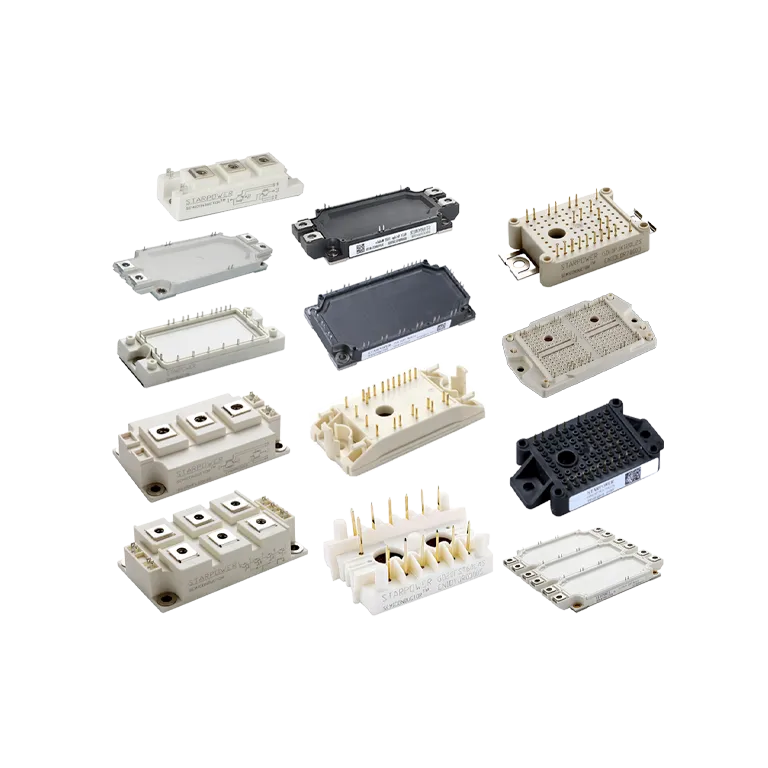

IGBT-ის მოდულები, რომლებიც წარმოადგენს გამოყოფილი შესასვლელის ბიპოლარული ტრანზისტორების სტანდარტს, ძლიერი ელექტრონიკის საქმეში მნიშვნელოვან როლს თამაშობს. ეს პატარა მუშა ცხოვრებაში ასრულებს ორ საქმეს ერთდროულად, ის ეფექტურად უნდა ჩართოს და გამორთოს ელექტროენერგია, ასევე უნდა მოახდინოს დენის მიმდინარეობის კონტროლი. წარმოიდგინეთ, რომ ისინი აერთიანებენ MOSFET-ების საუკეთესო ნაწილებს (რომლებიც სწრაფად გადართვას ახდენს) ბიპოლარული ტრანზისტორების ძალებთან (განსაკუთრებით დიდი დენის მართვაში). ეს ხდის IGBT-ებს სრულიად შესაფერისს ელექტროენერგიის დიდი რაოდენობის მართვისას. მზის პანელების, ქარის ფერმების და ელექტრომობილების მიმართ ამჟამად არსებული დიდი აზრის გამო, მაღალხარისხიანი IGBT მოდულები ჩვენი სამომავლო სამარაგე სისტემებისთვის აუცილებელ ელემენტად იქცა. მათ გარეშე აღდგენითი ენერგიის სისტემები ვერ იმუშავებდა სწორად. როდესაც ვსაუბრობთ განახლებადი ენერგიის გადასვლის შესახებ, ეს მოდულები არის როგორც უხილავი გმირები ფონზე. მათი მუშაობის პრინციპის გაცნობიერება საშუალებას გვაძლევს სისტემების უკეთ დიზაინში და გონივრულ მომსახურების მიმართულებით გადახატვაში. იმ ინდუსტრიებს, რომლებიც ყურადღებით უზრუნველყოფენ IGBT-ების სანდო მუშაობას, ხშირად ხანგრძლივი მოწყობილობების ვადას და სისტემის მუშაობის საერთო გაუმჯობესებას უზრუნველყოფენ.

