom packaging, and system integration support. The core technology behind thyristors involves controlled rectification, where these devices act as electronically controlled switches capable of handling substantial power loads while maintaining precise control over current flow. A professional thyristor supplier typically provides devices ranging from low-power applications in consumer electronics to high-power industrial systems managing thousands of amperes. Their technical knowledge extends to understanding gate triggering mechanisms, forward voltage drops, and holding current specifications essential for proper device selection. Applications span across motor drives, power supplies, lighting control systems, welding equipment, and renewable energy inverters. The supplier's role includes matching specific thyristor characteristics with customer requirements, ensuring proper heat sinking recommendations, and providing detailed datasheets for design engineers. Additionally, these suppliers often maintain relationships with multiple manufacturers, enabling them to offer competitive pricing and alternative solutions when primary options face supply constraints or technical limitations.