How IGBT Modules Enhance Welding Efficiency

High-Speed Switching for Precision Arc Control

IGBT modules are really important in modern welding because they allow for fast switching speeds that help control the welding arc with much greater precision. When these modules switch rapidly, it keeps the welding arc stable which means better quality welds overall. Traditional methods tend to create all sorts of defects, but with IGBT technology, those problems get reduced quite a bit while at the same time making the whole process faster. Better control over the arc leads to smoother finishes on welds too, cutting down on issues like blowholes and cracks that ruin the integrity of the work. Industry data shows welding operations using IGBT modules can actually go about 30% quicker than what was possible with older tech from just a few years back. For manufacturers running against clock constraints, this kind of boost makes a big difference in getting products out the door on schedule without sacrificing quality standards.

Reducing Energy Loss in Inverter-Based Systems

IGBT modules make a big difference for energy efficiency in welding systems that use inverters because they cut down on energy losses when converting power. The modules actually help save around 20% on overall energy use, something that factory owners notice in their bottom line while also helping reduce carbon footprints. For welders working today, better performing IGBT modules mean lower running costs simply because less electricity gets used. Looking at what's happening across the industry, companies report real money savings from switching to these modules, especially when it comes to monthly electric bills. The savings aren't just numbers on a spreadsheet either they give manufacturers breathing room to upgrade equipment or boost profits without having to raise prices.

Optimizing Power Density in Compact Welding Equipment

IGBT modules allow manufacturers to pack more power into smaller packages, which means they can build welding equipment that takes up less space and weighs less too. For construction sites and repair shops needing mobile welding solutions without sacrificing quality, these improvements matter a lot. The space saving aspect really counts when working in tight spots or loading/unloading gear between jobs. Take Infineon's IGBT products as a case in point – companies report better portability without any drop off in weld strength or consistency. As factories continue shrinking their footprints while expanding output requirements, the ability to miniaturize welding systems through IGBT tech shows just how flexible modern manufacturing has become in responding to changing conditions on shop floors across different sectors.

Key Technical Advantages of IGBT Modules in Welding

Superior Voltage Handling for Industrial Applications

When it comes to welding in industrial settings, how well equipment handles voltage matters a lot. That's where IGBT modules really shine. These components work great at managing high voltages better than most alternatives on the market today. Their strength becomes apparent during tough situations that demand consistent performance from electrical systems. A recent analysis from power electronics specialists shows IGBTs can manage higher voltage levels compared to older tech like MOSFETs and BJTs, which means they keep performing even when things get stressful. Many engineers who've worked with these modules point to successful projects where proper voltage control was critical. The fact that IGBTs can tackle tougher voltage requirements has made them go-to components for factories looking to upgrade their welding operations without compromising safety or efficiency.

Low Conduction Losses in Continuous Operation

All electrical systems experience what we call conduction losses, but using IGBT modules cuts these down quite a bit, something really important for keeping welding systems running smoothly over time. Basically, these losses happen because electricity meets resistance as it moves through semiconductor materials. The good news is that IGBT modules cut down on this problem much better than older semiconductor tech, so energy gets used more efficiently. Manufacturers who switched to IGBTs report seeing real improvements in their bottom line. Take automotive manufacturing plants for instance many have seen significant drops in energy costs while maintaining output levels. Beyond just saving money, these modules actually improve how well welds hold together, making them essential equipment for factories where producing large volumes consistently matters most.

Compatibility with PWM Control Strategies

IGBT modules work really well with PWM control methods, giving them a big edge in today's welding tech. The way PWM controls things makes all the difference when it comes to getting precise results during welding operations. Without good control over these parameters, weld quality drops off fast. When IGBTs integrate smoothly with PWM systems, welders can adjust their setup exactly how they need for different jobs, which means better welds across the board. Industry professionals often point out that being able to tweak those welding settings through PWM is what separates average from excellent outcomes. We see this benefit across many sectors including cars, power generation equipment, and even gadgets we use daily. The fact that IGBTs play so nicely with PWM just goes to show why they're becoming standard issue in shops looking to maintain top notch weld quality.

Thermal Management Solutions for IGBT-Driven Welders

Advanced Cooling Techniques for High-Temperature Operations

Keeping things cool during welding operations matters a lot when it comes to how well equipment performs over time, especially for those Insulated Gate Bipolar Transistor or IGBT modules they use. Good cooling methods matter because these operations generate so much heat. Think about liquid cooling systems paired with proper heat sinks - these setups really help get rid of all that excess warmth before it becomes a problem. The difference makes itself known pretty quickly too; shops that implement proper thermal management often see their failure rates drop by around 30%. When welders invest in quality cooling options, their machines tend to run better without constant breakdowns. Equipment lasts longer this way, and nobody wants to spend extra money on replacements when there's already enough going on with day-to-day maintenance issues. Proper temperature control just makes sense for anyone serious about getting reliable results from their welding setup.

