Қалай IGBT модульдері Шовдаушылық қызмет ететіндерін жоғарлату

Точтамалық дуга қонтролі үшін жылдам ауыстыру

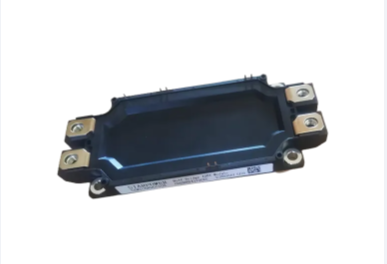

IGBT модульдері қазіргі заманғы пышақтау процесстерінде өте маңызды рөл атқарады, себебі олар пышақтау доғасын әлдеқайда дәл басқаруға көмектесетін жылдам ауыстыру жылдамдықтарын қамтамасыз етеді. Бұл модульдер тез ауыстырған кезде пышақтау доғасының тұрақтылығы сақталады, ол жалпы алғанда жақсы сапалы пышақтау нәтижелерін береді. Дәстүрлі әдістер кемшіліктердің әртүрлі түрлерін жасауға ұмтылады, бірақ IGBT технологиясы арқылы осындай мәселелерді біраз азайтып, сонымен қатар бүкіл процессті жылдамдатуға болады. Доғаны басқарудің жақсаруы пышақтаулардың бетінің тегістелуіне де әкеледі, соның арқасында қуыстар мен трещинкалар сияқты мәселелер азаяды, бұл жұмыстың сапасын бүлдіреді. Салалық деректер IGBT модульдерін пайдаланатын пышақтау операцияларының бұрынғы технологияларға қарағанда шамамен 30% жылдам болып табылатынын көрсетеді. Уақыт шектеулеріне қарсы жұмыс істейтін өндірушілер үшін осындай өнімділік артуы жоспар бойынша мерзімде шығаруды қамтамасыз етеді, өнімдер сапа стандарттарынан азайтуға жол бермей отырып.

Инверторлік системаларда энергия терістерін азайту

IGBT модульдері инверторлы қосқыштарды пайдаланатын дәнекерлеу жүйелерінде энергия тиімділігіне үлкен әсер етеді, себебі олар энергия шығынын азайтады. Бұл модульдер жалпы энергия пайдалануды шамамен 20% дейін үнемдеуге көмектеседі, ол зауыт иелерінің кәсіпорынның табысында да, сонымен қатар көміртегі ізін азайтуда да байқалады. Қазіргі дәнекерлеушілер үшін IGBT модульдерінің жақсырақ жұмыс істеуі электр энергиясының аз пайдаланылуына байланысты жұмыс құнының төмендеуін білдіреді. Өнеркәсіптегі жағдайға назар аударсақ, компаниялар модульдерге ауысқан кезде нақты ақша үнемдеу туралы хабарлайды, ерекше айтқанда ай сайынғы электр сыйақтарында. Үнемдеу тек кестедегі сандармен ғана шектелмейді, олар өндірушілерге жабдықтарды жаңарту немесе бағаларды көтермей-ақ пайда арттыру мүмкіндігін береді.

Компакт жұмбақтау жабдықтарында қоршаған құрылғылардың құрамын оптималашудың

IGBT модульдері өндірушілерге кішігірім қораптарға көбірек қуат сыйғызуға мүмкіндік береді, яғни олар кеңістікті аз алатын және салмағы жеңіл болатын дәнекерлеу жабдықтарын жасай алады. Сапаны азайтпай, мобильді дәнекерлеу шешімдеріне қажеттілігі бар құрылыс алаңдары мен жөндеу шеберханалары үшін осындай жетілдірулердің маңызы зор. Жұмыстың қиын орындарында немесе жұмыстар арасында жабдықты түсіру/жүктеу кезінде кеңістікті үнемдеу ерекше маңызды. Infineon компаниясының IGBT өнімдерін мысалға келтірейік – кәсіпорындар дәнекерлеу беріктігі мен тұрақтылығы төмендемейтін жоғарылатылған тасымалдану мүмкіндігі туралы хабарлайды. Зауыттар өз аумақтарын кішірейтіп, шығарындылар көлемін кеңейте түскен сайын, IGBT технологиясы арқылы дәнекерлеу жүйелерін кішірейтіп жасау мүмкіндігі заманауи өндірістің әртүрлі секторлардағы цехтардың жағдайларына қаншалықты икемді әрі жан-жақты түрде жауап бере алатынын көрсетіп отыр.

