Cutting-Edge Packaging and Thermal Management Solutions

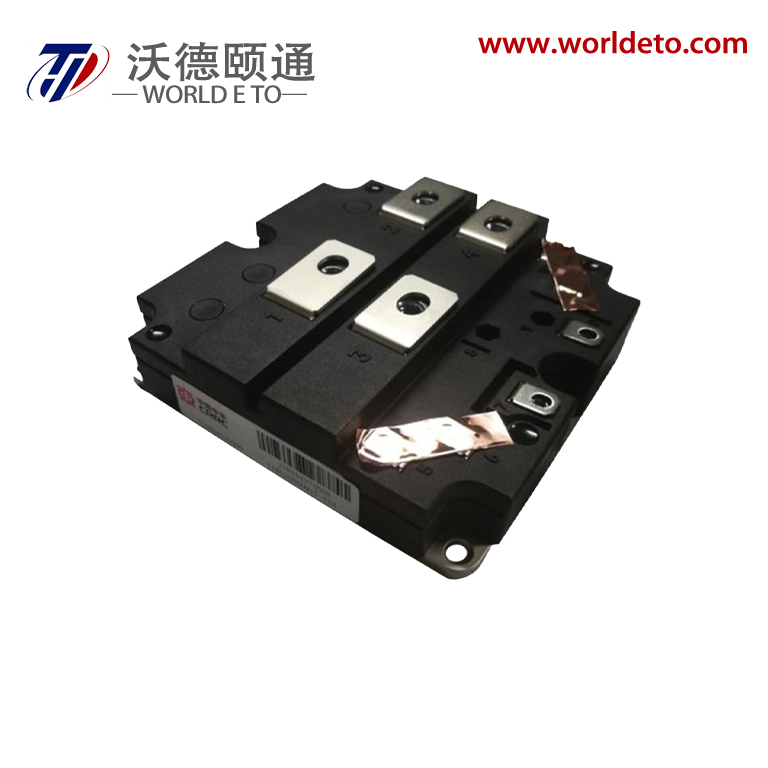

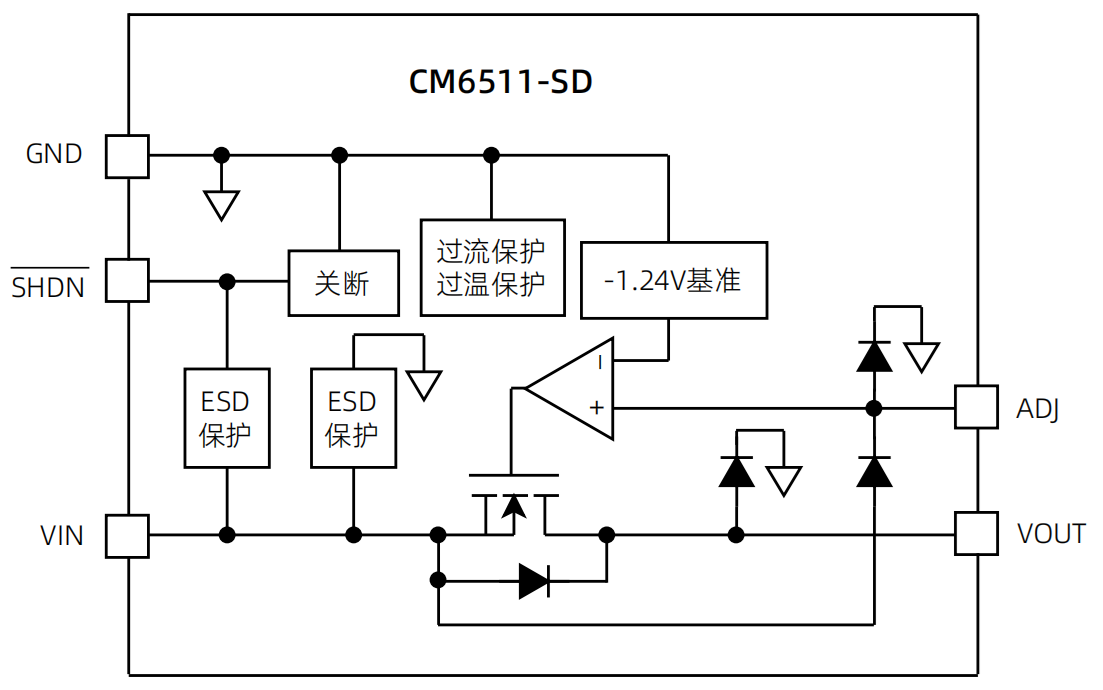

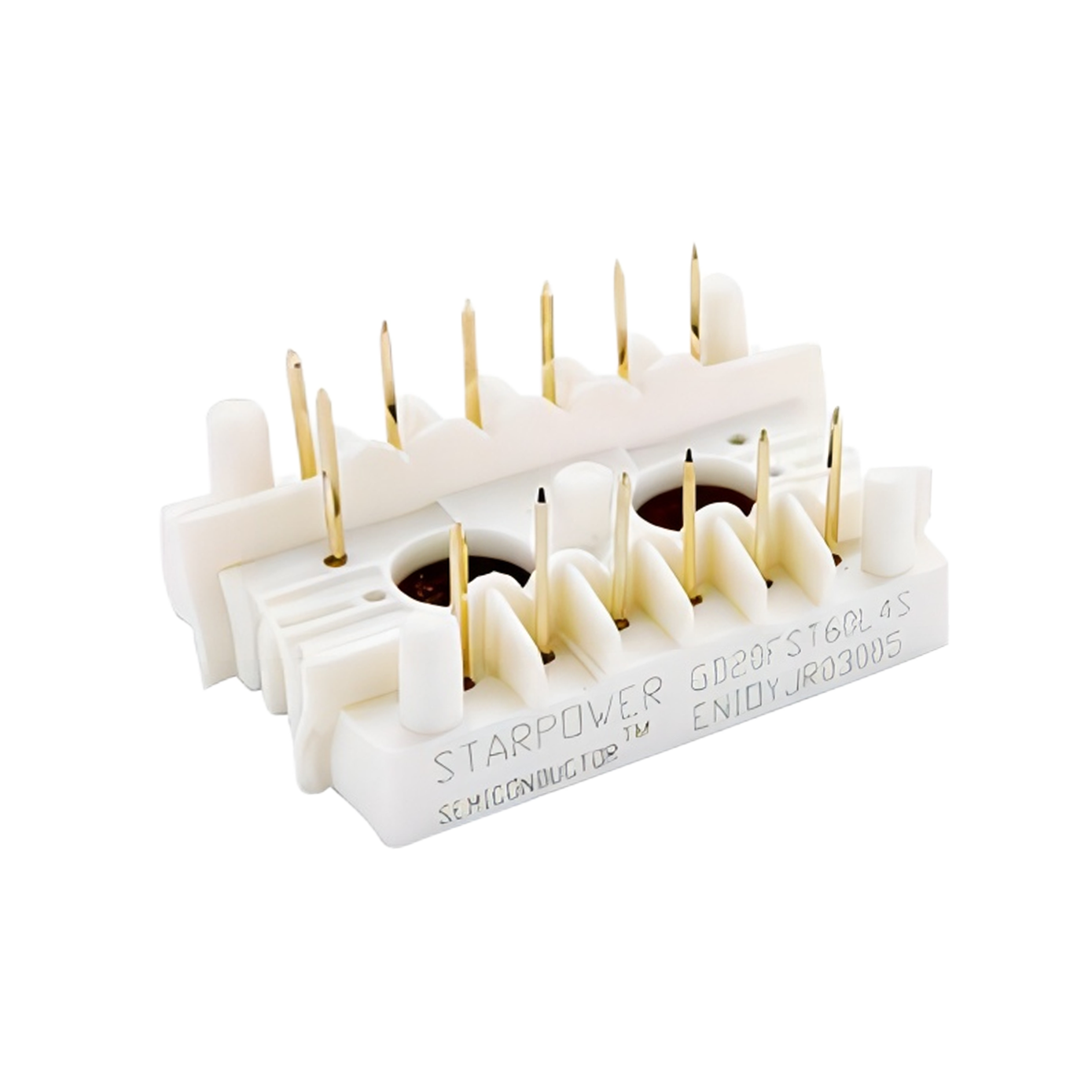

Industry-leading igbt chip suppliers distinguish themselves through cutting-edge packaging and thermal management solutions that maximize device performance, reliability, and integration flexibility for diverse applications. Advanced packaging technologies developed by innovative suppliers address critical challenges including thermal dissipation, electromagnetic interference, parasitic inductance reduction, and mechanical stress management. Modern packaging approaches incorporate sophisticated materials such as copper baseplates, aluminum nitride substrates, and advanced thermal interface materials that dramatically improve heat transfer capabilities and thermal cycling performance. Intelligent thermal design features implemented by professional igbt chip suppliers include optimized chip layouts, enhanced thermal paths, and integrated temperature monitoring capabilities that prevent overheating and extend device lifespans. Multi-chip modules developed by leading suppliers combine multiple IGBT dies with associated gate drivers, protection circuits, and current sensing elements within single packages, reducing system complexity and improving power density. Innovative packaging geometries such as press-pack designs, discrete modules, and custom form factors enable igbt chip suppliers to address specific customer requirements for space-constrained applications, high-power systems, and specialized mounting configurations. Advanced interconnection technologies including wire bonding alternatives, direct copper bonding, and sintering processes improve electrical performance, reduce parasitic effects, and enhance long-term reliability under demanding operating conditions. Environmental protection features incorporated into modern packaging solutions include moisture resistance, chemical compatibility, and vibration tolerance that ensure reliable operation in harsh industrial environments. Standardized packaging options provided by established igbt chip suppliers facilitate easy integration, replacement, and system upgrades while maintaining compatibility with existing infrastructure and design practices. Thermal simulation tools and design support services offered by comprehensive suppliers enable customers to optimize heat sink designs, cooling strategies, and thermal management systems for maximum performance and reliability. Quality testing protocols for packaging integrity include thermal cycling, power cycling, humidity exposure, and mechanical stress testing that verify long-term performance and reliability under real-world operating conditions.