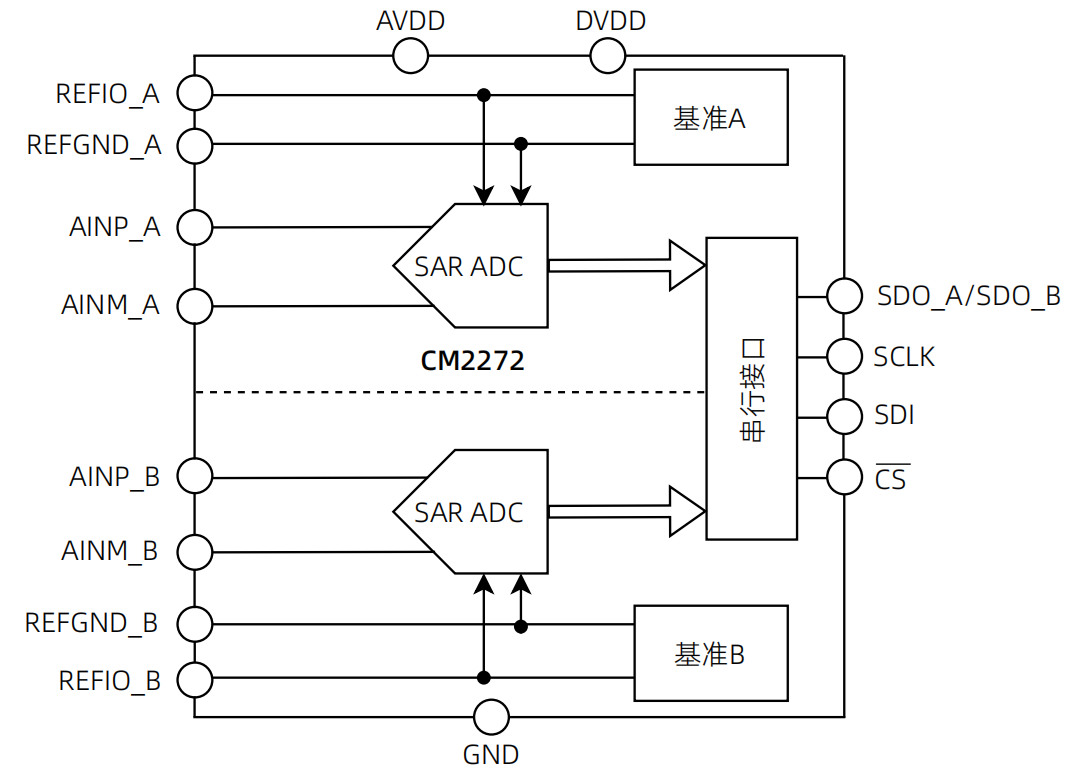

The CM2272 is a 16-bit, high-speed, dual-channel synchronous sampling SAR ADC that supports fully differential analog inputs.

The CM2272 supports a wide range of analog power supply voltages, with each channel featuring its own reference source. It is also equipped with a flexible serial interface that supports multiple data reading modes.

