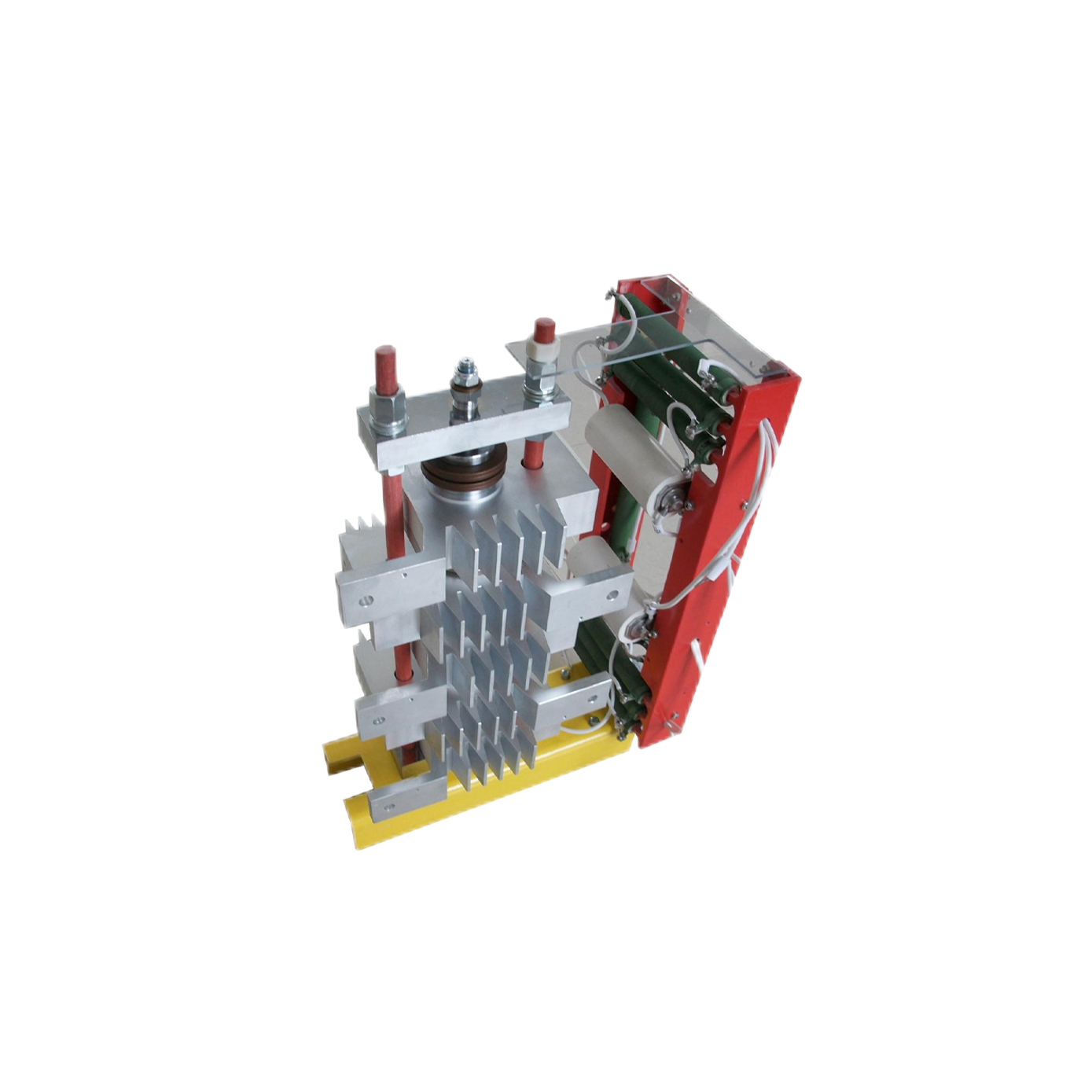

industrial chip for inverter

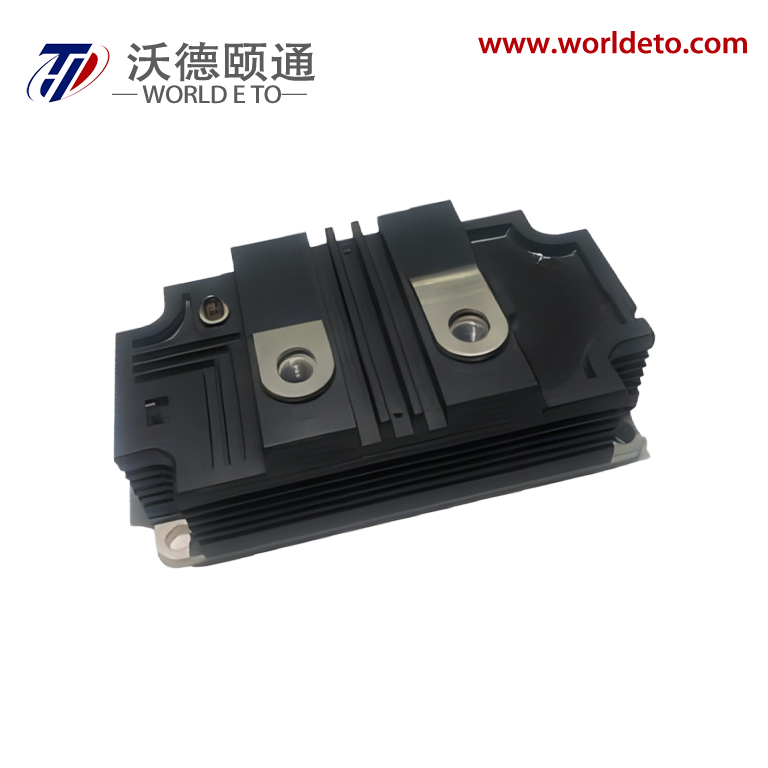

Industrial chip for inverter represents a critical semiconductor component that serves as the brain of power conversion systems in manufacturing environments. This specialized microprocessor controls the precise switching of power transistors within inverter circuits, enabling the efficient transformation of direct current (DC) to alternating current (AC) power. The industrial chip for inverter incorporates sophisticated algorithms and real-time processing capabilities to manage complex power conversion tasks across diverse industrial applications. Modern industrial chip for inverter designs feature advanced pulse-width modulation (PWM) control mechanisms that regulate voltage, frequency, and current output parameters with exceptional accuracy. These chips integrate multiple protection functions, including overcurrent detection, thermal monitoring, and fault diagnostic capabilities that ensure reliable operation in harsh industrial environments. The technological architecture of an industrial chip for inverter typically includes high-speed analog-to-digital converters, dedicated signal processing units, and communication interfaces that enable seamless integration with industrial automation systems. Key technological features encompass programmable control loops, adaptive switching algorithms, and energy optimization routines that maximize system efficiency while minimizing power losses. Applications span across motor drive systems, renewable energy installations, uninterruptible power supplies, welding equipment, and industrial heating systems. The industrial chip for inverter enables precise motor speed control in manufacturing processes, facilitating improved product quality and reduced energy consumption. In renewable energy applications, these chips optimize power extraction from solar panels and wind turbines, converting variable DC inputs into stable AC outputs suitable for grid connection. The robust design specifications of industrial chip for inverter solutions ensure operation across extended temperature ranges, resistance to electromagnetic interference, and compliance with stringent industrial safety standards, making them indispensable components in modern industrial power management systems.