Introduction : Le rôle pivot des modules IGBT dans la technologie EV

Les modules IGBT jouent un rôle essentiel dans les véhicules électriques modernes, permettant de meilleures performances et une plus grande durabilité. Face à l'aggravation du changement climatique à travers le monde, les véhicules électriques sont considérés comme une solution pour un transport plus écologique. La volonté d'adopter des technologies plus propres a renforcé l'idée qu'il est indispensable d'améliorer tous les composants des VE, un objectif rendu possible grâce aux capacités intelligentes de contrôle des modules IGBT. Ces petits interrupteurs de puissance ont un impact significatif sur l'efficacité avec laquelle les véhicules électriques convertissent l'énergie électrique et gèrent la puissance dans l'ensemble du véhicule, ce qui constitue en fait un facteur clé de l'évolution rapide des véhicules électriques sur le plan technologique. Lorsque les modules IGBT s'améliorent dans le contrôle des moteurs et la gestion des batteries, ils permettent d'économiser de l'énergie tout en offrant aux conducteurs une conduite plus fluide. Nous assistons ainsi à des améliorations concrètes en matière de performances des véhicules électriques, jour après jour.

Fonctions principales des modules IGBT dans les véhicules électriques

Conversion de puissance : Pont entre les batteries DC et les moteurs AC

Les modules IGBT sont des composants vraiment importants dans les voitures électriques, car ils prennent l'électricité continue stockée dans la batterie et la transforment en courant alternatif qui alimente effectivement le moteur électrique. Sans cette conversion correctement effectuée, le moteur ne fonctionnerait tout simplement pas correctement. De nos jours, les modules IGBT modernes assurent des performances assez bonnes en matière de conversion d'énergie, atteignant parfois des taux d'efficacité proches de 95 % selon divers tests. Lorsque ces modules fonctionnent à de tels niveaux élevés, ils contribuent à s'assurer qu'une grande partie de l'énergie soit utilisée là où elle est nécessaire, plutôt que d'être perdue pendant le processus de conversion. Cela signifie une meilleure autonomie pour les propriétaires de véhicules électriques et des performances généralement améliorées pour l'ensemble des véhicules électriques.

Contrôle moteur : Précision et efficacité dans les systèmes de traction

Les modules IGBT font bien plus que simplement gérer la conversion d'énergie dans les véhicules électriques. Ils rendent également les systèmes de contrôle des moteurs beaucoup plus précis. Et lorsque les moteurs sont contrôlés avec précision, les voitures accélèrent et ralentissent de manière beaucoup plus fluide, offrant ainsi un meilleur confort de conduite global. Ce qui est intéressant, c'est l'impact sur le contrôle de la traction : grâce à une gestion aussi précise des moteurs, la puissance est correctement répartie sur chaque roue. Cela se traduit concrètement par une amélioration notable de la tenue de route dans diverses conditions. Les conducteurs se sentent plus en sécurité et plus confiants au volant, qu'ils soient bloqués dans les embouteillages en ville ou qu'ils traversent des routes de montagne difficiles.

Intégration de la gestion thermique dans les électroniques de puissance

La gestion de la chaleur reste l'une des fonctions essentielles que les modules IGBT gèrent particulièrement bien. Lorsque l'électronique de puissance à l'intérieur des véhicules électriques commence à générer une grande quantité de chaleur, il devient absolument indispensable de maintenir une température modérée si l'on souhaite que ces systèmes aient une longue durée de vie. Les récents progrès dans la gestion de cette chaleur ont également apporté une grande différence. Nous observons une meilleure performance globale, tout en réduisant considérablement les risques de surchauffe entraînant la fusion des composants. Certaines solutions particulièrement ingénieuses existent désormais pour dissiper efficacement la chaleur. Prenons par exemple les plaques de base à ondes refroidies directement. Ces composants jouent un rôle majeur dans l'amélioration des capacités de gestion thermique des modules IGBT, leur permettant de continuer à fonctionner correctement même lorsqu'ils sont sollicités intensément pendant les pics de charge.

Principaux Avantages des Modules IGBT pour les Véhicules Électriques

Amélioration de l'Efficacité Énergétique dans les Systèmes de Train Roulant

Les modules IGBT sont essentiels pour améliorer l'efficacité énergétique des groupes motopropulseurs des véhicules électriques. En réduisant la puissance perdue pendant le fonctionnement, ces composants semi-conducteurs rendent les VE moins coûteux à l'usage et plus respectueux de l'environnement. Selon des recherches récentes menées par des entreprises d'ingénierie automobile, lorsqu'elle est correctement intégrée dans les conceptions de véhicules, la technologie IGBT peut économiser entre 10 et 15 % d'énergie grâce à une répartition plus intelligente de la puissance dans différentes conditions de conduite. Quel est l'impact concret ? Des batteries plus durables qui n'ont pas besoin d'être rechargées aussi souvent, ce qui rend les voitures électriques bien plus pratiques pour les automobilistes du quotidien souhaitant passer des véhicules traditionnels à essence sans compromettre l'autonomie ou le confort.