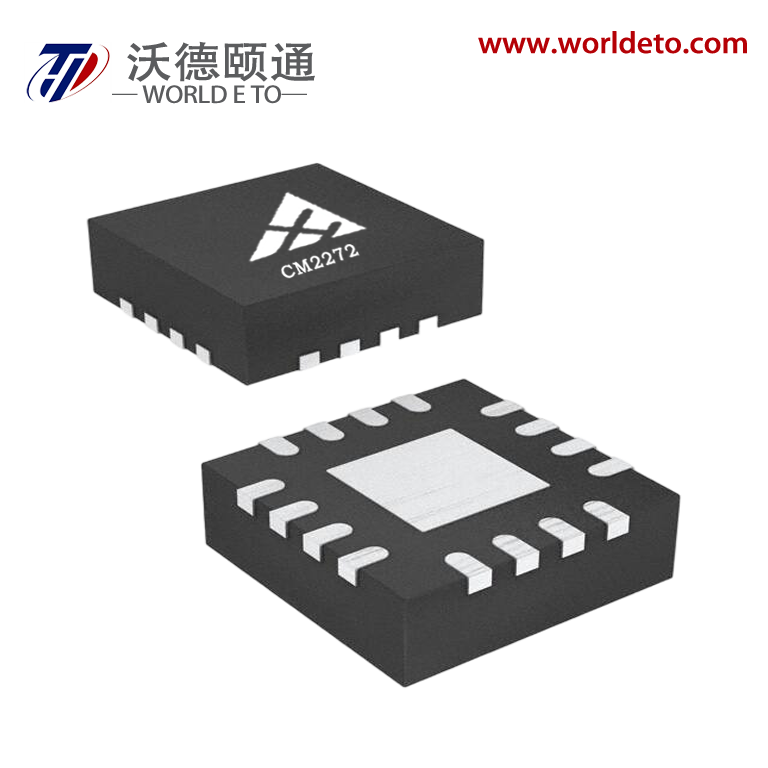

The CM2272 comes in a QFN16 package, with an operating temperature range of −40°C to 125°C.

Features

Dual-channel synchronous sampling

Fully differential input support

Sampling rate: 2 MSPS

INL: ±1 LSB

DNL: ±0.4 LSB

SNR: 90.4 dB typical

THD: −108 dB typical (±VREF input range)

