Breve introducción del producto:

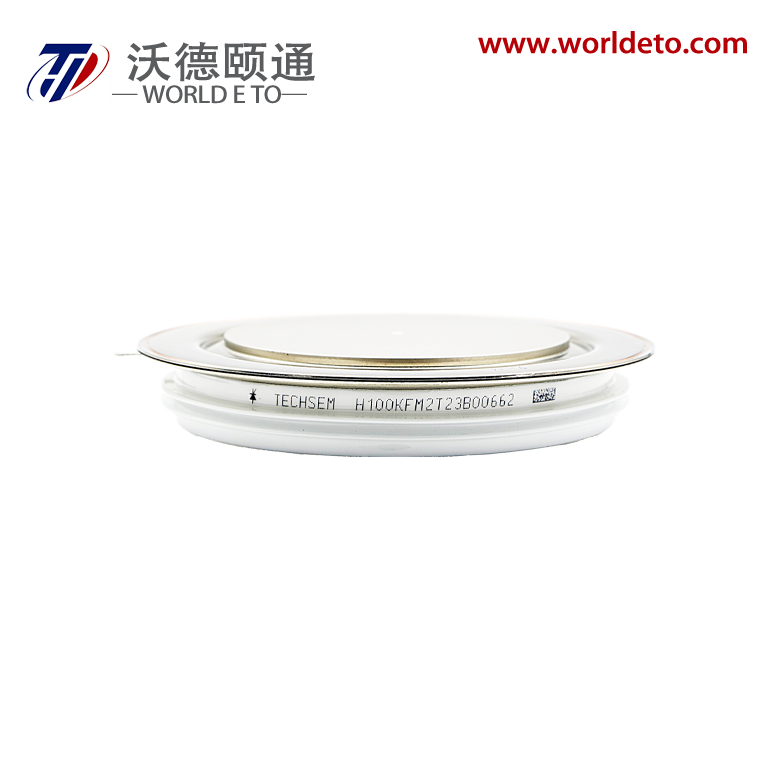

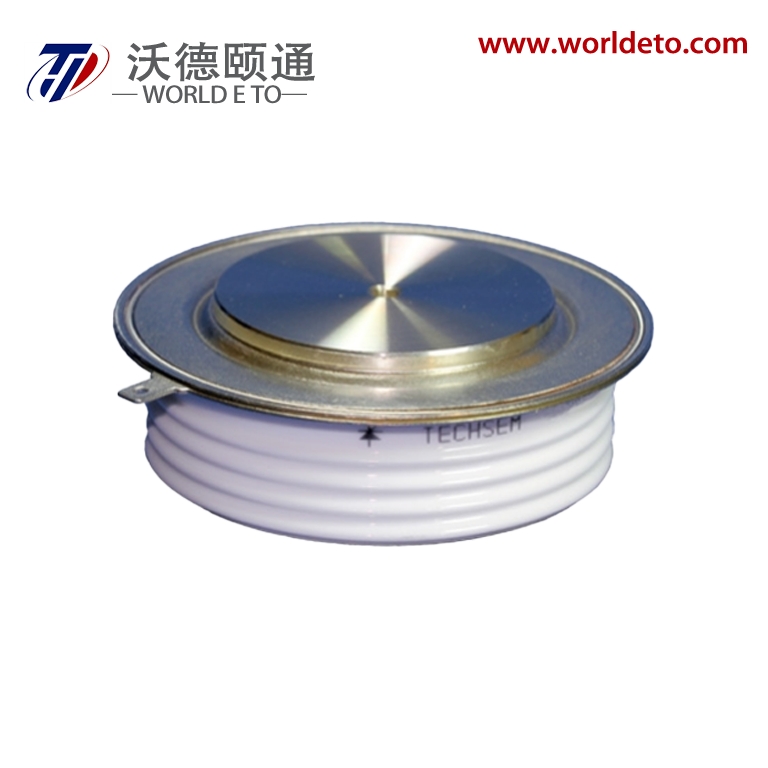

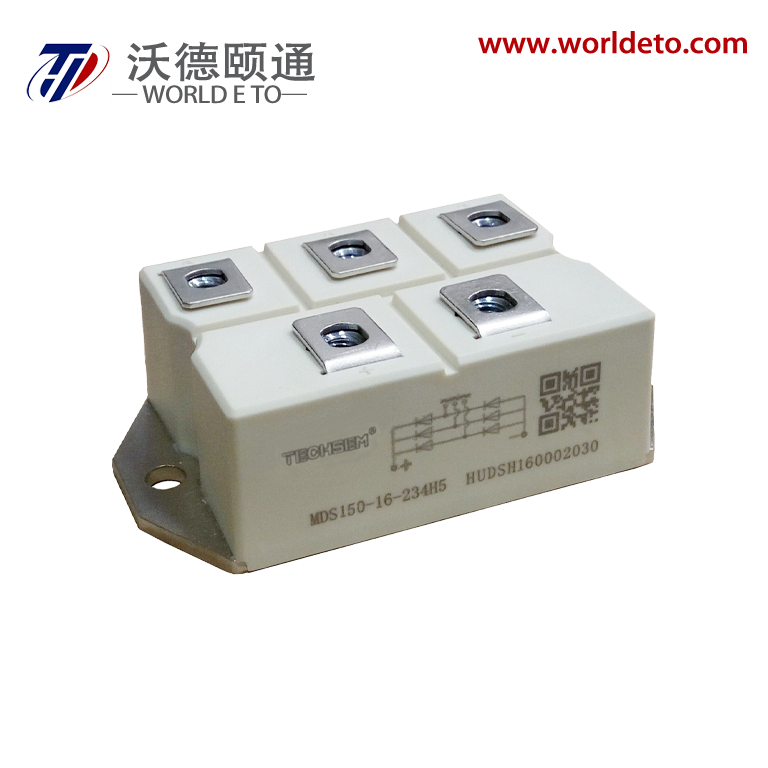

Y100KKG, 4890A, el voltaje puede alcanzar los 3000V. Producido por TECHSEM, un fabricante reconocido de tiristores en China. Este producto se utiliza ampliamente en campos como la calefacción por inducción, máquinas de soldadura, inversores, etc. Las aplicaciones industriales a gran escala de este producto en diversos campos han verificado plenamente su fiabilidad. El producto tiene una calidad estable y alta fiabilidad. Muy valorado por los usuarios.

parámetro clave

Número de pieza Y100KKG-KT100cT |

|

I T(AV)

V DRM ,V RRM

el ¿Qué es?

|

4890A

2000 V 2200 V

2500V 2800V

3000 V

40~130µs

|

Características

- Puertas amplificadoras interdigitadas

- Encendido rápido y alto di/dt

-

Bajas pérdidas de conmutación s

Aplicaciones típicas

- I inductivo calefacción

- Soldadores electrónicos

- Auto-conmutado inversor ters

|

El símbolo

|

Características

|

Condiciones de ensayo

|

Tj( ℃C) |

Valor |

UNIDAD

|

Mínimo |

Tipo |

Máx |

|

IT(AV)