Pertes de commutation réduites pour une autonomie étendue

Les modules IGBT permettent de réduire considérablement les pertes de commutation, ce qui signifie que les véhicules électriques peuvent parcourir des distances plus longues avant de nécessiter une recharge. Ces petits composants puissants gèrent le flux d'électricité à travers le système, améliorant ainsi les performances globales de la voiture et optimisant l'autonomie à chaque cycle de charge. Certaines études montrent que les technologies IGBT plus récentes pourraient augmenter l'autonomie d'environ 10 pour cent, offrant ainsi aux conducteurs une plus grande sérénité lors de trajets longue distance, sans se soucier de trouver une borne de recharge tous les quelques kilomètres. Moins d'énergie gaspillée se traduit également par une utilisation plus intelligente de la batterie, permettant au véhicule de fonctionner de manière plus fluide sans consommer inutilement ses ressources en cours d'utilisation.

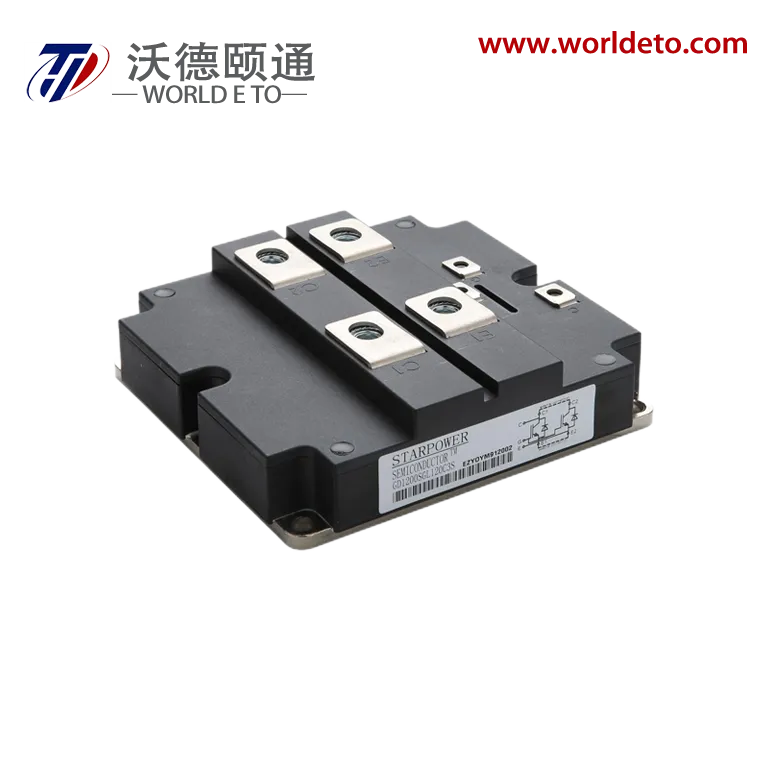

Conception compacte pour une haute densité de puissance

Les modules IGBT présentent des conceptions compactes qui augmentent la densité de puissance, un facteur particulièrement important lors de la construction de véhicules électriques. La réduction de l'encombrement permet aux ingénieurs d'intégrer davantage d'équipements dans les espaces réduits des batteries, où chaque centimètre compte. De grands constructeurs automobiles tels que Tesla et BMW ont démontré que ces modules permettent effectivement de gagner de la place à l'intérieur du véhicule, tout en installant correctement tous les composants nécessaires. Cette économie d'espace aide les fabricants à continuer de produire des véhicules esthétiques à l'extérieur tout en offrant des performances solides sous le capot. De plus, cela contribue à trouver cet équilibre difficile entre le poids du véhicule et sa puissance globale, une caractéristique très recherchée par les conducteurs actuels.

Impact des modules IGBT sur les performances des VE

Améliorations de l'accélération grâce à un commutateur plus rapide

Lorsque les modules IGBT commutent plus rapidement, ils améliorent considérablement la capacité des voitures électriques à accélérer, ce qui fait une grande différence en termes de performance globale. Ces modules permettent au véhicule de contrôler l'énergie bien plus rapidement, réduisant ainsi de manière notable le temps nécessaire pour passer de zéro à soixante miles par heure. Regardez ce qui se passe sur les pistes d'essai actuelles : les véhicules équipés des dernières technologies IGBT surpassent régulièrement les anciens modèles en matière d'accélération. Un bon exemple est donné par les dernières pièces de la gamme EDT2 d'Infineon. Elles fonctionnent si bien que les conducteurs ressentent réellement la différence en termes de réactivité. Qu'est-ce qui les rend spéciales ? Eh bien, elles sont capables de gérer ces commutations à haute fréquence sans perdre beaucoup d'énergie en route. Cela signifie qu'une plus grande partie de la puissance parvient aux roues, là où elle est le plus utile, offrant des performances d'accélération impressionnantes que les constructeurs adorent mettre en avant dans leurs fiches techniques.