Dual 2.5 V internal reference voltage

Channel isolation: −122 dB typical

VDD current: 20 mA typical

QFN16 3 mm × 3 mm package

Applications

Motor control: Position measurement using encoders

Optical networks: Erbium-doped fiber amplifier (EDFA) gain control loops

Protection relays

Power quality measurement

Three-phase power control

Programmable logic controllers

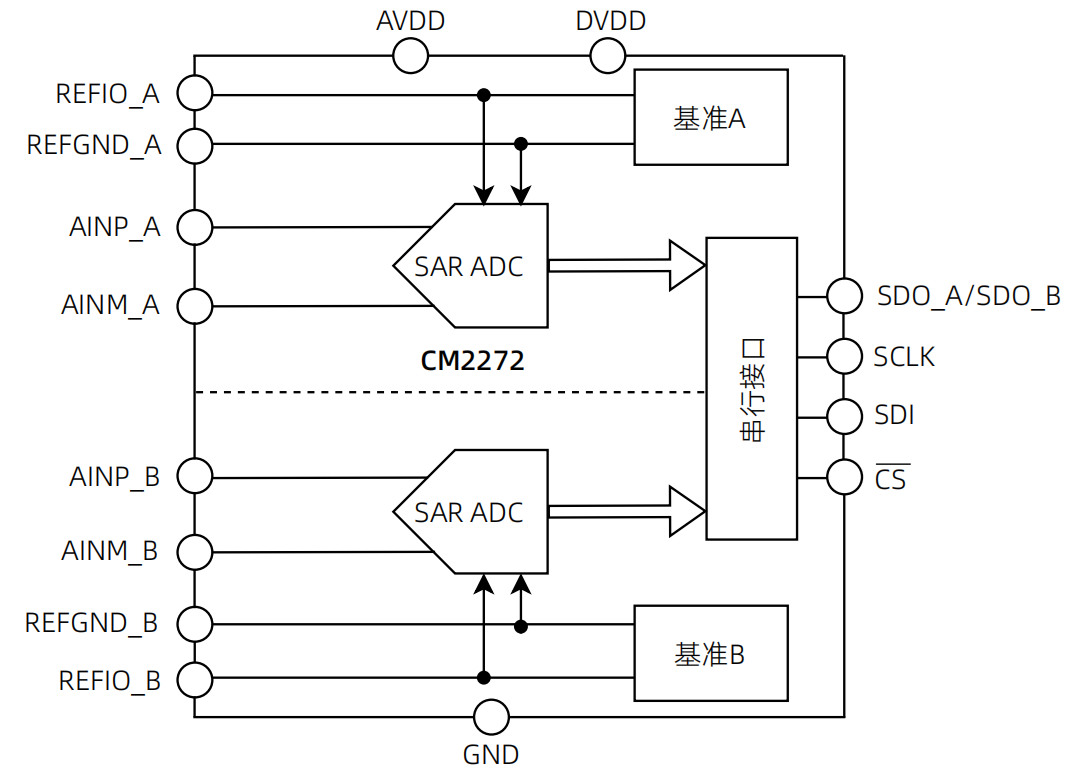

Architecture Block Diagram

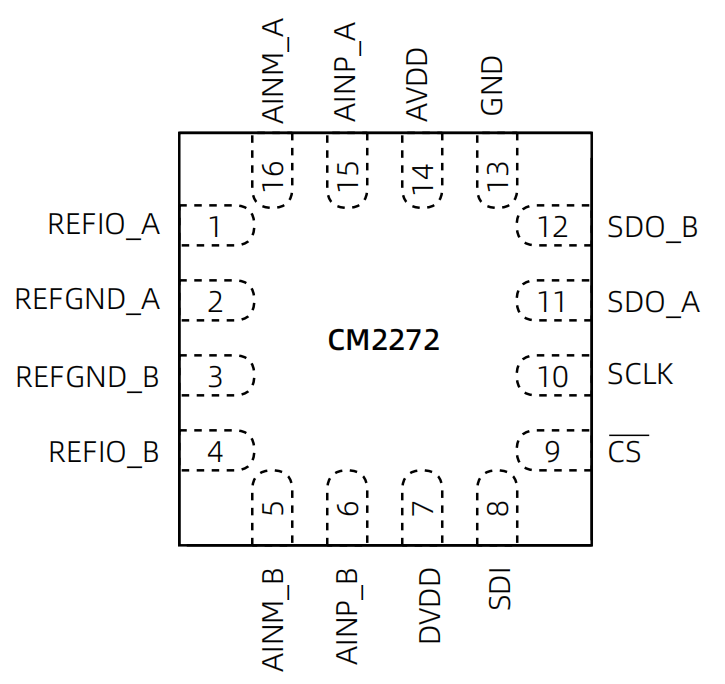

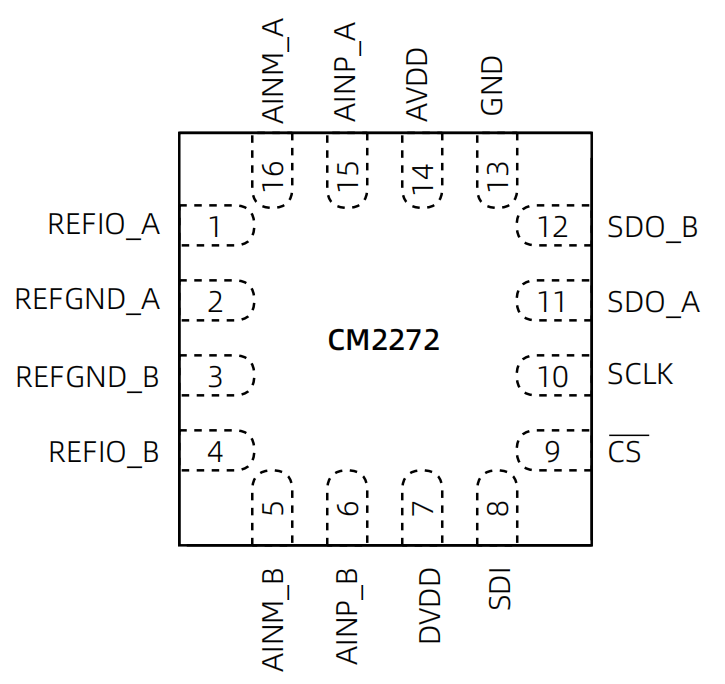

Pin configuration

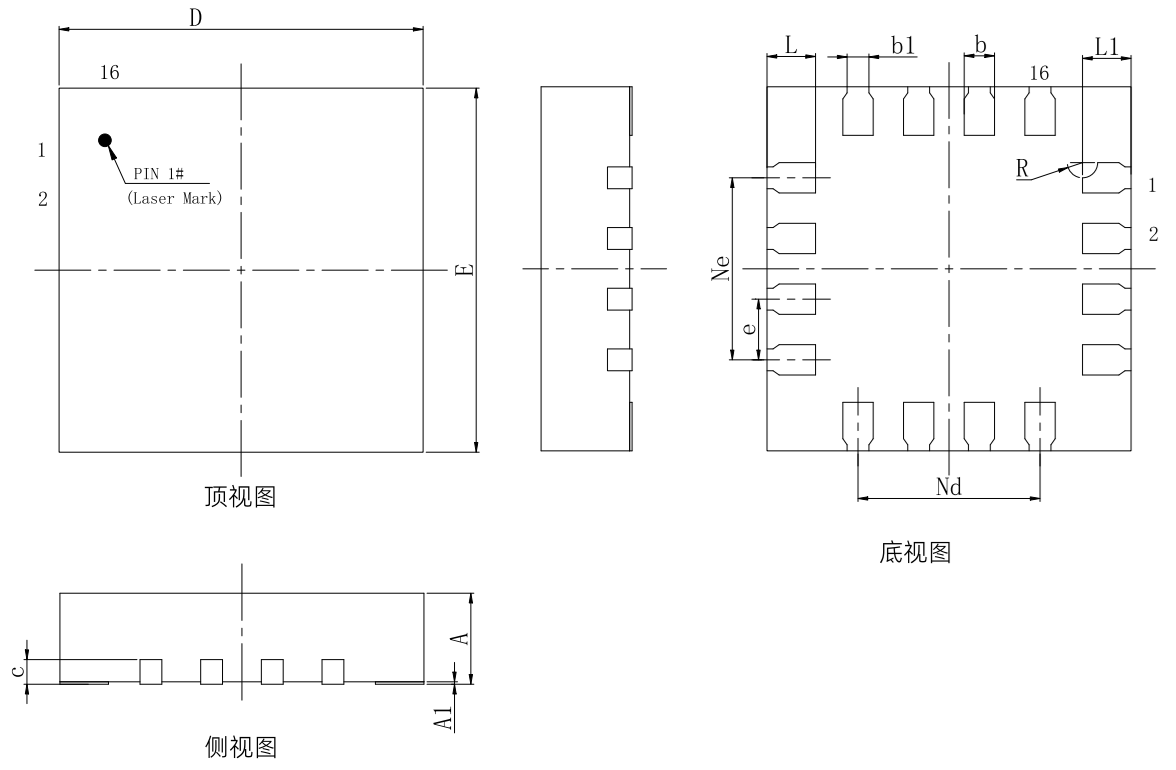

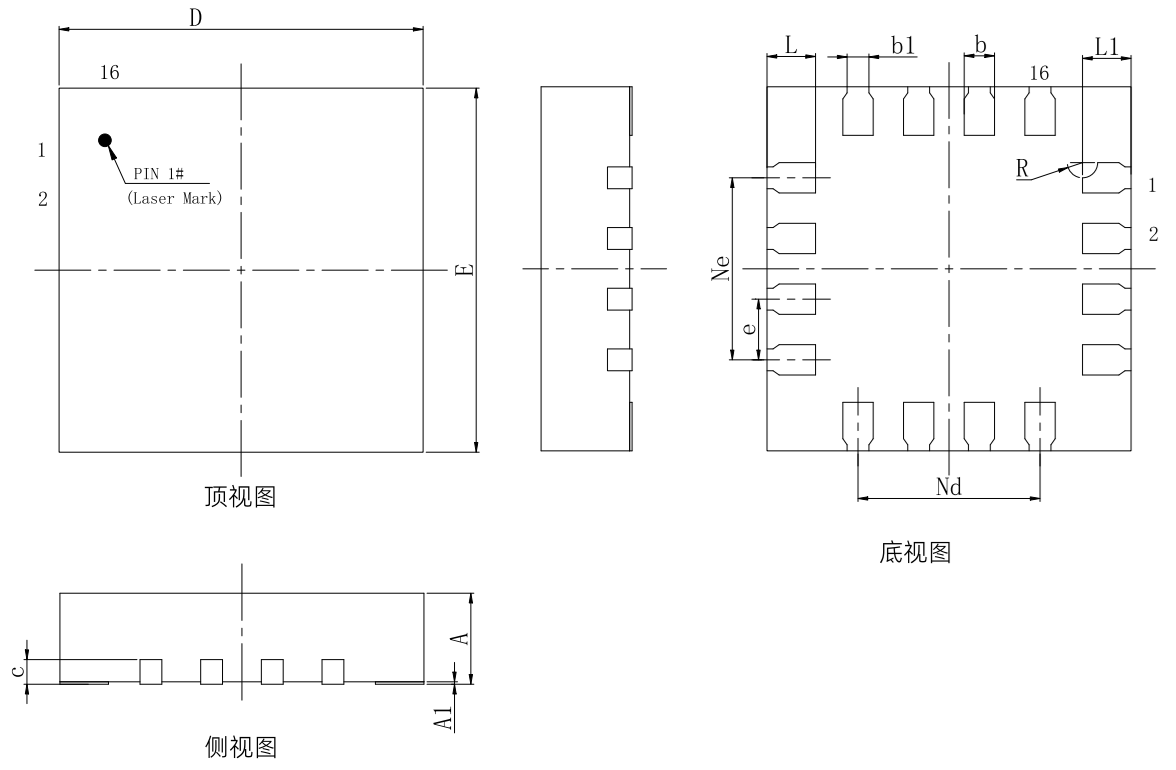

Appearance dimensions

| Mark |

Dimensions( mm) |

| Min |

Typical |

Max |

| A |

0.70 |

0.75 |

0.80 |

| A1 |

0 |

0.02 |

0.05 |

| b |

0.20 |

0.25 |

0.30 |

| b1 |

0.18 (REF) |

| c |

0.20 (REF) |

| D |

2.90 |

3.00 |

3.10 |

| e |

0.50 (BSC) |

| E |

2.90 |

3.00 |

3.10 |

| Nd |

1.50 (BSC) |

| Ne |

1.50 (BSC) |

| L |

0.35 |

0.40 |

0.45 |

| L1 |

0.30 |

0.40 |

0.50 |

| R |

0.13 (REF) |