Სამუშაო IGBT მოდულების გავრცელებული წარმოქმნის პირობები

IGBT მოდულები ძირითადად არის მნიშვნელოვანი სამუშაო ძალის ელექტრონიკაში, მაგრამ მათ ხშირად მიერთვება განსხვავებული წარმოქმნის პირობები, რომლებიც შეიძლება ძალიან გავლენა ახდენონ მათ მუშაობაზე. ამ პირობების გასაგება დახმარება წარმოქმნის პრევენციაში და მოდულის მუშაობის გამართლების გაუმჯობესებაში.

TERMIC გამოვიდება IGBT მოდულებში

Ტემპერატურული გარბოლი წარმოადგენს ერთ-ერთ უარეს ვარიანტს, რაც შესაძლოა მოხდეს IGBT მოდულების შემთხვევაში. როდესაც ტემპერატურა იზრდება არაკონტროლირებულად, ეს სერიოზულად შეიძლება დააზიანოს ან სრულიად გაანადგუროს ეს კომპონენტები. ყველაზე ხშირად ეს ხდება გაგრილების სისტემების არასათანადო მუშაობის ან სითბოს მართვის არასწორი მართვის გამო. ზედმეტი სითბოს მოცილება აქ ძალიან მნიშვნელოვანია. ინდუსტრიული მონაცემები აჩვენებს, რომ IGBT-ების დაზიანებების დაახლოებით ნახევარი სითბოს პრობლემებთან არის დაკავშირებული. ეს რიცხვები ნათლად აჩვენებს, თუ რატომ უნდა იყოს სითბოს მართვა მნიშვნელოვანი ელემენტი როგორც ამ მოდულების დიზაინში, ასევე მათ შენარჩუნებაში დროის განმავლობაში. გონივრული სითბოს გეგმარება აცილებს სისტემის სრულ გადახურვას.

Განსაზღვრული ვოლტის წვდომა და გადაწყვეტა

Როდესაც ძაბვის ზედმეტი დატვირთვა ახდენს ზემოქმედებას IGBT მოდულებზე, ხშირად იწვევს სერიოზულ პრობლემებს, როგორიცაა კარიბჭის ოქსიდის გატეხვა, რაც სრულ მოდულის მარცხს იწვევს. ამ პრობლემების უმეტესობა გამოწვეულია არასასურველი ძაბვის შეტევებით და ამასთან, მკაცრი ძაბვის შეხვევებით, ამიტომ ძაბვის დაცვა აბსოლუტურად აუცილებელია მოდულების სწორად მუშაობის შესანარჩუნებლად. კვლევები აჩვენებს, რომ snubber წრედების დამატება ხელს უწყობს ძაბვის დაკავშირებული მარცხების შემცირებას, შესაძლოა მონაცემების თანახმად დაახლოებით 40%-ით. ნებისმიერისთვის, ვინც მუშაობს IGBT-ებთან, გადატვირთვის ძაბვის დაცვა არ არის მხოლოდ სასურველი, არამედ სავალდებულოა, თუ გვინდა, რომ მოდულები გამძლეობით გაიარონ მათი გამოყენების ვადა მუდმივი ჩანაცვლებების გარეშე.

Მოკლე შეკრების ვერახლებები

Როდესაც IGBT მოდულები გამომდინარეობს მოკლე წრეში, ეს ნიშნავს, რომ ელექტროენერგია იპოვის არასასურველ გზას ძალიან მაღალი დენის გავლით, რაც შეიძლება მუდმივად დაზიანდეს კომპონენტები. ეს ამაღლებული ხრიკები ხშირად აღემატება მოდულის დასაშვებ ზღვარს, ამიტომ საჭიროა კარგი დამცავი წრეების არსებობა. ინდუსტრიული მონაცემების მიხედვით, ყველა IGBT პრობლემის დაახლოებით ერთი მესამედი მოდის ამგვარი მოკლე წრეების ინციდენტებიდან. ამიტომ ბევრი ინჟინრის დრო ხარჯავს სისტემის მოწყობილობის მკაცრად დაკვირვებას და დამცავი ზომების გატარებას ელექტროენერგეტიკული მოწყობილობების მთელ სისტემაში. ამის სწორად გაკეთება არ არის მხოლოდ გასატეხიანობის თავიდან აცილება - სწორად განხორციელებული დაცვა უზრუნველყოფს იმ ძვირი IGBT მოდულების გრძელ ვადაში მუშაობას შეცვლებს შორის და ამცირებს ხარჯებს მანქანამშენებლობის საწარმოებში.