Optimisation de la durée de vie de la batterie grâce à une régulation efficace de la puissance

Les modules IGBT se distinguent particulièrement en matière de gestion efficace de l'énergie, ce qui contribue à prolonger considérablement la durée de vie des batteries des véhicules électriques. Ils fonctionnent en contrôlant la manière dont l'énergie est transmise aux éléments en mouvement de la voiture, réduisant ainsi la consommation électrique inutile et maintenant la batterie chargée pendant de plus longues durées. Des études ont démontré que les véhicules dotés d'une meilleure gestion de l'énergie préservaient leur santé batterie de manière significativement supérieure à ceux qui n'en disposent pas. Prenons par exemple la technologie EDT2 d'Infineon, qui réduit les pertes énergétiques lorsque le véhicule ne fonctionne pas à pleine capacité. Une telle innovation permet aux constructeurs automobiles de concevoir des VE capables d'assurer de longs trajets sans faiblir, tout en offrant des performances fiables jour après jour sur la route.

Permettre des architectures haute tension (750V-1200V)

Les véhicules électriques évoluent de plus en plus vers des systèmes haute tension, généralement compris entre 750 volts et 1200 volts, grâce notamment aux avancées technologiques dans les IGBT. Ce changement apporte de réels avantages en termes de performance, notamment une meilleure efficacité énergétique et une diminution globale de l'énergie perdue. Les modules IGBT eux-mêmes gèrent ces tensions élevées très efficacement, assurant une grande fiabilité du système tout en dissipant la chaleur plus efficacement que les anciennes conceptions. Lorsque les véhicules fonctionnent sous des tensions plus élevées, l'intensité circulant dans les câbles est en réalité réduite, ce qui entraîne des pertes I²R (I squared R) nettement plus faibles. Pour les constructeurs souhaitant optimiser l'autonomie de leurs batteries, cette amélioration fait toute la différence. C'est pourquoi de nombreux fabricants automobiles adoptent aujourd'hui ces configurations haute tension intégrant des IGBT comme partie intégrante de leur stratégie standard pour les plateformes de véhicules électriques.

Défis et Innovations dans la Mise en œuvre des IGBT

Dissipation de Chaleur dans les Applications Haute Puissance

La gestion de la chaleur reste l'un des plus grands défis pour les applications IGBT à forte puissance, en particulier dans le cas des véhicules électriques, où le fait de maintenir une température raisonnable est essentiel pour assurer à la fois les performances et la fiabilité. Lorsque la température devient trop élevée à l'intérieur de ces modules, on observe une baisse d'efficacité et parfois même des pannes complètes qui affectent le bon fonctionnement global du véhicule. Le secteur travaille activement à plusieurs solutions pour résoudre ce problème. Certaines entreprises étudient des interfaces thermiques améliorées entre les composants tandis que d'autres testent de nouvelles méthodes de refroidissement. Une approche courante consiste à intégrer des barrières thermiques durant la fabrication et à utiliser des matériaux permettant d'évacuer la chaleur plus rapidement. Ces améliorations permettent aux systèmes des véhicules électriques de fonctionner efficacement même sous forte charge, ce qui fait toute la différence pour les conducteurs souhaitant une performance fiable de leur voiture jour après jour.

Contraintes de taille versus exigences en puissance

Les fabricants font face à de réels défis lorsqu'ils tentent d'intégrer des capacités de puissance plus élevées dans des modules IGBT de plus en plus compacts pour les véhicules électriques. L'espace disponible à l'intérieur des VE est limité, ainsi les composants doivent être réduits tout en continuant à gérer l'électricité sans surchauffe ni défaillance. Certaines entreprises abordent ce problème en créant des modules miniaturisés offrant une densité de puissance plus élevée. Ces nouveaux designs incorporent des matériaux avancés permettant une meilleure dissipation de la chaleur et une meilleure conductivité électrique. Une excellente illustration de cela est l'utilisation du carbure de silicium (SiC) dans la construction des modules. Ce matériau permet aux ingénieurs de concevoir des IGBT qui occupent moins de place sur la carte électronique, tout en délivrant la même puissance que les unités traditionnelles plus grandes. Résultat ? Une intégration système globale améliorée et des performances accrues au sein du réseau électronique du véhicule.