Thermal Resistance Optimization in Module Design

When it comes to IGBT module design, thermal resistance remains a top priority because it directly affects how long these modules last in welding applications. Getting heat away from those delicate electronics makes all the difference in system performance. When done right, the modules stay cooler, so they don't overheat and fail unexpectedly. The industry has seen some interesting improvements lately. Manufacturers are experimenting with different material layers and coming up with smarter cooling designs. These changes do more than just make the modules work better. They actually prolong their lifespan too. Less downtime means fewer replacement costs, something that matters a lot in welding shops where production needs to keep running nonstop.

Preventing Overheating in Demanding Welding Cycles

When running those intense welding cycles, keeping IGBT modules from overheating requires some pretty smart techniques. Most setups now include thermal sensors paired with feedback systems that monitor what's happening inside the module. These monitoring systems help keep things running at just the right temperature by constantly checking heat levels and making necessary adjustments before problems occur. Industry professionals have seen firsthand how this kind of proactive cooling can cut down on downtime and save money on repairs over time. Putting in place good overheating protection means welders don't get stuck waiting for equipment failures during critical jobs. The result? Better performance across the board when working under pressure conditions where every minute counts.

Future Innovations in IGBT Welding Technology

Silicon Carbide (SiC) Hybrid Modules for Enhanced Efficiency

Silicon Carbide or SiC hybrid modules might just revolutionize how we do welding work across various industries because they perform much better than traditional silicon IGBT modules when it comes to efficiency and handling heat. What makes them stand out is that they pack more power into smaller spaces while standing up to higher temperatures without breaking down, which means equipment lasts longer between repairs and saves money on maintenance over time. Many welding shops have started switching to SiC tech lately, mainly because customers want systems that last longer and don't waste so much energy. Market analysts predict big growth ahead for these modules worldwide as companies upgrade their welding setups. With all these improvements happening right now, it's clear why manufacturers see SiC as something fundamental for what comes next in welding technology development.

Smart Monitoring Systems for Predictive Maintenance

Smart monitoring systems integrated into IGBT driven welders represent one of the most important developments happening right now in welding tech. These systems keep track of how well the equipment is performing all the time, so maintenance crews can fix problems before they actually break down. When it comes to predictive maintenance, research shows machines last longer when monitored this way. Some reports even mention around 20% less downtime across different manufacturing settings, which obviously saves money in the long run. For shops running welding operations day after day, having these advanced monitoring tools means fewer production stoppages and smoother workflow overall. That's why more companies are starting to see value in investing in smart monitoring solutions for their welding equipment.

Eco-Friendly Manufacturing of Next-Gen Welding Modules

We're seeing some real changes happening in the welding business right now as companies start moving towards greener manufacturing methods. More and more firms are working hard to cut down on waste while finding ways to include environmentally friendly materials throughout their welding module production lines. What's interesting is how this isn't just about new technology anymore it's also showing genuine concern for our planet's future. Industry data actually shows most people involved in the sector support these green efforts, which helps build better reputations and keeps customers coming back. Looking ahead, upcoming welding modules seem destined to carry forward these sustainability trends, trying to find that sweet spot where cutting edge tech meets responsible environmental practices without compromising quality or performance.

FAQ Section

What are IGBT modules?

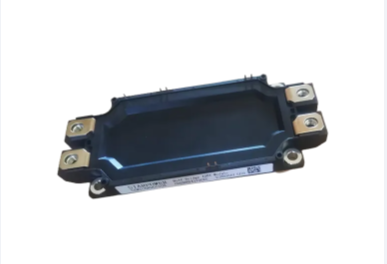

IGBT modules, or Insulated Gate Bipolar Transistor modules, are semiconductor devices used to enhance welding efficiency by providing high-speed switching, reducing energy loss, and optimizing power density.

How do IGBT modules improve welding efficiency?

They offer high-speed switching for precision arc control, which enhances weld quality. They also reduce energy consumption in inverter-based systems and allow for compact welding equipment design.

What are the advantages of IGBT modules in welding?

Advantages include superior voltage handling, low conduction losses, and compatibility with PWM control strategies, all of which enhance performance and reliability.

What role do IGBT modules play in thermal management?

IGBT modules benefit from advanced cooling techniques and optimized thermal resistance design, preventing overheating and extending equipment lifespan during high-temperature welding operations.

Are there any future innovations related to IGBT welding technology?

Yes, future innovations include the usage of Silicon Carbide (SiC) hybrid modules for enhanced efficiency and the integration of smart monitoring systems for predictive maintenance.