Салмақта IGBT модульлерінің негізгі техникалық плюстары

Қосымша Жауаптылық Индустриялық Қолданбалар үшін

Өндірістік ортада пісіру жасау кезінде құрылғылардың кернеуді қаншалықты жақсы ұстай алатыны маңызды рөл атқарады. Осы жерде ИБТ модульдері шығып табылады. Бүгінгі таңда нарықтағы басқа да көпшілік таңдауларға қарағанда жоғары кернеуді басқару жөнінде осындай компоненттер өте жақсы жұмыс істейді. Электр жүйелерінен тұрақты жұмыс істеу талап етілетін қиын жағдайларда олардың беріктігі байқалады. Күшті электроника саласындағы сараптамалардың соңғы нәтижелері ИБТ-тердің ескірген технологияларға қарағанда жоғары кернеу деңгейін басқара алатынын көрсетті, мысалы, МОПТ және БЖТ сияқты технологиялар, яғни жағдай қаншалықты қиын болса да олар жұмысын жалғастыра береді. Осындай модульдермен жұмыс істеген инженерлердің көбі кернеуді дұрыс басқару маңызды болып табылатын жобалардағы сәтті нәтижелерді атап көрсетеді. ИБТ-тер кернеуге қатты талаптар қойылатын жағдайлармен де күресе алатынына сенімді, қауіпсіздікті және тиімділікті жоғалтпай өз өндірістерін жетілдіргісі келетін зауыттар үшін олар танымал компоненттерге айналып отыр.

Непрерывное жұмыс ішінде төмен шаруашылық зерттеулер

Барлық электр жүйелері біз өткізу шығындары деп атайтын нәрсеге ұшырайды, бірақ IGBT модульдерін пайдалану осы шығындарды біраз азайтады, бұл дәл соның арқасында дәнекерлеу жүйелерін ұзақ уақыт бойы тұрақты жұмыс істеуі үшін маңызды. Негізінде, бұл шығындар электр тогы жартылай өткізгіш материалдар арқылы өткен кезде кедергіге тап болғаннан туындайды. IGBT модульдері бұл мәселені ескі жартылай өткізгіш технологияларына қарағанда ә существенно азайтатыны сол жағынан жақсы. Сондықтан энергия одан да тиімді пайдаланылады. IGBT-ке ауысқан өндірушілер өз кәсіпорындарында нақты үнемдеу нәтижелерін бақылаған. Мысалы, автомобиль өндірісі зауыттарында көптеген жерлерде шығындардың энергетикалық көрсеткіштері түбегейлі төмендегенін, өндіріс көлемін сақтап қалғанын байқауға болады. Ақшаны үнемдеудің өзінде де модульдер дәл соның арқасында дәнекерлердің беріктігін арттырады, сондықтан көп көлемді өндіріс жүргізетін зауыттар үшін олар қажетті жабдық болып табылады.

PWM Контроль Стратегиясымен Қамтитындылық

IGBT модульдері PWM басқару әдістерімен өте жақсы жұмыс істейді, бұл оларға бүгінгі дәнекерлеу технологиясында үлкен артықшылық береді. PWM құрылғысы барлық заттарды басқаруды басқарады. Бұл параметрлерді жақсы бақылаусыз, дәнекерлеу сапасы тез төмендейді. IGBT-тер PWM жүйелерімен бірқалыпты интеграцияланған кезде дәнекерлеушілер оларды әр түрлі жұмыстарға қажеттіліктеріне сәйкес баптай алады, бұл барлық жағынан жақсы дәнекерлеуді білдіреді. Өнеркәсіптік мамандар жиі сол дәнекерлеу параметрлерін PWM арқылы өзгертуге мүмкіндік беру орташадан керемет нәтижелерден ажырататынын атап көрсетеді. Біз бұл пайданы көптеген салаларда, соның ішінде көліктер, электр қуатын өндіру жабдықтары, тіпті күнделікті пайдаланатын құрылғыларда да көріп отырмыз. IGBT-тердің PWM-мен жақсы ойнауы олардың ең жоғары сапалы дәнекерлеуді сақтау үшін дүкендерде стандартқа айналып бара жатқанын көрсетеді.

