高精度DAC CM7502のレーザー ガルバノメーターシステムへの応用

1. はじめに

レーザー検電計システムは、レーザー光の進行方向を精密に制御するために広く使用されており、レーザーマーキング、彫刻、切断および関連するアプリケーションで広範にわたって利用されています。検電計はモーター(通常は検電計用モーター)によって駆動され、反射鏡の角度を急速に変化させることで、レーザー光の位置を調整します。

デジタル-アナログ変換器(DAC)はレーザー検電計システムにおいて「橋渡し」としての役割を果たします。その中心的な機能は、デジタル制御信号を高精度のアナログ信号に変換し、検電計モーターを駆動することで、高速かつ正確なレーザー位置決めを実現することです。DACの性能は、レーザー位置決めの精度、速度、安定性を直接決定します。

CM7502(LTC2642-16と競合)は、16ビットのバッファなし電圧出力型DACです。高精度、高速出力安定性、高直線性、低ノイズといった利点を持つため、レーザー検電計アプリケーションに適しています:

高精度: 16ビットの解像度により、精密な角度制御が可能。

高速出力安定性: わずか1μsの立ち時間は、ガルバノメータシステムの動的応答にマッチし、特に高速スキャニングにおいて極めて重要です。

高直線性: 積分非直線性(INL)< ±0.4 LSB。-40°C~125°Cの全温度範囲で直線性が安定しており、正確な角度制御を実現し、位置ずれを回避します。

極めて小さいコード遷移グリッチ: DACコードの遷移時にグリッチパルスが発生しますが、CM7502は業界でも最も低いグリッチインパルスの一つを特長としており、モーター制御を滑らかに保ちます。

低消費電力: 待機電流はわずか120μA、ゼロコードオフセット誤差は0.5 LSBと小さい。

2. CM7502の特長

バイポーラ出力

シングルサプライ動作:2.7 V ~ 5.5 V

低消費電流:120 μA

INL誤差:±0.4 LSB

低グリッチインパルス:0.5 nV・s

短い整定時間:1 μs

全温度範囲にわたり、出力電圧の単調性が保証されています

電圧出力は60 kΩの負荷を直接駆動可能

50 MHz対応SPI/QSPI/MICROWIRE互換シリアルインタフェース

電源投入時のリセットにより、DAC出力がミッドスケールに設定される

nCLR非同期リセットピン

リファレンス電流補償機能

MSOP10 (3 mm × 3 mm) および DFN10 (3 mm × 3 mm) パッケージ

3. ソリューションの概要

CM7502は、2VからVDDまでの外部電圧リファレンスで動作し、非常に高い直線性(全温度範囲でのINL < ±0.4LSB)を実現しているため、角度制御にずれが生じません。また、オフセット誤差やゲイン誤差など、リファレンス電圧の影響をほとんど受けません。ゲイン誤差の温度ドリフトは、ほぼ完全に外部リファレンスの温度ドリフトによって決まります。CM7502は、独自のリファレンス電源電流補正技術を採用しており、全コード出力時におけるDACがリファレンス電源から引き出す電流の一貫性を保証しています。これにより、リファレンス電源の出力内部抵抗によってDACの優れた直線性性能が損なわれることはありません。

さらに、CM7502は、抵抗ネットワークを特にグループ化する独自の設計を採用しています。メインキャリーフリップ(0x7fff0x8000)のバースパルスは<0.5nV・sであり、同種の競合DAC製品と比較して1桁小さくなっています。これにより、スムーズなモータ制御が保証されます。