Application Cases of CM2272 for Programmable Logic Controller (PLC)

Overview:

In a Programmable Logic Controller (PLC) system, precise measurement and control of analog signals are essential for various industrial automation processes. The CM2272, a 16-bit high-speed dual-channel synchronous sampling SAR ADC, is an ideal solution for such applications due to its ability to provide accurate and fast analog-to-digital conversion with fully differential input support. This case outlines how the CM2272 can be applied in a PLC for real-time monitoring and control in an industrial automation environment.

System Components:

CM2272 ADC: The core component for converting analog signals into digital signals for processing by the PLC.

PLC: A programmable controller used to automate various industrial processes such as temperature control, motor speed regulation, and pressure monitoring.

Sensors/Actuators: Various industrial sensors, such as temperature sensors, pressure sensors, or motor encoders, provide the analog signals to be measured.

Communication Interface: A communication interface such as SPI or a custom serial protocol is used to transfer data between the CM2272 and the PLC.

Power Supply: The system will operate within the voltage range supported by the CM2272 (e.g., 2.5V for the internal reference voltage, VDD range 3.3V to 5V).

PLC-Controlled Application Example: Motor Speed Control

In this example, the CM2272 is used in a motor speed control system, where the PLC is responsible for controlling the speed of a motor based on real-time data from a tachometer or encoder.

Key Steps in the Application:

-

Analog Signal Acquisition:

The tachometer or encoder generates an analog voltage signal proportional to the motor speed. This analog signal is fed into the fully differential inputs of the CM2272.

The CM2272 samples the signal at 2 MSPS with a 16-bit resolution and converts it into a digital signal for further processing by the PLC.

-

Data Transmission to PLC:

The digital data from the CM2272 is transmitted to the PLC via an SPI interface. The PLC is configured to read the data from the CM2272 at regular intervals.