IGBT მოდულების წარდგენის განსაზღვრა

Გამყარების ინდიკატორები და თერმალური მონიტორინგი

Იმის გაკონტროლება, თუ როგორ იხტომება სითბოს დონე, ძალიან მნიშვნელოვანია IGBT მოდულების გადახურების პრობლემების ადრე აღმოჩენის დროს. სადაც მოდულებში სითბო იხტომება, ამ ადგილების დასადგენად ახალგაზრდული მოწყობილობები, როგორიცაა ინფრაწითელი კამერები და ტემპერატურის სენსორები გვეხმარება. კვლევები აჩვენებს, რომ იმ კომპანიებს, რომლებიც ტემპერატურის სისტემატიურად შემოწმებას ახორციელებენ, შესაბამისად მათი შენარჩუნების სამუშაოები დროის განმავლობაში დაახლოებით 70%-ით უფრო ეფექტური ხდება. ასეთი პრობლემების წინასწრებით აღმოჩენა ნიშნავს დაზიანებული ნაწილების დაუყოვნებლივ შეკეთებას, რაც კიდევ უფრო მეტი არაგათვალისწინებული სარემონტო ხარჯების დაზოგვას უზრუნველყოფს და ასევე უზრუნველყოფს მოდულების საცავი ვადის გახანგრძლივებას.

Ელექტროარკი და ინსულაციის დეგრადაცია

Როდესაც ელექტრული განწყვეტის შედეგად წარმოიქმნება ნათურის გარდატეხილი, ჩვეულებრივ ნიშნავს, რომ მოწყობილობის შიგნით იზოლაცია იწყებს დაშლას რაიმე ადგილას. მოდულების გარშემო დამცავი ფენები დაზიანდება ასეთ დროს. ნებისმიერმა, ვინც მუშაობს ელექტრულ სისტემებთან, უნდა განახორციელოს რეგულარული შემოწმება საშუალებების დაზიანების ნიშნების დასადგენად პერიოდული შემოწმების დროს. ყურადღებით შეამოწმეთ დაკავშირების წერტილები და დაწვის ადგილები და ყურადღება მიაქციეთ უცნაურ ბუზინის ხმებს, რომლებიც მოწყობილობის კასეტებიდან მოდის. იზოლაციის ტესტირების სწორი პროცედურების მიმდევრობა უზრუნველყოფს არაგონივრული მავნე მოვლენების შემცირებას და იმ კრიტიკული დამცავი ბარიერების სწორ მუშაობას. მოდულებს, რომლებიც ინარჩუნებენ კარგ იზოლაციის თვისებებს, ხშირად შესაძლოა გაუმჯობესებული გამძლეობა ჰქონდეთ და შესაბამისად შეუძლიათ თავიდან აიცილონ ხარჯებიანი დასვენების სიტუაციები, რომლებიც ოპერაციებს აშლაგავს.

Ფუნქციონალური დახრელობის და მეტრიკების გამორჩენა

Მნიშვნელოვანი სამუშაო ინდიკატორების, როგორიცაა გადართვის სიჩქარე, კვების წყაროს დენის დონეები და გაჯენების ძაბვა, დროულად აჩვენებს იმას, თუ როდი იწყებს IGBT მოდულები თავისი ეფექტურობის დაკარგვას. სწორი დიაგნოსტიკური ტესტირების მეთოდი აუცილებელია ასეთი პრობლემების დროულად ასაცნობად, სანამ ისინი სერიოზულ პრობლემებად გადაიზარდება. ინდუსტრიული მონაცემები აჩვენებს, რომ პერიოდული შემოწმებებით შესაძლოა დაფიქსირდეს დაახლოებით 60% პოტენციური გამართულება წინასწარ. ეს კი უზრუნველყოფს მოდულების უწყვეტ და სანდო მუშაობას მათი სამსახურის ვადის განმავლობაში და არ დაუშვებს მათ გაუფრთხილებელ გამართულებას.