IGBT-Бойынша Жұмыс Істемелеріне Арналған Термик Басқару Шешімдері

Ултты температуралық әрекеттер үшін қалайтын жылықты тасымалдау әдісі

Дәнекерлеу операциялары кезінде жабдықтың ұзақ уақыт бойы қаншалықты тұрақты жұмыс істейтіндігі дәнекерлеу қондырғыларын салқындату тиімділігіне байланысты. Олардың көпшілігі изоляцияланған ажыратқыштың биполярлық транзисторы немесе IGBT модульдерін пайдаланады. Жақсы салқындату әдістері маңызды, өйткені бұл процесстер қатты қызуын тудырады. Сұйық салқындату жүйесін дұрыс радиаторлармен қосып қарастырыңыз - бұл жүйелер артық жылуды проблема туғызбай тез арада шығарып тастауға көмектеседі. Айырмашылық тез сезіледі; дұрыс термиялық басқаруды енгізген жөндеу орындары жиі өз жарамсыздық көрсеткіштерінің 30% төмендегенін байқайды. Дәнекерлеушілер сапалы салқындату опцияларына қаржы салған сайын олардың машиналары жиі тоқтап тұрмай тұрақты жұмыс істейді. Бұл жабдықтың қызмет ету мерзімін ұзартады. Ал күнделікті жөндеу жұмыстарымен айналысып жүргенде қосымша ақша төлеп, жабдықты ауыстыруға ешкімнің қажеті жоқ. Сенімді нәтижелер алу үшін дұрыс температураны басқару әрқашан маңызды.

Модуль дизайнында жылық қарым-қатынасын оптимал Lau

Қашан болса IGBT модулі жобалау, жылуға төзімділік модульдердің дәнекерлеу қолданбаларында қаншалықты ұзақ уақыт пайдаланылатынын анық әсер ететіндіктен, басымдықтың ең жоғарғы деңгейінде қалып табылады. Жылуды электроника элементтерінен алыстатыру жүйесінің жұмыс істеуінде айтарлықтай айырмашылық жасайды. Қажетті жағдай орындалған кезде модульдер суық болып қалады, сондықтан күтпеген жерден қызып кетіп, істен шықпайды. Соңғы кезде өнеркәсіпте біраз қызықты жетілдірулер болды. Өндірушілер әртүрлі материалдық қабаттармен тәжірибе жасап, жылытуды басқару бойынша тиімді шешімдер әзірлейді. Бұл өзгерістер модульдердің тек жақсы жұмыс істеуін ғана емес, сонымен қатар пайдалану мерзімін ұзартады. Аз уақыт бос болуы дәнекерлеу цехтарында өндірістің үздіксіз жұмыс істеуіне қажетті шығындардың азаюын білдіреді.

Талапты қосымша жобалау циклдерінде жылысырлықты аzaу

Осындай күшті пісіру циклдарын орындау кезінде IGBT модульдерінің қызып кетуін болдырмау үшін өте ақылды әдістер қажет. Қазіргі кезде көптеген жүйелерге модульдің ішінде не болып жатқанын бақылайтын жылу датчиктері мен кері байланыс жүйелері енгізілген. Бұл бақылау жүйелері жылу деңгейлерін үнемі тексеріп, проблемалар пайда болардан бұрын қажетті түзетулер енгізе отырып, жүйенің тиімді температурада жұмыс істеуін қамтамасыз етеді. Саладағы мамандар бұл түрдегі ықтимал қызуға қарсы шаралардың уақытылы қабылдануы жөндеуге кететін шығындарды азайтып, жүйенің тоқтау уақытын қысқартатынын көзбен көрген. Жақсы қызуға қарсы қорғау жүйесін енгізу арқылы жұмысшылар маңызды жұмыстар орындалып жатқан кезде жабдықтардың істен шығуына байланысты күтіп қалмайды. Нәтижесінде қысымды жағдайларда жұмыс істеу кезінде әр минуттың маңызы бар болған жағдайда жалпы өнімділіктің артуына қол жеткізеді.

IBGT Жұлдыздар Технологиясындағы Келешекті Инновациялар

Қызметкерлікке Силезий Карбид (SiC) Гибрид Модульдері

Кремний карбиді немесе SiC гибридті модульдер әртүрлі салаларда пайдаланылатын дәстүрлі кремнийлі IGBT модульдеріне қарағанда тиімділігі мен жылуға төзімділігі жағынан асып түседі, сондықтан пайдалану олардың дамуына себепші болуы мүмкін. Олардың ерекшелігі – бұл кіші кеңістікте көбірек қуатты ұстап тұрады және қирауға ұшырамайтын жоғары температураға төзімділігі, яғни жабдықтың жөндеу аралығы ұзақтау болады және ұзақ мерзімде жөндеуге кететін ақшаны үнемдейді. Көптеген дәнекерлеу шеберханалары соңғы кезде SiC технологиясына ауысуда, өйткені тұтынушылардың ұзақ қызмет ететін және энергияны көп шығынбайтын жүйелер сұрауы күшейіп барады. Нарықтық талдаушылар компаниялар дәнекерлеу жүйелерін жетілдірген сайын бұл модульдердің әлемдік нарығында үлкен өсу болады деп болжам жасайды. Қазіргі уақытта жүру бара жатқан бұл жетілдірулер SiC-ті дәнекерлеу технологияларының дамуындағы келесі қадам ретінде қарастыруға болатынын көрсетіп тұр.

