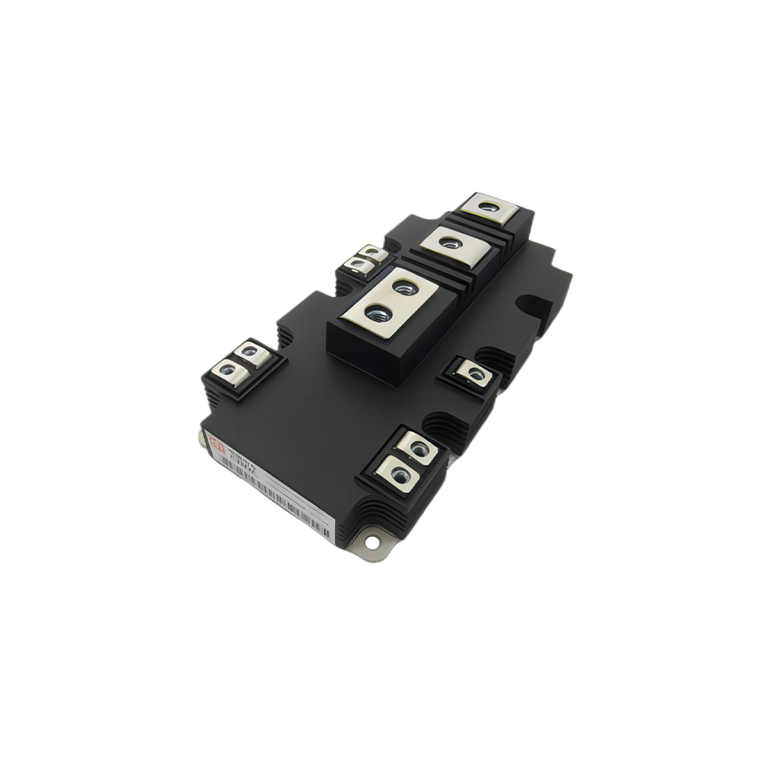

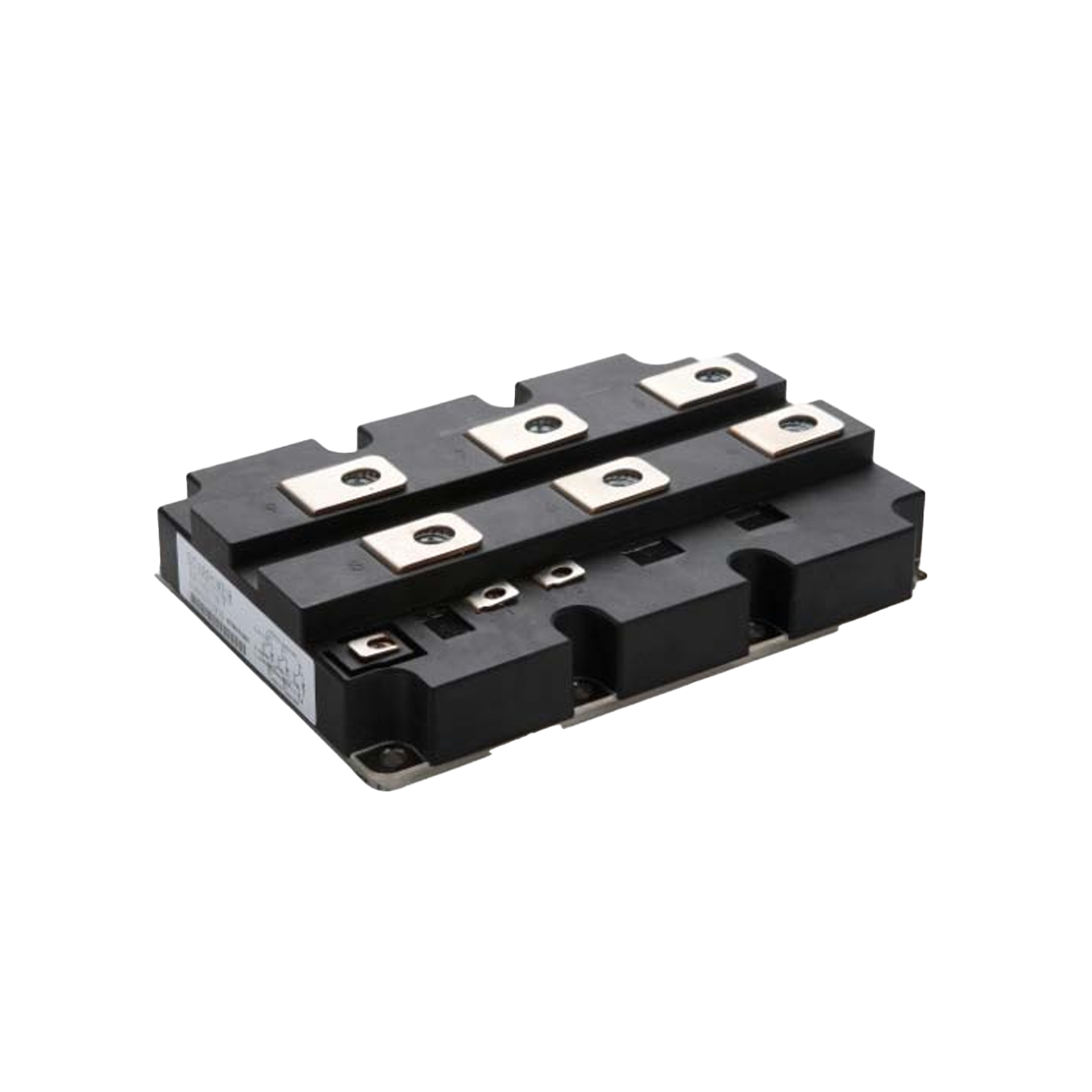

thyristor manufacturer

A thyristor manufacturer specializes in producing semiconductor devices that function as electronically controlled switches, serving critical roles in power electronics and control systems across diverse industries. These specialized companies design and fabricate thyristors, which are four-layer semiconductor devices capable of controlling high voltage and current applications with remarkable precision. The primary function of thyristors involves switching electrical circuits on and off, regulating power flow, and converting alternating current to direct current in various electronic systems. Modern thyristor manufacturer facilities employ advanced silicon processing technologies, utilizing sophisticated clean room environments and precision manufacturing equipment to ensure consistent product quality. The technological features of contemporary thyristor production include ion implantation processes, diffusion techniques, and advanced packaging methods that enhance device reliability and performance characteristics. These manufacturers typically produce various thyristor types including Silicon Controlled Rectifiers (SCR), Gate Turn-Off thyristors (GTO), and Integrated Gate Commutated Thyristors (IGCT), each designed for specific application requirements. Quality control systems within thyristor manufacturer operations encompass comprehensive testing protocols that verify electrical parameters, thermal characteristics, and long-term reliability standards. Applications for thyristor products span numerous sectors including industrial motor drives, power transmission systems, railway traction equipment, renewable energy installations, and consumer electronics. The manufacturing process involves multiple stages from wafer preparation through final assembly, with each thyristor manufacturer implementing proprietary techniques to optimize device performance. Research and development activities within these companies focus on improving switching speeds, reducing power losses, and enhancing thermal management capabilities. Supply chain management represents another crucial aspect of thyristor manufacturer operations, ensuring consistent raw material availability and maintaining production schedules to meet customer demands across global markets.