IGBT მოდულების ვადების პრევენციის მეთოდები

Მოწინავი გამყოფი სისტემები და თერმალური მართვა

IGBT მოდულებში თერმული გაუმჯობესების მართვა თერმული გაუმჯობესების პრობლემების შესაჩერებლად ძალიან მნიშვნელოვანია. სითხით გაგრილების სისტემები და სწორად დაყენებული გამაგრილებელი რადიატორები მნიშვნელოვნად ამცირებს გახურვის ალბათობას, რაც ხშირად იწვევს მოდულების მოშლას მომდევნო ეტაპებში. როდესაც სითბოს მართვა ხდება სწორად, ეს მოდულები საუკეთესო ტემპერატურულ რეჟიმში მუშაობენ გრძელი დრო, ამიტომ ისინი საშუალოდ უფრო მეტი ხანი გრძელდებიან. კვლევები აჩვენებს, რომ მწარმოებლები, რომლებიც ასევე ახორციელებენ გაგრილების უფრო ხარისხიან ტექნოლოგიებს, აღიარებენ გახურვით გამოწვეული მოშლების რაოდენობის დაახლოებით ნახევრად შემცირებას. ეს სისტემის საიმედოობისთვის და ელექტრონიკის მუშაობისთვის რეალურ პირობებში საშუალოდ მნიშვნელოვან განსხვავებას ქმნის.

Ვოლტაჟის რეგულირება და სნაბერი წირები

IGBT მოდულებზე ძაბვის რეგულირების სისტემების დამატება სნაბერ წრედებთან ერთად დახმარებას აძლევს იმ არასასურველი ძაბვის შეტევებისა და გადამდინარეების წინააღმდეგ, რომლებიც ხშირად ხდება. ამ კომპონენტების მუშაობის მეთოდი სინამდვილეში საკმარისად მარტივია, ისინი შთანთქავენ ზედმეტ ენერგიას და შემდეგ ამას ამართლებენ სანამ ის მოდულზე ნამდვილად ზიანს მიაყენებს. ამ მიდგომას საკმარისი რაოდენობის კვლევებიც უჭერს მხარს. რამდენიმე შემთხვევის შესწავლა აჩვენებს, რომ მწარმოებლების მიერ სნაბერ წრედების დიზაინში შეტანის შედეგად მოდულების გამართული მუშაობის მაჩვენებელი მნიშვნელოვნად იკლებს. ეს საკმარისად ლოგიკურია, თუ გავითვალისწინებთ იმას, რაც ხდება ნორმალური ექსპლუატაციის დროს. ელექტრონული მოწყობილობების საინჟინრო დიზაინით დაკავებული სპეციალისტებისთვის ასეთი დამცავი ზომების განხორციელება ნიშნავს ნაკლებ მომლოდინე ძაბვის ზიანს დროთა განმავლობაში. და უნდა აღინიშნოს, რომ არავინ უნდობს ხარჯოვანი მოდულების გამოცვლას რისიმე გამოწვეული ზიანის გამო, რასაც შესაძლოა თავიდან ევარჯიშა სწორი დიზაინის არჩევანით.

Დაცული წირები გამავალი მიმდინარე პირობების წინააღმდეგ

IGBT მოდულებში გადატვირთვის დროს არსებული საფრთხეების შესამცირებლად დამცავი წრედების, როგორიცაა დანადგარები და წრედის შემხვეტებელი მოწყობილობების ჩართვა მნიშვნელოვან როლს ასრულებს. როდესაც ხდება გადატვირთვა, ეს უსაფრთხოების მექანიზმები იწყებს მოდულის ელექტრომომარაგების გასატეხ სისტემებს სერიოზული ზიანის მომავლამდე. მრეწველობის მონაცემები აჩვენებს, რომ სწორი დამცავი წრედების დამატებით შესაძლოა შემოკლდეს მოკლე წრედების პრობლემები დაახლოებით 30 პროცენტით ბოლოდროინდელი კვლევების მიხედვით. მწარმოებლებისთვის, რომლებიც მუშაობენ სხვადასხვა სექტორში, ავტომობილიდან დაწყებული აღდგენითი ენერგიის სისტემებით დამთავრებული, ასეთი დაცვა ყველაფერს განსაზღვრავს. მოდულები, რომლებზეც დამცავი თვისებები კარგად არის დაყენებული, გრძელ ვადაში გამძლე და დატვირთულ პირობებში უკეთ მუშაობს. კომპანიები, რომლებიც ახორციელებენ ხარისხიანი წრედის დაცვაზე ინვესტიციებს, არ მხოლოდ სარემონტო ხარჯებს ზოგავს, არამედ უზრუნველყოფს მუდმივ მუშაობას კრიტიკულ გამოყენებებში, სადაც შეჩერება საერთოდ არ არის დასაშვები.