Предиктивті сақтау үшін зерттеу жүйелері

IGBT деген жетектелетін дәнекерлеуіштерге интеграцияланған ақылды бақылау жүйелері қазіргі кезде дәнекерлеу технологиясында болып жатқан ең маңызды жетілдірулердің бірі болып табылады. Бұл жүйелер жабдықтардың өнімділігін үнемі бақылап отырады, сондықтан техникалық қызмет көрсету бригадалары ақаулар пайда болғанға дейін оларды жөндеуіне болады. Болжамды қолданбалы техникалық қызмет көрсету мәселесіне келсек, зерттеулер осындай бақылау нәтижесінде машиналардың қызмет ету мерзімі ұзақ болатынын көрсетті. Кейбір хабарламаларда тіпті әртүрлі өндірістік орталарда тұрақты жұмыстың 20% азайғаны туралы айтылған, бұл ұзақ мерзімде ақшаны үнемдеуге әкеледі. Әр күні дәнекерлеу операцияларын жүргізіп тұратын цехтар үшін осындай күрделі бақылау құралдарының болуы жұмыстың тоқтаусыз және жұмыс үрдісінің тегіс болуын қамтамасыз етеді. Сол себепті көптеген компаниялар дәнекерлеу жабдықтары үшін ақылды бақылау шешімдеріне инвестиция салудың пайдасын көре бастады.

Келешекке арналған көзделу модулдерін экологиялық өндіріс

Қазір біз компаниялар жасыл өндірістік әдістерге ауыса бастаған кезде дәл осы уақытта дәнекерлеу саласында нақты өзгерістер болып жатқанын байқап отырмыз. Барлау кәсіпорындары дәнекерлеу модулі өндіріс жолдарында қалдықтарды азайтуға және қоршаған ортаны қорғайтын материалдарды пайдалануға тырысып жатыр. Қызықтысы, бұл енді жаңа технологиялар туралы ғана емес, сонымен қатар планетаның болашағы туралы шынайы қам-қаб concern көрсетіп отыр. Салалық деректердің өзі сектордағы адамдардың көпшілігі жасыл істерді қолдайтынын көрсетіп отыр, бұл жақсы репутацияны қалыптастыруға және тұрақты тұтынушыларды сақтап қалуға көмектеседі. Алда болашақта дәнекерлеу модулдері ықтимал тұрақтылық тенденцияларын жалғастыруға бағдарланған, сапаны және өнімділікті қамтамасыз ете отырып, инновациялық технологиялар мен жауапты экологиялық тәжірибелердің қиылысу нүктесін табуға тырысады.

Сұрақтар мен жауаптар бөлімі

IGBT модульдері дегеніміз не?

IGBT модульлері, немесе Изоляциялық Қапыршақ Биполяр Транзистор модульлері, жауып қызметтерінің күштілігін арттыру мақсатында пайдаланылатын semiconductor құрылғылар. Олар ыстық қалдыруын кемиді және power density-ны оптималастыру үшін жылдам алмастыруы бар.

IGBT модульлері қалыптау күштілігін қалай жоғарылады?

Олар точное дуга қабылдауы үшін жылдам алмастыру қабілетін береді, осылайша қалыптау сапасын арттырады. Олар энергия сақтауын inverter-базалы системаларда кемиді және compact қалыптау құрылғысының дизайнін қолдауға болады.

IGBT модульлерінің қалыптаудағы пайдасы қандай?

Пайдалары superior voltage handling, төменгі conduction losses және PWM қабылдау стратегиясымен сәйкесше, барлық бұл performance және достықты қалыптауға және достыққа қолдау береді.

IGBT модулдері қысқау жобаларында қандай rol ойнайды?

IGBT модулдері арнайы суыңғыштық техникалық тәсілдерден рөл алады және термик көрсеткіштердің оптималды дизайнімен қысқауға мүмкіндік береді, бұл жеңіл шоғырлануға қарсы қолданылатын жабдықтардың өмірін ұзартады.

IGBT сварочтық технологиясына қатысты болашақтағы інновациялар бар ма?

Иә, болашақтағы інновациялар Силикон Карбид (SiC) гибрид модулдерін пайдалану және прогнозтық сақтау үшін зерттеу жүйелерін интеграциялау қосымшасында.