транзистори реле

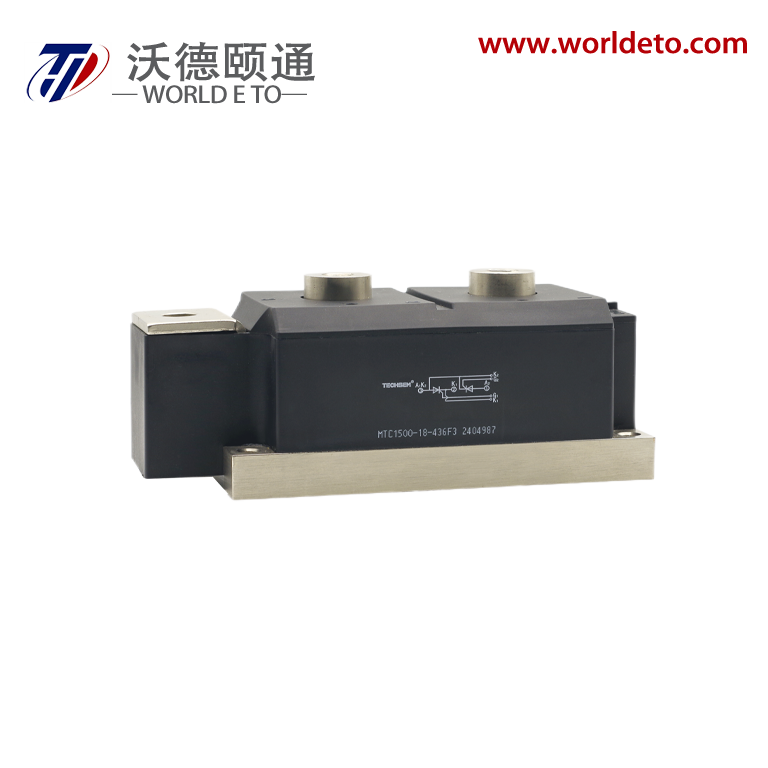

Транзисторски реле представља револуционарни напредак у електронској технологији преласка, комбинујући поузданост традиционалних електромагнетних релеја са брзином и ефикасношћу чврстог стања компоненти. Овај софистицирани уређај користи транзисторе као примарни елемент за прекидање, елиминишући механичке контакте који се налазе у конвенционалним релејима, док се одржава електрична изолација између контролних и оптерећења кола. Транзисторски реле ради користећи улазни сигнал ниске снаге за контролу излазног кола велике снаге путем полупроводничке технологије. Када се улазни напон примени на контролне терминале, унутрашњи транзистор брзо прелази између проводног и непроводног стања, ефикасно отварајући или затварајући пут излазног кола. Овај електронски механизам за прекидање пружа супериорне карактеристике у поређењу са механичким алтернативама. Модерни транзисторски релеји укључују напредне заштитне карактеристике, укључујући заштиту од пренапоретка, заштиту од обрнуте поларности и могућности топлотног искључења. Ови уграђени заштитни уређаји осигурају поуздано функционисање чак и у тешким условима животне средине. Недостатак механичких покретних делова значајно смањује хабање, што доводи до продуженог циклуса оперативног живота који може прећи милионе операција прекидања. Производствени процеси за транзисторске релеје користе прецизне технике израде полупроводника, обезбеђујући доследне параметре перформанси у свим производњима. Мерке за контролу квалитета укључују свеобухватне протоколе за тестирање који потврђују брзине преласка, способности управљања оптерећењем и карактеристике изолације. Комплектни форм модула транзисторских релеја чини их идеалним за апликације са ограниченим простором где традиционални електромагнетни релеји нису практични. Интеграционе могућности омогућавају беспрекорно уграђивање у дигиталне контролне системе, опрему засновану на микропроцесорима и аутоматизоване машине. Температурна стабилност остаје одлична у широким опсеговима рада, обично од -40 °C до +85 °C, што технологију транзисторског релеја чини погодном за и унутрашње и спољашње апликације. Потрошња енергије током операције у стању спремања је минимална, што доприноси целокупној енергетској ефикасности система.