IGBT მოდულის მართვის უკეთესი პრაქტიკები

Რეგულარული შემოწმება და დიაგნოსტიკური ტესტი

IGBT მოდულების გლუვად მუშაობის უზრუნველსაყოფად საჭიროა მათი გამომცდელი ტესტირება და სრული შემოწმება. ასეთი პროცედურები უზრუნველყოფს მუშაობის გლუვად გაგრძელებას და პატარა პრობლემების დიდ გაუმართლებებამდე ადრე აღმოჩენას. თანამედროვე დიაგნოსტიკური მოწყობილობები გახდა არაჩანსაცვლებელი ინსტრუმენტი ტექნიკოსებისთვის, რომლებმაც უნდა შეამჩნიონ პრობლემური ადგილები უკვე ადრეულ სტადიაში. უმეტეს დაწესებულებებში ასეთი შემოწმებები ტარიღების განსაზღვრული გრაფიკის მიხედვით ხორციელდება, რაც სტანდარტული ინდუსტრიული პრაქტიკის შესაბამისად ხდება. ამ გრაფიკის დაცვა უზრუნველყოფს როგორც მუშაობის გლუვად გაგრძელებას, ასევე ხელს უწყობს ამ ძვირი მოდულების გამძლეობის გაზრდას მათი შეცვლის საჭიროებამდე.

Ოპტიმალური მომსახურების პირობები

Ის, რომ IGBT მოდულები მუშაობს კარგ გარემოს პირობებში, მნიშვნელოვანწილად განაპირობებს მათ მომსახურების ხანგრძლივობას და მათ შესრულებულ შრომას. როდესაც არსებობს ზედმეტი ტენიანობა ან როდესაც ტემპერატურა ხშირად იცვლება მაღალიდან დაბალზე, ეს მოდულების სწრაფ გამოსახილულებას იწვევს, რაც ნიშნავს იმას, რომ ისინი უფრო ადრე გამოვა სამუშაოდ. ამიტომ უმეტეს შემთხვევაში საჭიროა დამაგრდა კლიმატური კონტროლის სისტემების დაყენება. ეს სისტემები მხოლოდ ტემპერატურისა და ტენიანობის დონის შენარჩუნებით არ შეიზღუდება, არამედ მათი მუშაობის დროს ამაღლებს მოდულების საიმედოობას და გახანგრძლივებს მათ მომსახურების ვადას. იმ ინდუსტრიული აპლიკაციების შემთხვევაში, სადაც შეჩერება ფულს უტაცებს, შესაბამისი გარემოს მართვაში ინვესტიციები მოგებით იწევს.

Ელექტრო-მექანიკური გამატების გაუმჯობესება

Ის რომ იგბტ მოდულები ელექტრულ და მექანიკურ სპეციფიკაციებში მუშაობდნენ, დახმარებას უწევს საფრთხის შემცველი გადატვირთვის მდგომარეობების ასარიდებლად. როდესაც სპეციალისტები ამ რჩევების მიხედვით მოქმედებენ, ზოგადად აღმოაჩენენ, რომ მოდულები უფრო მეტი ხნის განმავლობაში გრძელდება და უკეთ მუშაობს. ნებისმიერმა ადამიანმა, რომელიც ამ კომპონენტებთან მუშაობს, უნდა მიიღოს შესაბამისი სწავლება, რომ დროულად შეძლოს გადატვირთვის პოტენციური პრობლემების ამოცნობა, სანამ ისინი სერიოზულ პრობლემებად გადაიქცევა. მრეწველობის მონაცემები აჩვენებს, რომ იმ კომპანიებს, რომლებიც მკაცრად ასრულებენ მწარმოებლის სპეციფიკაციებს, დაახლოებით 40%-ით ნაკლები მავნე მოდულის უარყოფა აქვთ იმ კომპანიებთან შედარებით, რომლებიც ახარჯივებენ პროცედურებს. ეს არ უზრუნველყოფს მხოლოდ უსაფრთხოებას, არამედ ეკონომიურად საინტერესოა მანქანების შეცვლისა და დასვენების ხარჯების შესახებ მომლოდინე მასშტაბით.