|

Corriente media en estado de conducción |

180°con una frecuencia de onda senoidal media de 50 Hz, doble lado enfriado, |

TC=55°C

|

125

|

|

|

4890

|

A

|

VDRM VRRM |

Voltado de emergencia de pico repetitivo Voltado inverso de pico repetitivo |

tp=10ms

|

125

|

1900

|

|

3000

|

V

|

No puedo no puedo |

Corriente pico repetitiva |

a V DRM a V RRM |

125 |

|

|

250 |

el número de |

ITSM |

Corriente de sobrecarga en estado de conducción |

10 ms media onda senoidal VR=0,6V RRM |

125 |

|

|

62 |

kA |

El 1 de enero |

I2t para coordinación de fusibles |

|

|

19220 |

A 2s*10 3 |

VTO |

Voltaje de umbral |

|

125 |

|

|

1.30 |

V |

rT |

Resistencia de pendiente en estado de conducción |

|

|

0.28 |

mΩ |

VTM |

Voltaje pico en estado de conducción |

I TM =5000A, F=90kN |

25 |

|

|

2.90 |

V |

dv/dt |

Tasa crítica de aumento de la tensión en estado muerto |

V DM =0.67V DRM |

125 |

|

|

1000 |

V/μs |

di/dt |

Tasa crítica de aumento de corriente de estado de encendido |

V DM = 67%V DRM hasta 4000A

Impulso de puerta tr ≤0.5μs IGM=1.5A Pulso único

|

125 |

|

|

1200 |

A/μs |

¿Qué es eso? |

Cargo por recuperación |

I TM =2000A, tp=4000µs, di/dt=-20A/µs, VR=100V |

125 |

|

2400 |

|

el valor de la concentración |

tq |

Tiempo de apagado conmutado por circuito |

I TM =2000A, tp=4000µs, VR=100V dv/dt=30V/µs, di/dt=-20A/µs |

125 |

40 |

|

130 |

μs |

IGT |

Corriente de disparo de puerta |

El valor de la corriente de corriente de la corriente de corriente de corriente de corriente de corriente de corriente de corriente de corriente de corriente de corriente de corriente de corriente de corriente de corriente de corriente de corriente de corriente de corriente de corriente de corriente de corriente de corriente de corri

