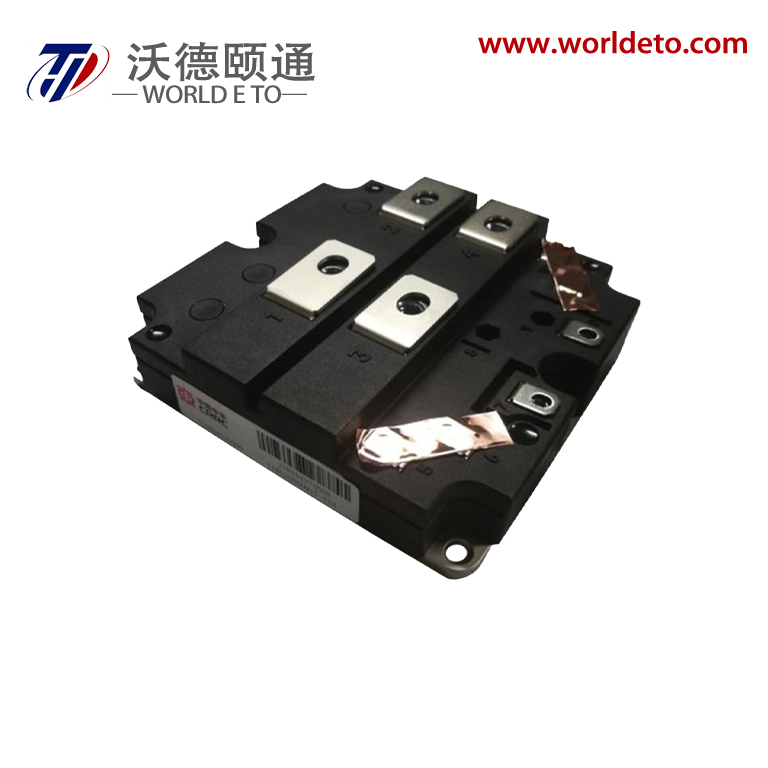

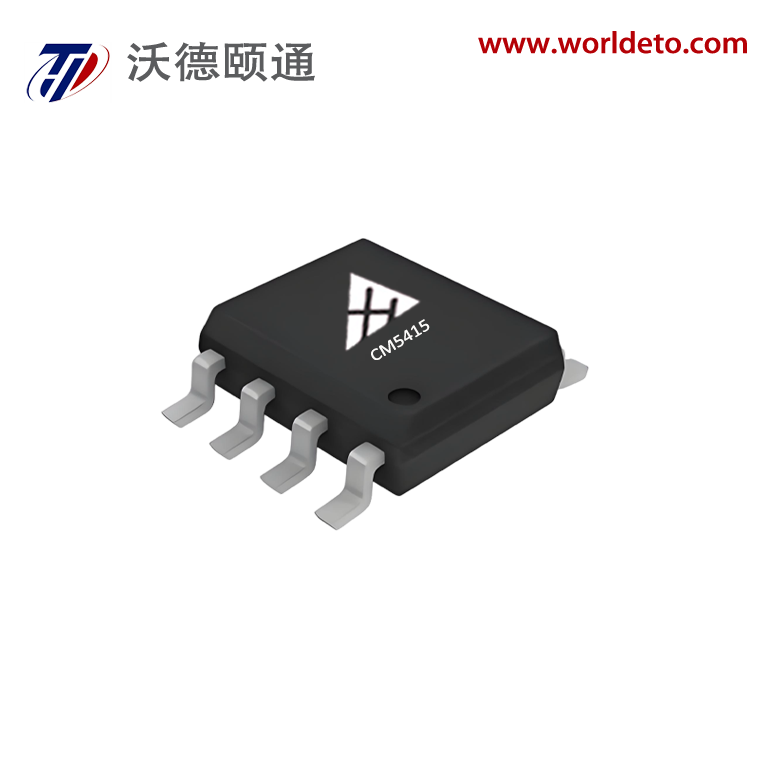

diode wafer

A diode wafer represents a fundamental semiconductor component that serves as the foundation for manufacturing electronic diodes used across countless applications in modern technology. This thin, circular disc of semiconductor material, typically made from silicon or gallium arsenide, undergoes precise fabrication processes to create the essential p-n junction that defines diode functionality. The diode wafer manufacturing process involves carefully controlled doping procedures where impurities are introduced into the pure semiconductor substrate to create regions with different electrical properties. The primary function of a diode wafer is to allow electrical current to flow in only one direction while blocking reverse current flow. This unidirectional conductivity makes diode wafers essential components in rectification circuits, voltage regulation systems, and signal processing applications. The technological features of diode wafers include their crystalline structure, which provides excellent electrical properties and thermal stability. Modern diode wafer production utilizes advanced lithography techniques and ion implantation methods to achieve precise doping profiles and junction characteristics. The wafer surface undergoes multiple processing steps including cleaning, oxidation, photolithography, etching, and metallization to create the final device structure. Quality control measures ensure consistent electrical parameters across the entire wafer surface. Applications for diode wafers span numerous industries including consumer electronics, automotive systems, telecommunications equipment, power conversion devices, and renewable energy systems. In power electronics, diode wafers enable efficient AC-to-DC conversion in power supplies and battery chargers. The telecommunications industry relies on diode wafers for signal processing and frequency mixing applications. Solar panel systems utilize diode wafers to prevent reverse current flow and optimize energy harvesting efficiency. The automotive sector incorporates diode wafers in alternators, LED lighting systems, and electronic control units.