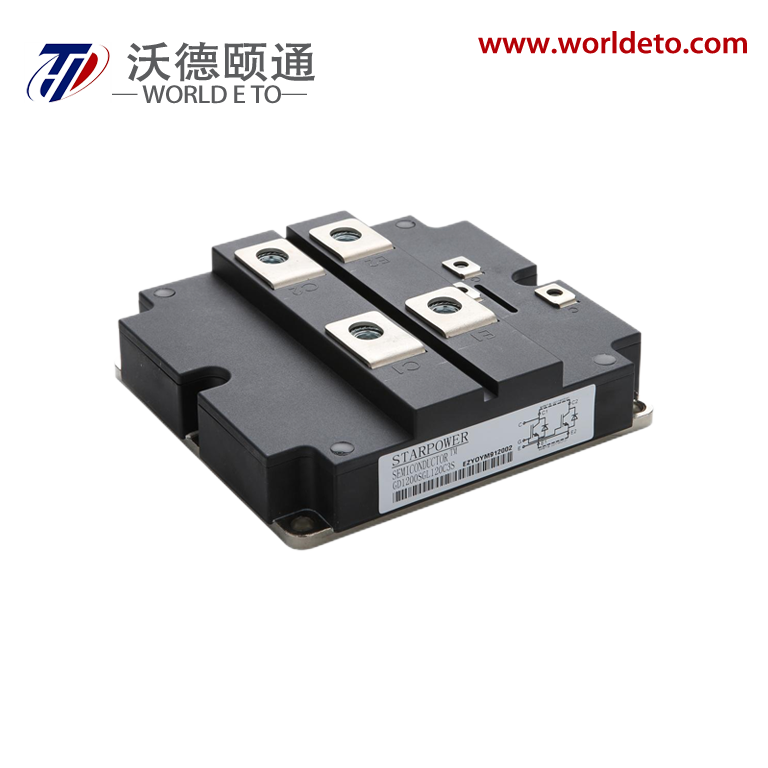

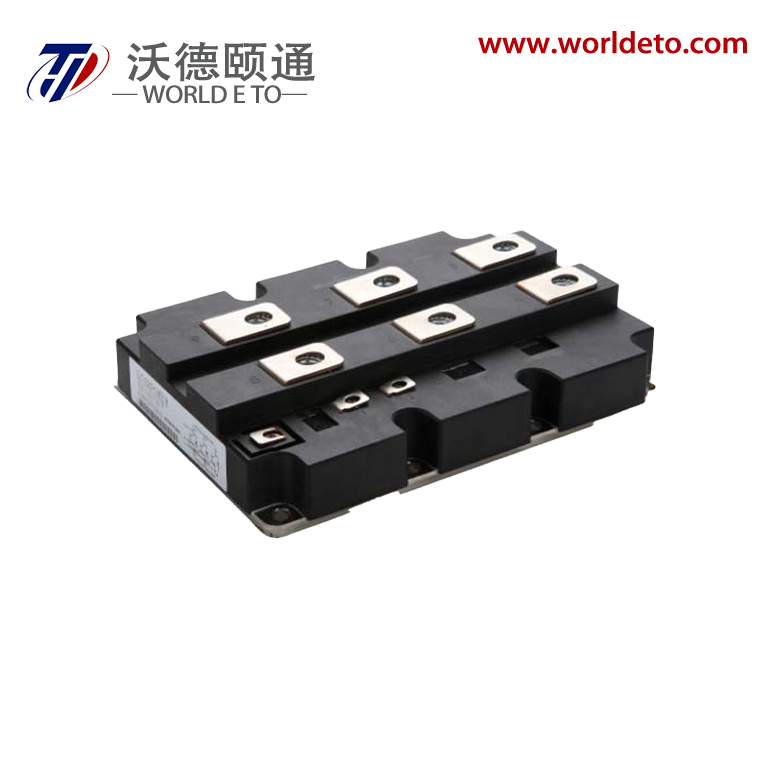

igbt manufacturer

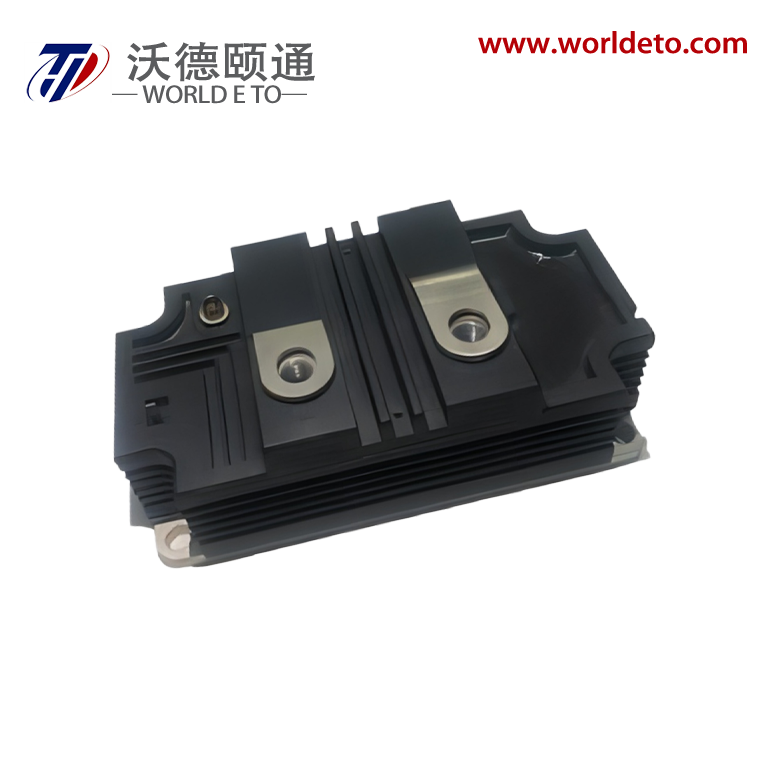

An igbt manufacturer represents a specialized company focused on developing, producing, and distributing Insulated Gate Bipolar Transistors, which serve as critical semiconductor components in modern power electronics systems. These manufacturers combine advanced engineering expertise with cutting-edge fabrication technologies to create high-performance switching devices that bridge the gap between traditional MOSFETs and bipolar junction transistors. The primary function of an igbt manufacturer involves designing semiconductor solutions that can handle high voltage and current applications while maintaining efficient switching capabilities. Their technological features include sophisticated gate drive circuits, optimized chip architectures, and enhanced thermal management systems that ensure reliable operation across diverse environmental conditions. These manufacturers typically employ state-of-the-art clean room facilities, precision wafer processing equipment, and rigorous quality control protocols to maintain consistent product standards. The core applications for products from an igbt manufacturer span multiple industries, including renewable energy systems, electric vehicle powertrains, industrial motor drives, uninterruptible power supplies, and smart grid infrastructure. In renewable energy applications, these components enable efficient power conversion in solar inverters and wind turbine systems. Electric vehicles rely heavily on IGBTs for motor control, battery management, and charging systems. Industrial automation benefits from these devices through variable frequency drives, servo motors, and robotic control systems. The igbt manufacturer also serves the consumer electronics market with products for home appliances, air conditioning systems, and power tools. Advanced manufacturing processes employed by leading manufacturers include ion implantation, metallization, passivation, and packaging techniques that enhance device performance and longevity. Quality assurance protocols ensure each product meets stringent reliability standards through extensive testing procedures, including thermal cycling, humidity exposure, and electrical stress testing. The igbt manufacturer continuously invests in research and development to improve switching speeds, reduce power losses, and enhance overall system efficiency.