|

25

|

40 |

|

450 |

el número de |

Vgt. |

Voltaje de disparo de puerta |

0.9 |

|

4.5 |

V |

IH |

Corriente de mantenimiento |

20 |

|

1000 |

el número de |

El |

Corriente de retención |

|

|

1000 |

el número de |

VGD |

Voltaje de puerta no disparado |

V DM =67%VDRM |

125 |

|

|

0.3 |

V |

Rth(j-c) |

Resistencia térmica unión a carcasa |

A 180 °seno, enfriado por ambos lados Fuerza de sujeción 90kN |

|

|

|

0.005 |

℃ /W

|

Rth(c-h) |

Resistencia térmica de la caja al disipador de calor |

|

|

|

0.0015 |

- ¿ Qué? |

Fuerza de Montaje |

|

|

81 |

|

108 |

kN |

TVj |

Temperatura de unión |

|

|

-40 |

|

125 |

℃ |

TSTG |

Temperatura almacenada |

|

|

-40 |

|

140 |

℃ |

El |

Peso |

|

|

|

2000 |

|

gRAMO |

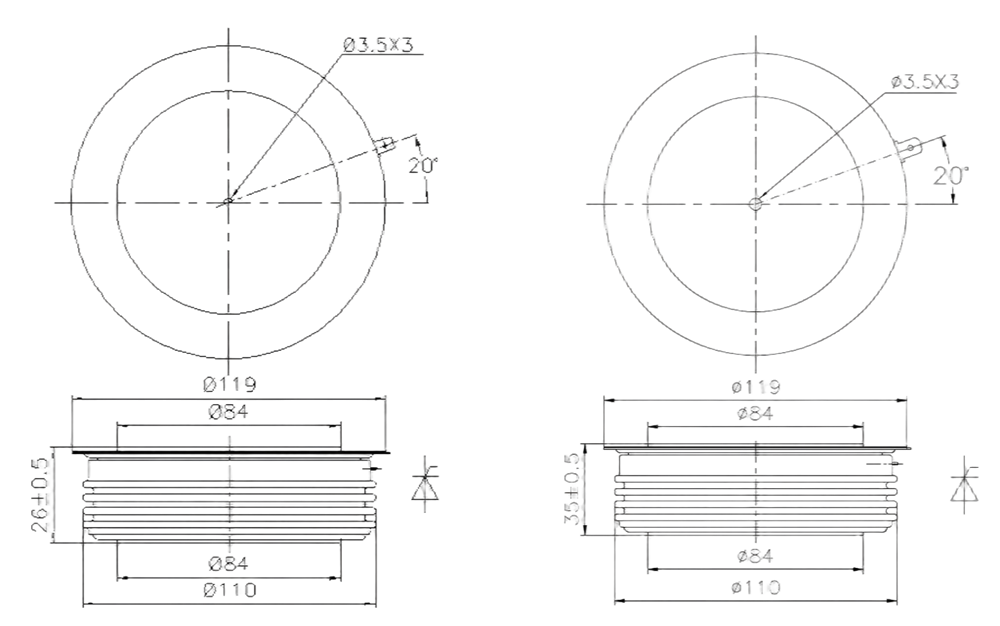

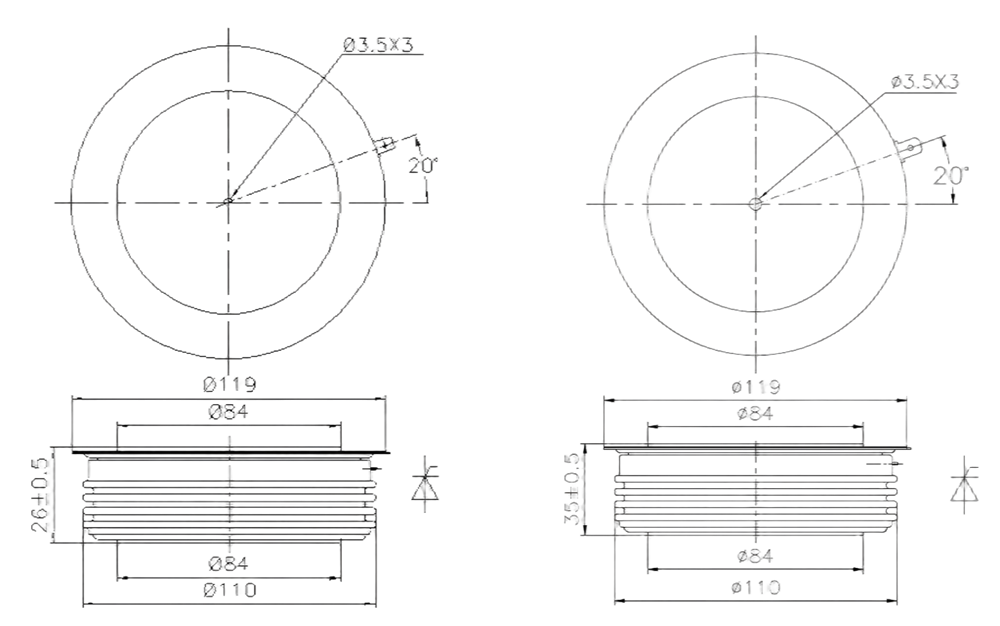

Esquema |

El número de unidades de producción |

Esquema

Laboratorio bien equipado

Disponemos de un laboratorio bien equipado para pruebas y controlamos estrictamente la calidad de nuestros productos . Esto asegura que el índice de aprobación de los productos que entregamos a los clientes alcance el 100%.

Fábrica moderna automatizada

La fábrica moderna automatizada garantiza que todos los indicadores de rendimiento de nuestros productos sean altamente consistentes, minimizando al máximo las diferencias en los parámetros de cada producto. Esto no solo asegura la confiabilidad y consistencia de nuestros productos, sino que también sirve como una garantía importante para el funcionamiento seguro y confiable de los equipos de nuestros clientes.

Capacidad productiva suficiente

La sólida capacidad integral del fabricante y su suficiente capacidad de producción garantizan la entrega puntual de cada pedido.

Por qué elegirnos?

Beijing World E To Technology Co., Ltd. es proveedor líder de productos semiconductores como módulo IGBT, IGBT discretos, chips IGBT, ADC/DAC, tiristor en China, dedicada principalmente a la distribución oficial de las marcas CRRC, Starpower, Techsem NARI. Con calificación para importación y exportación y 11 años de experiencia en esta industria, exportamos a Rusia, Emiratos Árabes Unidos y muchas otras zonas de Europa.

Contamos con estrictos criterios para la selección de fabricantes, equipos técnicos profesionales y control de calidad de los productos, garantizando el correcto funcionamiento de los proyectos de nuestros clientes en los campos del transporte ferroviario, industria eléctrica, vehículos eléctricos, inversores para motores y convertidores de frecuencia.

Mientras tanto, ayudar a los clientes a personalizar diversos tiristores y conjuntos de potencia según sus requisitos especiales de parámetros es otro componente importante de nuestra fabricación por contrato y una de nuestras ventajas.

Entrega segura

Cooperamos con las principales empresas internacionales de transporte de carga para garantizar un transporte oportuno.