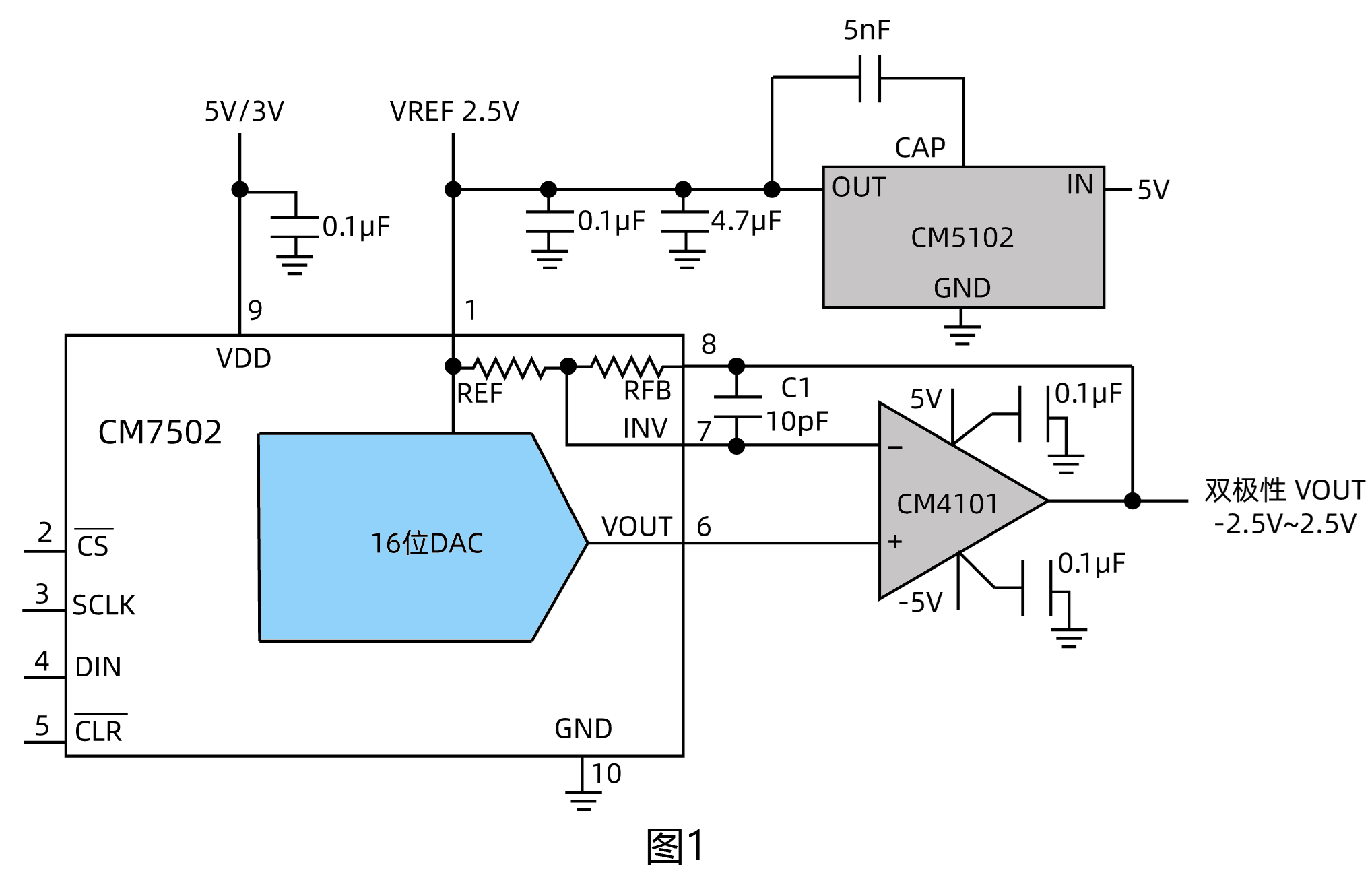

CM7502にはマッチング抵抗ネットワークが搭載されており、外部オペアンプ(CM4101)と組み合わせることで、出力範囲の1:2増幅を容易に実現できます。双極性±VREF電圧出力が可能になります。CM4101は国内製のバイポーラプロセスチップを用いたアンプで、優れた1/fノイズ特性と極めて低い広帯域ノイズを備えています。CM4101は帯域幅とスルーレートが高く、CM7502と組み合わせることで、極めて高速な出力信号の立ち上げ時間(図1参照)を実現できます。

当社は、ADC/DACと併用可能な高精度のリファレンス電圧源を幅広く提供しています。CM5102は、最大温度ドリフトが5ppm/℃(-55 ℃~125 ℃)の2.5V/3V出力バンドギャップリファレンス電圧源です。CM5405は、最大温度ドリフトが2ppm/℃(-55 ℃~125 ℃)の5V出力ツェナーリファレンス電圧源です。