Solutions de refroidissement avancées : refroidissement par ailettes et liquide

La dernière technologie de refroidissement, incluant des dissipateurs à ailettes et des systèmes de refroidissement liquide, fait toute la différence lorsqu'il s'agit de gérer la chaleur dans les modules IGBT à l'intérieur des véhicules électriques. Ces conceptions à ailettes offrent en réalité une surface beaucoup plus grande pour évacuer la chaleur excédentaire, surpassant largement les anciennes méthodes de refroidissement. Le refroidissement liquide pousse les choses encore plus loin en éliminant directement la chaleur provenant des composants IGBT eux-mêmes, les maintenant suffisamment frais pour supporter des charges électriques importantes sans surchauffer. Des tests en conditions réelles sur des systèmes EV réels ont démontré que ces améliorations de refroidissement pouvaient accroître les performances thermiques d'environ 30 % dans certains cas, permettant aux modules de fonctionner plus efficacement pendant de longues durées. Alors que les fabricants cherchent constamment à tirer plus de puissance et d'autonomie de leurs conceptions de véhicules électriques, ces avancées en matière de gestion thermique ne sont plus simplement utiles, elles deviennent absolument nécessaires pour répondre aux exigences des véhicules électriques modernes.

Conclusion – L'avenir des modules IGBT dans les véhicules électriques et l'électronique automobile

Les modules IGBT devraient transformer le fonctionnement des véhicules électriques à l'avenir, les rendant plus performants en matière de conversion d'énergie et fonctionnant de manière plus efficace. Ce que ces modules font essentiellement, c'est gérer le flux d'électricité dans les VE, ce qui signifie qu'ils aident les véhicules à parcourir des distances plus longues avec une charge tout en réduisant la chaleur résiduelle nuisible pour l'environnement. À mesure que les chercheurs continueront à améliorer la technologie IGBT, on peut s'attendre à des composants plus petits offrant davantage de puissance par watt. Cette tendance à la miniaturisation pourrait permettre aux constructeurs automobiles de concevoir des groupes motopropulseurs plus compacts, mieux intégrés sous le capot, et il est probable que cela contribuera également à réduire les coûts de fabrication lorsque les pièces deviendront plus simples à produire.

L'avenir semble prometteur pour les modules IGBT, car ils continuent de redéfinir les conceptions et les capacités des véhicules électriques. Les fabricants s'efforcent de résoudre des problèmes techniques anciens par le biais d'innovations telles que les systèmes de refroidissement direct par eau et les modules de taille réduite. Prenons par exemple Fuji Electric, qui a récemment lancé un modèle compact Module IGBT doté d'un refroidissement liquide direct, ce qui indique la direction que l'industrie pourrait prendre prochainement. Nous pouvons également nous attendre à voir davantage d'entreprises intégrer des capteurs avancés dans ces modules. Ces capteurs surveilleront les fluctuations de température et les niveaux de courant avec une bien meilleure précision, assurant ainsi une opération plus sûre et des performances améliorées dans l'ensemble des électroniques automobiles. En fin de compte, ce que nous observons actuellement avec la technologie IGBT prépare le terrain à des options de transport plus intelligentes et plus efficaces à l'avenir.

Section FAQ

Qu'est-ce que les modules IGBT, et pourquoi sont-ils importants dans les véhicules électriques ?

Les modules IGBT, ou Transistors Bipolaires à Grille Isolée, sont des composants cruciaux dans les véhicules électriques. Ils jouent un rôle important dans la conversion d'énergie, en convertissant efficacement le courant continu (CC) de la batterie du véhicule en courant alternatif (CA) nécessaire pour le moteur électrique. Cela garantit une utilisation efficace de l'énergie et une meilleure performance du véhicule.

Comment les modules IGBT améliorent-ils l'efficacité énergétique des véhicules électriques ?

Les modules IGBT améliorent l'efficacité énergétique en optimisant la gestion de l'énergie dans les véhicules électriques. Ils réduisent les pertes lors des commutations, ce qui aide à augmenter l'autonomie, à utiliser au mieux l'énergie de la batterie et, finalement, à réduire la consommation d'énergie.

Quels progrès sont réalisés dans la technologie IGBT ?

Les progrès actuels dans la technologie IGBT se concentrent sur la réduction de la taille tout en augmentant la densité de puissance et l'efficacité. Les développements tels que l'utilisation de matériaux à large bande interdite comme le carbure de silicium, ainsi que les innovations en gestion thermique, contribuent à une meilleure performance et à des conceptions plus compactes.

Table des Matières

- Introduction : Le rôle pivot des modules IGBT dans la technologie EV

- Fonctions principales des modules IGBT dans les véhicules électriques

- Principaux Avantages des Modules IGBT pour les Véhicules Électriques

- Impact des modules IGBT sur les performances des VE

- Défis et Innovations dans la Mise en œuvre des IGBT

- Conclusion – L'avenir des modules IGBT dans les véhicules électriques et l'électronique automobile

- Section FAQ