Დასკვნა: ძირითადი სტრატეგიები IGBT-ების გრძელვად მუშაობისთვის

Ის რა იმის გაკეთება, რომ IGBT მოდულები უფრო მეტი იმუშაოს, ნიშნავს იმ პრობლემების წინასწრებით მოგვარებას, სანამ ისინი დიდ პრობლემებად არ იქცევიან. კომპანიებისთვის მთავარი საქმე არის რეგულარული შემოწმების პროცედურების დაცვა. ამაში შედის გარკვეული პერიოდის მიხედვით შემოწმება და მოდულების გარემოზე ყურადღებით მოწყობა. როდესაც მომხმარებლები ამ შემოწმებების დროს პატარა პრობლემებს ხვდებიან, ეს საშუალებას იძლევა მოდულების სამუშაო ვადის გაზრდაში რეალურ გამოყენებაში. უმეტესი ინდუსტრიული საწარმო აღმოაჩენს, რომ ასეთი პროაქტიული მიდგომა ფულის დაზოგვას უზრუნველყოფს მომდევნო პერიოდში, სისტემის სანდოობის შენარჩუნებით.

Ახალ ტექნოლოგიებში ინვესტიციების განხორციელება და პერიოდულად მდგომარეობის მონიტორინგი დროთა განმავლობაში მნიშვნელოვნად განსხვავდება ოპერაციების დამაჯერებლობაში. დიაგნოსტიკური ხელსაწყოების მაგალითზე, დღეს კომპანიებს შეუძლიათ მოწყობილობების მდგომარეობის შემოწმება მათი მუშაობის პროცესში, ამიტომ პრობლემები ადრე არის აღმოჩენილი, სანამ ისინი მაჟორულ საკითხებად იქცევიან. როდესაც ნაწილები იწყებენ გატეხილობის ნიშნებს ან როდესაც რამე მიუთითებს იმაზე, რომ მალე მოხდება მისი გამართულება, გუნდები შეძლებენ ამ პრობლემების წინასწრებით ამოხსნას გასაუქმების მოლოდინის ნაცვლად. ასეთი წინასწარი განზრახვა პრაქტიკაში მართლაც ამაღლებს შედეგებს. მოწყობილობები უკეთ მუშაობს მთლიანად, შეულედ არის არაგეგმური შეჩერებების დრო და შეკეთება ბევრად იაფია ვიდრე მომდევნო სრული გამართულებების მოგვარება.

Ხელიკრული

Რა არის IGBT მოდულები გამოყენებული?

IGBT მოდულები გამოიყენება ძალის ელექტრონიკაში, რათა ეფექტურად განახრის და მართოს ელექტრო ძალი. ისინი ხშირად განხილულია განავითარებული ენერგიის სისტემებში და ელექტრო ავტომობილებში.

Რა განიცდის თერმალურ ბურთობა IGBT მოდულებში?

Თერმალური ბურთობა ხშირად გამოწვევს არაკარგული გამყავის სისტემები და ცუდი თერმალური მართვა, რაც მიიღებს უკავშირულ ტემპერატურის ზრდას.

Როგორ შეიძლება დაჭერილი ვოლტის სტრესი შეაფარდოს IGBT მოდულებში?

Დაჭერილი ვოლტის სტრესი შეიძლება შეაფარდოს ვოლტის დაცულების მექანიზმების გამოყენებით, ჩა Gaussian ცირკუიტები, რომლებიც აბსორბირებენ და განაწილებენ მეტი ენერგიას.

Რა არის IGBT მოდული გამართულების ნიშნები?

Ნიშნები 娷ს გამეტება, ელექტრონული არკინგი და ფუნქციონალური დაკარგვა. მონიტორингის მეთოდების გამოყენებით შეიძლება ინდიკირდეს პოტენციალური ვერავი.