Al mismo tiempo, empaquetamos cuidadosamente cada lote de mercancía que entregamos a nuestros clientes según sus requisitos, para garantizar que nuestros productos lleguen completos y sin daños.

Caso de Aplicación

Propuesta técnica: Tiristor de apagado rápido de ultra alta potencia para sistemas de calentamiento por inducción en plantas siderúrgicas

Modelo: Y100KKG-KT100cT

- Resumen ejecutivo

Esta propuesta detalla el aplicación uso de nuestro Tiristor plano de apagado rápido ( Y100KKG-KT100cT ) en un sistema de calentamiento por inducción de alta potencia en una planta siderúrgica líder. Diseñado para condiciones extremas (4.890A/2.500V), para procesos metalúrgicos avanzados.

Antecedentes del proyecto y puntos críticos

Cliente: Planta siderúrgica integrada con líneas de calentamiento por inducción para forja de palanquillas.

Sistema existente:

- Inversores basados en tiristores tradicionales con circuitos de resonancia paralela.

- Voltado de trabajo: ~ 1800 V, frecuencia: ≤ 2,5 kHz.

Puntos críticos de dolor:

- Baja eficiencia: 20-30% pérdida de energía debido a reflujo de diodos y fallas de conmutación.

- Fallas frecuentes:

- A través de fallas causadas por un alto dV/dt (que conduce a un falseado de activación) y un apagado lento (60 μs).

3. ¿Qué es esto? Solución técnica e innovaciones

Debido a acuerdos técnicos de confidencialidad. Omitir el contenido de esta cláusula.

4. ¿Qué es? Implementación y resultados

Alcance de la aplicación:

- hornos de inducción de 3 × 3,5 MW para calentar las billetas de forja (1 250 °C).

- Retrofit completo de bancos de tiristores y firmware de control.

Hitos Técnicos:

- Refinado de Alta Frecuencia (8 kHz): Reducción de pérdidas por oxidación en un 18% (del 2,1% al 1,7% de rendimiento de fusión).

- Agitación de Baja Frecuencia (1,2 kHz): Logró una homogeneidad de temperatura de ±5°C, eliminando defectos por segregación.

- Cero Fallos por Cortocircuito: Validado durante 6 meses de operación ininterrumpida las 24 horas.

5. Ventajas Competitivas

Frente a Tiristores Convencionales

- 5× mayor dI/dt: Soporta una sobrecorriente de 4.890A durante el arranque en frío sin desprendimiento.

- Enfriamiento Directo por Agua: Permite una sobrecarga del 120% durante 10 segundos (crítico para la fusión de chatarra).

6. Caso Práctico: Actualización de Línea de Inducción de Shandong Steel

Perfil del Proyecto:

- Capacidad: Línea de calentamiento de billetes de 50 t/h (en operación desde 2023).

- Tiristores: 12 × RST-4890/2500-F por horno.

- Resultados:

- ROI: 8 meses mediante ahorros de energía/mantenimiento.

- Tiempo de actividad en producción: 99,2% (frente al 89,5% antes de la actualización).

- Premios: Premio Shandong a la Innovación Industrial 2024.

7. Conclusión y próximos pasos

El Y100KKG-KT100cT redefine los estándares de tiristores de ultra alta potencia para calentamiento por inducción mediante:

① Resolviendo fallos de conmutación de décadas de antigüedad;

② Habilitación de procesos metalúrgicos multifrecuencia;

③ Reducción de costos del ciclo de vida en un 30%.

Recomendación: Implementación piloto en un horno con garantía de rendimiento de 36 meses. Nuestros ingenieros proporcionarán:

- Simulación de esfuerzo térmico por elementos finitos (FEA) para el diseño del gabinete;

- Informes de prueba dI/dt (según IEEE 1460);

- Capacitación para equipos locales de mantenimiento.

Declaración solemne:

Este caso tiene como objetivo proporcionar a los usuarios una breve explicación de la aplicación de nuestro tiristor en un proyecto específico.

No nos hacemos responsables por cualquier pérdida económica causada por la implementación de proyectos que repliquen esta solución técnica.