The PLC processes the data to determine the motor speed and compares it against a pre-set target speed value.

-

Processing and Control:

The PLC uses the motor speed data to make decisions. If the motor speed deviates from the target value, the PLC sends control signals to adjust the motor speed, for example, by controlling the output of a variable frequency drive (VFD) or adjusting the power to the motor.

The control loop operates in real-time, with the PLC continuously monitoring the motor speed and adjusting the motor control parameters to maintain the desired speed.

-

Monitoring and Feedback:

The PLC can also monitor the performance of the entire system, including checking for anomalies in the motor speed and adjusting parameters such as acceleration, deceleration, and torque.

The CM2272’s high accuracy (SNR of 90.4 dB, THD of -108 dB) ensures that the motor speed data is reliable and can be used for precise control.

-

System Alerts:

If the motor speed exceeds safe limits or falls below the required threshold, the PLC can trigger alarms or shutdown procedures to protect the motor from damage.

The system can be configured to log data for later analysis, allowing maintenance teams to detect potential issues early and prevent unplanned downtime.

Key Benefits of Using CM2272 in PLC System:

High Precision and Speed: The CM2272’s 16-bit resolution and 2 MSPS sampling rate ensure that the motor speed is measured accurately and quickly, enabling precise control.

Fully Differential Inputs: The ability to support fully differential inputs ensures high signal integrity and noise immunity, which is especially important in industrial environments with high electrical noise.

Dual-Channel Synchronization: The dual-channel capability allows the simultaneous sampling of multiple signals, which is useful for applications where multiple sensors are used, such as monitoring motor speed and load simultaneously.

Low Power Consumption: The CM2272’s low power consumption (3.5mW at 1 MSPS) makes it suitable for embedded systems where energy efficiency is critical.

Wide Temperature Range: With an operating temperature range of -40°C to 125°C, the CM2272 can operate in harsh industrial environments.

Conclusion:

The CM2272 ADC can significantly enhance the performance of PLC-based systems, providing precise and high-speed analog-to-digital conversion in applications such as motor control. Its dual-channel, high-speed capabilities, along with the fully differential input and flexible serial interface, make it a valuable component in a wide range of industrial automation systems. The combination of accuracy, reliability, and low power consumption ensures that the system can operate efficiently in demanding conditions, leading to improved process control and system performance.

Product list

SAR ADC

| P/N |

Type |

Package |

MPQ(Pcs) |

Benchmarks against |

| CM2248-QFPTR |

ADC |

Tray |

1600 |

AD7606 |

| CM2249-QFPT |

ADC |

Tray |

900 |

AD7616 |

| CM2368-QFPTR |

ADC |

Tray |

1600 |

AD7606C-18 |

| CM2268-QFPTR |

ADC |

Tray |

1600 |

AD7606C-16 |

| CM2219-QFNTR |

ADC |

Tray |

4900 |

AD7699 |

| CM2209-QFNTR |

ADC |

Tray |

4900 |

AD7689 |

| CM2322-MSOTA |

ADC |

Tray |

4000 |

AD7982 |

| CM2220-MSOTA |

ADC |

Reel |

4000 |

AD7980 |

| CM2431-MSOTA |

ADC |

Tray |

4000 |

AD4020 |

| CM2272-MSOTA |

ADC |

Reel |

5000 |

ADS8354 |

About Us

We focus on the application of IGBT products. Based on the application of IGBT, we have expanded our product spectrum tohigh-end Power Assemblies customization, at the same time ,Our business has expanded into the field of automation control products, including ADC/DAC, LDO, instrumentation amplifiers, electromagnetic relays, PhotoMOS, and MOSFET. In this way, we can cooperate with top Chinese manufacturers in our areas of expertise to provide reliable and cost-effective products to our customers.

Founded on the principles of innovation and excellence,stand at the forefront of semiconductor semiconductor alternative solutions and technology.

Our vision is that provide alternative solutions to our customers, improve the cost performance of their application solutions and ensure the security of their supply chain by made in China.

Our users