Enhanced Reliability and Longevity in Demanding Environments

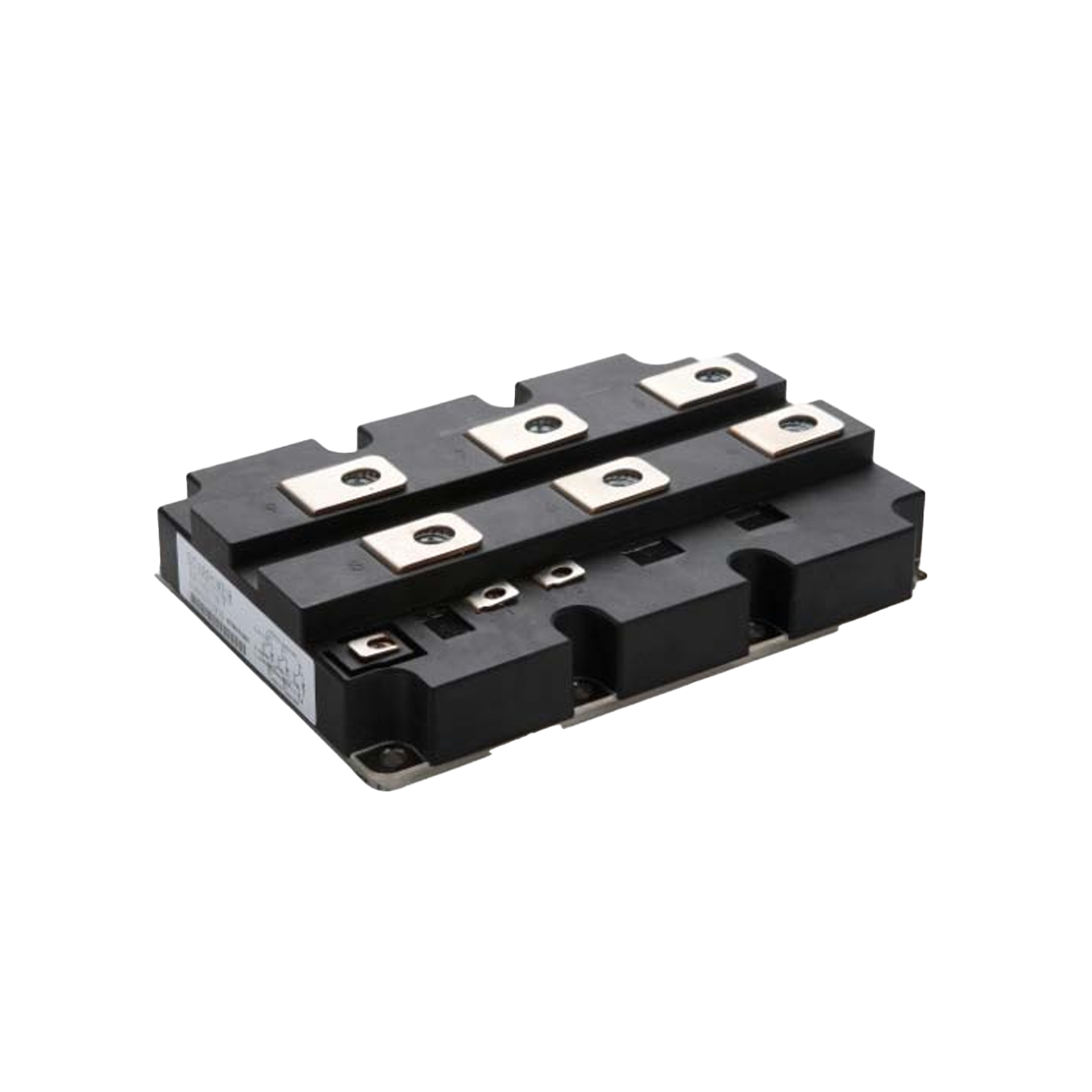

The three phase thyristor stands out for its exceptional reliability and longevity, characteristics that make it the preferred choice for mission-critical industrial applications. The solid-state construction of three phase thyristors eliminates mechanical moving parts that typically wear out over time, resulting in significantly longer operational lifespans compared to traditional electromechanical switching devices. This robust design enables continuous operation for years without requiring major maintenance, dramatically reducing downtime and associated costs. The thermal management capabilities of modern three phase thyristor systems ensure stable operation even under extreme temperature conditions, incorporating advanced heat dissipation technologies that prevent overheating and thermal stress. These devices undergo rigorous testing procedures that simulate decades of operation under various stress conditions, validating their ability to perform reliably in real-world applications. The protective features built into three phase thyristor systems provide comprehensive safeguards against common electrical problems, including overcurrent conditions, voltage spikes, and ground faults. These protection mechanisms not only preserve the thyristor itself but also protect connected equipment from damage, providing system-wide reliability improvements. The predictable failure modes of three phase thyristors enable proactive maintenance strategies, where operators can monitor device performance indicators and schedule replacements before failures occur. This predictability contrasts sharply with mechanical switches that often fail suddenly without warning, causing unexpected production interruptions. The quality manufacturing standards applied to three phase thyristor production ensure consistent performance across all units, eliminating the variability that can plague other switching technologies. Environmental resistance represents another key reliability factor, with three phase thyristors designed to withstand moisture, dust, chemicals, and vibrations commonly found in industrial settings. The modular architecture of these systems allows for redundant configurations where backup thyristors can automatically engage if primary units experience problems, ensuring uninterrupted operation for critical processes. Long-term reliability translates into significant economic benefits, including reduced spare parts inventory, lower maintenance labor costs, and improved production scheduling reliability that enhances customer satisfaction and business reputation.